12

17

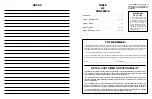

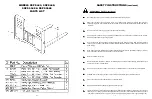

MODEL

PF-448

SSPF-3748

SSPF-3755

SSPF-3760

SSPF-442

SSPF-448

SSPF-5548

SSPF-5560

GLPF-442

GLPF-448

GLPF-5548

GLPF-5560

JDPF-5442

JDPF-5448

JDPF-5460

JDPF-6748

JDPF-6760

JDPF-H48048

JDPF-H48060

CAPACITY

4,000#

4,000#

5,500#

5,500#

4,000#

4,000#

5,500#

5,500#

4,000#

4,000#

5,500#

5,500#

4,000#

4,000#

5,500#

5,500#

5,500#

7,500#

7,500#

FORK LENGTH

48”

48”

48”

60”

42”

48”

48”

60”

42”

48”

48”

60”

42”

48”

60”

48”

60”

48”

60”

The operator is responsible for the safe operation of

this equipment. The operator must be properly trained.

Operators should be familiar with the power unit, loader

and loader attachment, and all safety practices before

starting operation. Read the safety rules and safety signs

on pages 3-11.

NOTE: Loose items such as logs can slide sideways,

thus putting all their weight on one fork. This can

bend forks.

WARRANTY DOES NOT COVER

BENT FORKS.

INSTRUCTIONS

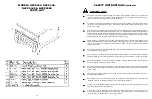

TRACTOR AND LOADER/SKID

STEER REQUIREMENTS AND

PREPARATION

——————————————————

The required size of the tractor and front loader or skid

steer will be determined by the weight of the load to be

handled.

Always use a tractor and front loader or skid steer large

enough to safely handle the load.

Check your tractor and front loader or skid steer to

make sure they are in good working condition. Check all

frame mounting bolts to make sure they are tight.

Loaders that attach to the tractor frame rails should

have a cross-tie installed for stability.

Check the hydraulic system. Be sure the hydraulic oil

and filter have been serviced according to the manufac-

turer’s recommendations.

Be sure tires and rims are in good condition. Inflate

tires to the proper recommended air pressure.

When lifting loads with a tractor front loader, it is always

best to have a heavy implement or weight box connected

to the rear 3 pt. hitch.

The load rating of all pallet forks is figured with the load

24” in front of the fork lift frame and evenly distributed

between the two fork tines.

NEVER put load at the ends of the fork tines – the lift

capacity at the ends of the forks is only about 1/3 of the

total lift capacity.

■

■

Power unit must be equipped with ROPS or ROPS

cab and seat belt. Keep seat belt securely fastened.

Falling off power unit can result in death from being

run over or crushed. Keep foldable ROPS systems in

“locked up” position at all times.

■

■

A heavy load can cause instability in driving a

power unit. Make sure the rear of the tractor is

properly counter-balanced with weights. Always

drive slowly – especially around turns. An unstable

unit could steer badly and possibly tip over, causing

injury or death.

■

■

Do not exceed the maximum recommended

weight listed for the pallet fork. Damage to the equip-

ment or serious personal injury could result.

WARNING

The JDPF-6748 and the units above that have Class II

rail mounted forks. The JDPF-H48048 and JDPF-H48060

models have Class 3A forks. The load rating for all units

is with the load halfway in front of the pallet fork frames

(ie - 24” on 48” forks).

PALLET FORK LOAD RATING

INSTRUCTIONS

(continued)

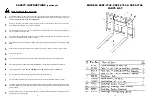

MODELS JDPF-5442/5448/5460

ATTACHMENT TO PRIME MOVER

——————————————————

The Pallet Fork Models JDPF-5442, JDPF-5448, and

JDPF-5460 are specifically designed for John Deere 400

and 500 series loaders. They are rated for loads up to

4,000 lbs. Note that the JDPF-5460 forks are rated above

the loader capacity.

NOTE: Procedure is the same for all attachments.

Bucket attachment shown.

ATTACHING

1. Extend bucket tilt cylinders to angle attaching brackets

forward.

NOTE: Angle must be greater than that of the

brackets on the rear of the pallet fork.

2. Drive forward, adjusting loader height and position

until the top of the loader bracket engages the hooks

(C) on the pallet fork.

3. Slowly retract the bucket tilt cylinders and raise the

loader so the lower lock pins (F) engage the hole in

the holder strap (E).

4. Continue to retract the tilt cylinders and raise the

loader until the main frame of the pallet fork is vertical.

5. Engage tractor parking brake and/or place transmis-

sion in PARK. Shut off tractor engine and remove key.

6. Install the quick-lock-pin (A) into the pins (F) on each

side of the pallet fork.

Installation is now complete.

NOTE: On attachments with two pins (F), the 400

series loaders will utilize the upper pin and the 500

series loader will utilize the lower pin.

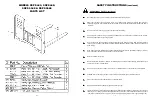

DETACHING

1. Engage tractor parking brake and/or place transmis-

sion in PARK. Shut off tractor engine and remove key.

2. Remove the quick lock-pin (A) from each side of

attachment. Store pins in storage position (B).

3. Start engine and lower the pallet fork to the ground.

Extend bucket tilt cylinders until pin (F) releases from

holder strap (E) on each side of attachment. Lower the

loader until holder brackets are free from the hooks.

Back tractor away from attachment.

4. Set parking brake and/or place transmission in PARK.

Shut off engine and remove key.

■

■

Always install the quick lock pins on the John

Deere 400, and 500 series loaders. Failure to install

the lock pins may cause injury or death caused by

falling attachment.

■

■

Do not exceed loader or attachment lift capacity.

WARNING