J0Z-SP38-1016/90891

AFTER-SALES SERVICE

GB 0845 872 2740

www.coreservice.co.uk

IRL 019022605

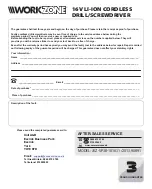

The tool has two mechanical speeds that can be selected using the switch (3).

1st speed setting:

Slide the switch (3)

away from the drill chuck (1).

The number "1" will be displayed on the

switch. (Fig I)

Selecting the 1st speed setting

In the 1st speed setting, the drill/screwdriver works at a low rotational speed and a high

torque. This setting is used for drilling large drill diameters, for

drilling into wood and plastic as well as the screwdriver function.

2nd speed setting:

Slide the switch (4) towards

the drill chuck. The number "2" will be displayed

on the switch.(Fig. J)

Selecting the 2nd speed setting

In the 2nd speed setting, the drill/screwdriver works at a high rotational speed and a low

torque. This setting is used for drilling small drill diameters and drilling into metal.

Setting the torque

CAUTION! Damage to the tool

Never change the torque while the tool is in operation; this can cause damage.

• Operate the torque preselection ring (2) only when the drill/screwdriver has

come to a standstill.

When tightening and loosening screws, select a low torque to avoid damages to the work

piece (particularly work pieces made of wood) or to the screw.

Select the drill setting for drill work (drill symbol), see section

"Setting the torque for drilling".

Note: Test object

First carry out a trial on a test object, not your actual work piece, and set the required

torque before beginning the actual work.

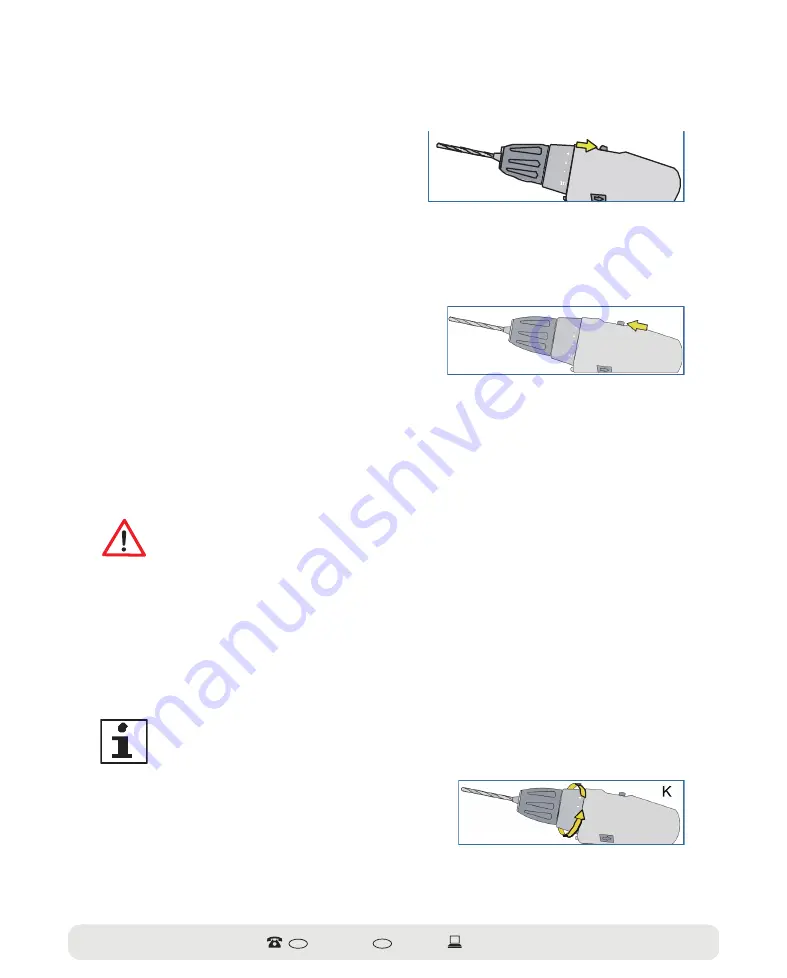

Using the torque preselection

ring (2) select the appropriate

torque for your work piece. (Fig. K)

Setting the torque

K