MAINTENANCE

TROUBLE SHOOTING

14

Note:

New carbon brushes tend to spark when

first used until they wear and conform to the

motor’s armature.

WARNING!

If the supply cord of this power tool is

damaged, it must be replaced only by a

qualified service technician.

Use only a clean cloth and mild detergent to clean the

body of the polisher. Do not use solvents. Do not

immerse any part of the tool in liquid.

g. Replace the Carbon Brush Covers. Do not over

tighten.

7.

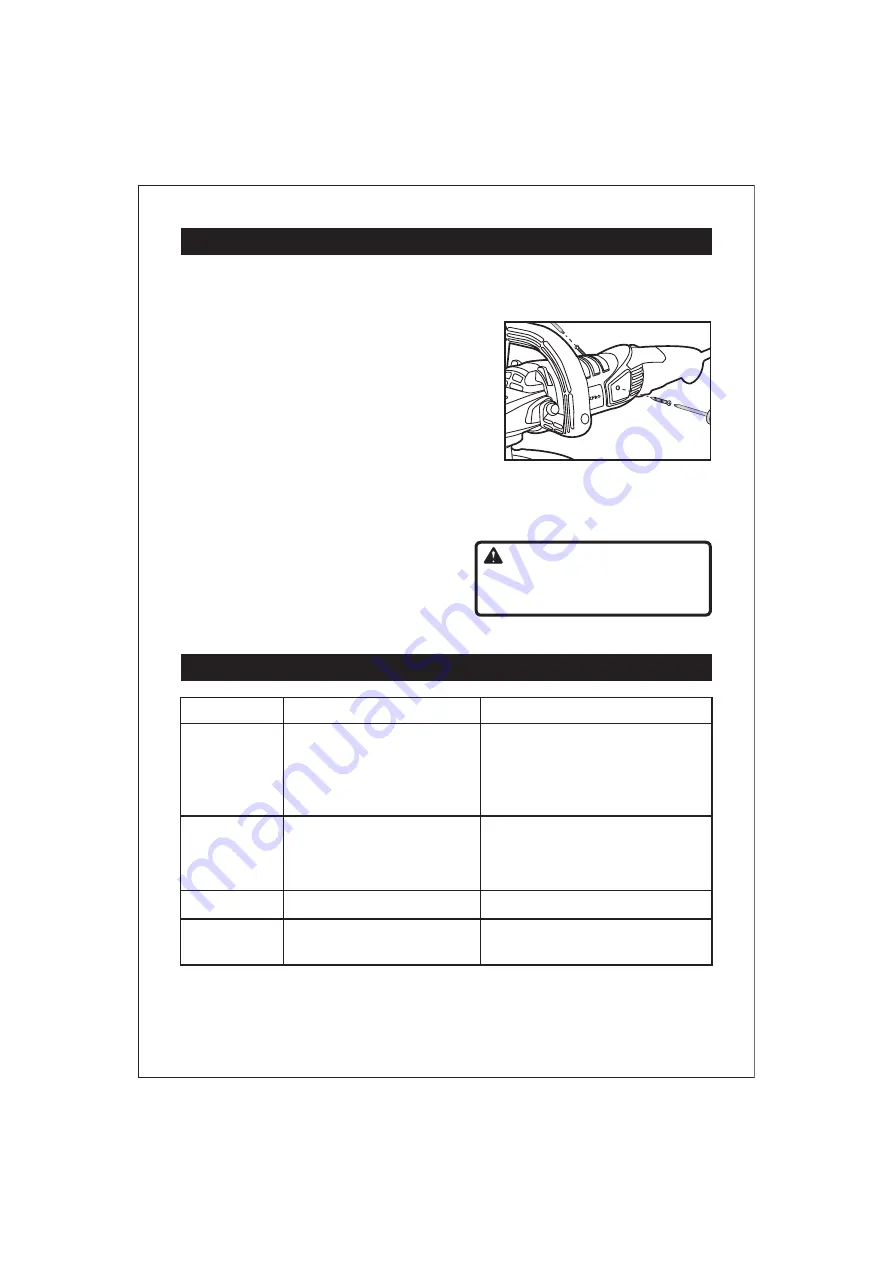

CARBON BRUSH MAINTENANCE.

The carbon

brushes may require maintenance when the motor

performance of the tool decreases or stops working

completely. To maintain the brushes:

a. Remove the carbon brush cover on each side of

the motor housing.

b. Remove the carbon brushes from the housing.

Keep track of which orientation the old carbon

brushes were in to prevent needless wear if they

will be reinstalled.

c. If either carbon brush is worn down by more than

1/2, replace them both.

d. To clean old carbon brushes before reusing them,

rub the contact areas with a pencil eraser.

e. Reinsert the old carbon brushes in the same

orientation to reduce wear.

f. When installing, make sure the carbon portions of

the brushes contact the motor armature, and that

the springs face away from the motor. Also, make

sure the springs operate freely.

8.

Problem

Tool will not start.

Tool operates slowly.

Performance

decreases over time.

Excessive noise

or rattling.

Carbon brushes worn or damaged.

Internal damage or wear.

(Carbon brushes or bearings,

for example.)

Replace brushes.

Have technician service tool.

1. Cord not connected.

2. No power at outlet.

3. Internal damage or wear. (Carbon

brushes or switch, for example.)

1. Excess pressure applied to workpiece.

2. Power being reduced by long or

small diameter extension cord.

1. Check that cord is plugged in.

2. Check power at outlet. If outlet is unpowered,

turn off tool and check circuit breaker.

If breaker is tripped, make sure circuit is right

capacity for tool and circuit has no other loads.

3. Replace carbon brushes and/

or have technician service tool.

1. Decrease pressure, allow tool to do the work.

2. Eliminate use of extension cord.

If an extension cord is needed, use one with

the proper diameter for its length and load.

See extension cords in GROUNDING section.

Possible Causes

Likely Solutions