14

15

MODELS SSPF-3748, SSPF-3755,

SSPF-3760, SSPF-442 / 448,

SSPF-5548 & SSPF-5560

——————————————————

The Skid Steer Pallet Fork Models SSPF-3748, SSPF-

3755, SSPF-3760, SSPF-442/448, SSPF-5548, and

SSPF-5560 are designed for skid steer power units or

tractor loaders having the universal bucket quick attach

system.

The Models SSPF-3748, SSPF-442 and SSPF-448 pal-

let forks can handle loads up to 4,000 lbs. The Models

SSPF-5548/5560 and SSPF-3755/3760 are rated for

loads up to 5,500 lbs. These models are for the standard

size skid steer units and tractors above 40 hp. Load rat-

ings are figured at half the length of the tines.

The Models SSPF-3748, SSPF-3755 and SSPF-3760

have a bolt-in center section creating a one piece back-

stop. This center section maybe removed to convert the

frame to a step through design.

Make sure latch pins engage slots to lock the frame in

place.

Connection instructions are on page 15.

MODEL PF-448

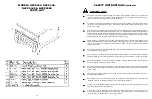

ASSEMBLY – QUICK ATTACH

——————————————————

If your tractor loader has a bucket Quick Attach feature,

check with your dealer on the availability of adapter

brackets for your brand and model loader.

Measure the width of the front adapter on your loader

and locate the Quick Attach brackets on the main frame.

Locate these brackets so the main frame will be centered

on your loader.

Tighten the U-bolts that connect the brackets to the

main frame.

Parts drawing for the PF-448 is on page 21.

Install the two backstop weldments on the top crossbar.

INSTRUCTIONS

(continued)

INSTRUCTIONS

(continued)

MODELS SSPF-442/448 &

SSPF-3748/3755/3760

ATTACHMENT TO PRIME MOVER

——————————————————

3. Enter the prime mover. Fasten seatbelt, start engine.

Disengage the parking brake.

4. Follow the attaching procedure in the prime mover

owner's manual. Align the attachment mechanism

with the mounting on the pallet fork, attach to the

prime mover on loader.

5. Engage the parking brake and shut down the prime

mover. Be sure to relieve pressure to the auxiliary

hydraulic lines.

6. Unfasten safety restraints and exit the prime mover.

7. Engage the latching mechanism to secure attachment

to loader. The lockpins must be completely extended

and secured into the retaining slots.

8. Re-enter the prime mover. Fasten seatbelt and re-

start engine.

1. Position the attachment on a level surface.

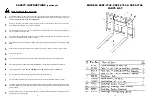

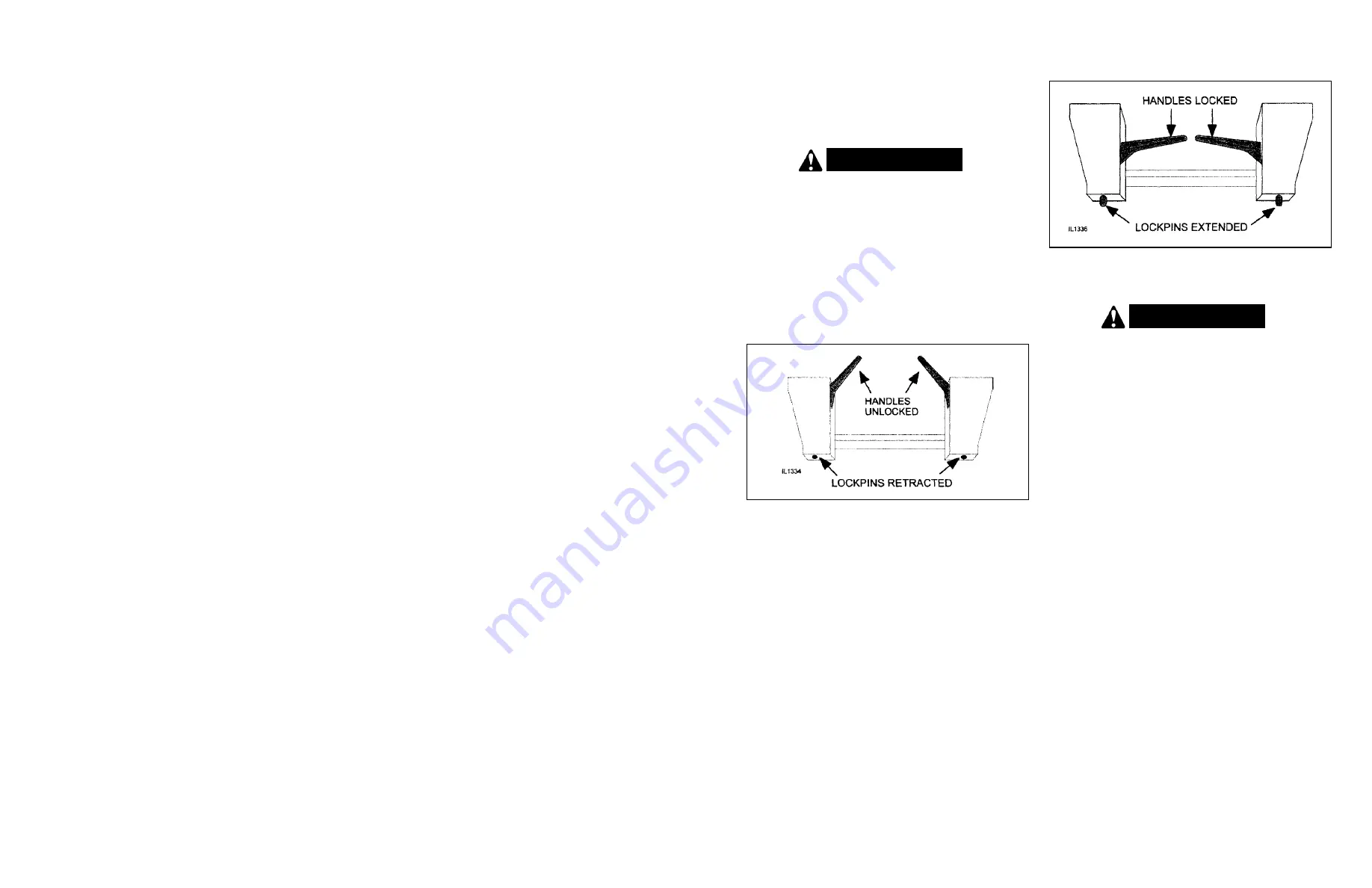

2. The quick attach coupler handles should be in the

unlocked position with lock pins retracted, Figure 2.

Improper attachment of the Pallet Fork could result

in injury or death. Do not operate this product until

you have positive indication that the attachment is

securely mounted.

Attachment coupler handles must always be

rotated to LOCK POSITION to prevent coupler latch

from disengaging and attachment from falling off.

Figure 2. Quick Attach Coupler Handles - Unlocked

Figure 3. Attachment Coupler Handles - Locked

9.

Carefully raise the loader and cycle the rollback/tilt

cylinders to check clearances and to ensure that the

attachment is securely mounted.

REMOVING THE PALLET FORK

1.

If possible, find a level solid location to place the

attachment. This makes it easier to disconnect and

re-connect later on.

2.

Lower the attachment to the ground.

3.

Engage the parking brake and shut down the prime

mover. Be sure to relieve pressure to the auxiliary

hydraulic lines.

4.

Unfasten safety restraints and exit prime mover.

5.

Disengage attachment-locking mechanism (mechan-

ical type).

6.

Enter prime mover, fasten safety restraints and start

the prime mover.

7.

Disengage attachment-locking mechanism (hydraulic

type).

8.

Disengage the parking brake, and back away from

the attachment.

WARNING

WARNING

OBEY ALL

SAFETY

WARNINGS!

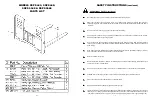

MODELS GLPF-442/448/5548/5560

ATTACHMENT TO PRIME MOVER

——————————————————

The Models GLPF-442, GLPF-448, GLPF-5548, and

GLPF-5560 are specifically designed for tractor front

loaders with the Euro or Global bucket quick-change

system.

The Models GLPF-442/448 have a load rating of 4,000

lbs.

The Models GLPF-5548/5560 have a load rating of

5,500 lbs.

Connection instructions are on page 16.

MODELS JDPF- 5442/5448/5460

ATTACHMENT TO PRIME MOVER

——————————————————

The Pallet Fork Models JDPF-5442, 5448, and 5460 are

specifically designed for John Deere 400 and 500 series

loaders. They are rated for loads up to 4,000 lbs.

Connections instructions are on page 17.

MODEL JDPF-6748 & JDPF-6760

ATTACHMENT TO PRIME MOVER

——————————————————

The Models JDPF-6748 and JDPF-6760 pallet forks are

specifically designed for John Deere 600 and 700 series

loaders with quik-change latches. They have a load rating

of up to 5,500 lbs.

Connections instructions are on page 18.

MODELS JDPF-H48048 & H48060

——————————————————

These two models are designed for the John Deere

H480 loader. The Model JDPF-H48048 has 48" long fork

tines and the Model JDPF-H48060 has 60" long fork

tines. Both models are rated at 7,500 Ib. with the load 24"

in front of the fork frame and evenly distributed on the two

fork tines.

The connection to the loader is the Global Series II.

The forks are 1.75" x 4.75" width Class Ill solid type

forks that are sliding adjustable on a 50" wide carriage.

Connection instructions for the JDPF-H480 Models are

similar to the ones for the standard Euro or Global units.

(See page 16.)