WDHD3S Kit Assembly Instructions

9

Figs.

7 / 11

FIT THE DIL SWITCHES.

Orientation is important

-

note the

“

on

”

printed on the PCB and

on the switches (the individual switches

“

1

”

and

“

12

”

are also

printed as legends on the PCB). Be very careful when soldering

not to accidentally link across solder points with excess

solder.

FIT ALL THE CAPACITORS.

Note that the electrolytic capacitors C1, C2, C3, C4, C5, C7, C8

are polarized, and ensure they are fitted correctly. The PCB is

printed with a

+

sign where polarity needs to be observed. The

capacitors are normally printed with a white (occasionally black

or gold) bar which denotes the negative terminal as shown below.

FIT THE HEATER LINKS.

We have highlighted the solder points for the heater links in

white on the photograph at Fig. 7 so that you can find them

easily. Note that the links should be fitted to the

solder

side

of the PCB and care should be taken to ensure that the sharp

ends of the components, where they are soldered through the PCB,

do not damage the insulation of the wires. Taking twisted pairs

of brown and grey wire, use the brown wires to connect point

HTR

+

(next to pin HTR

+

OR) to HTR

+

at V2 and onwards to HTR

+

at

V1. Similarly, using the grey wires, connect HTR

-

(next to pin

HTR

-

OR) to HTR

-

at V2 and onwards to HTR

-

at V1.

(

“

HTR

+

”

and

“

HTR

-

”

are, in fact misprints on the PCB

-

the

heaters operate on AC)

-

but the markings make it easier to wire

the heaters of both valves the same way round.)

FIT THE LED.

Solder approx 75

-

100mm red wire to the long leg of the LED and a

similar length of black wire to the short leg. Insulate the

joints and the bare legs of the LED with heat

-

shrink sleeving.

Twist the wires together to provide mechanical stability and

solder the red wire to the LED

+

pin and the black to the LED

-

pin on the PCB. The LED can be passed through the hole in the

chassis ready for fixing to the fascia when you come to do this.

Because access is restricted later, solder approx 100mm red wire

to each of the pins OPL and OPR, and a similar length of black

wire to pins OPLG and OPRG.

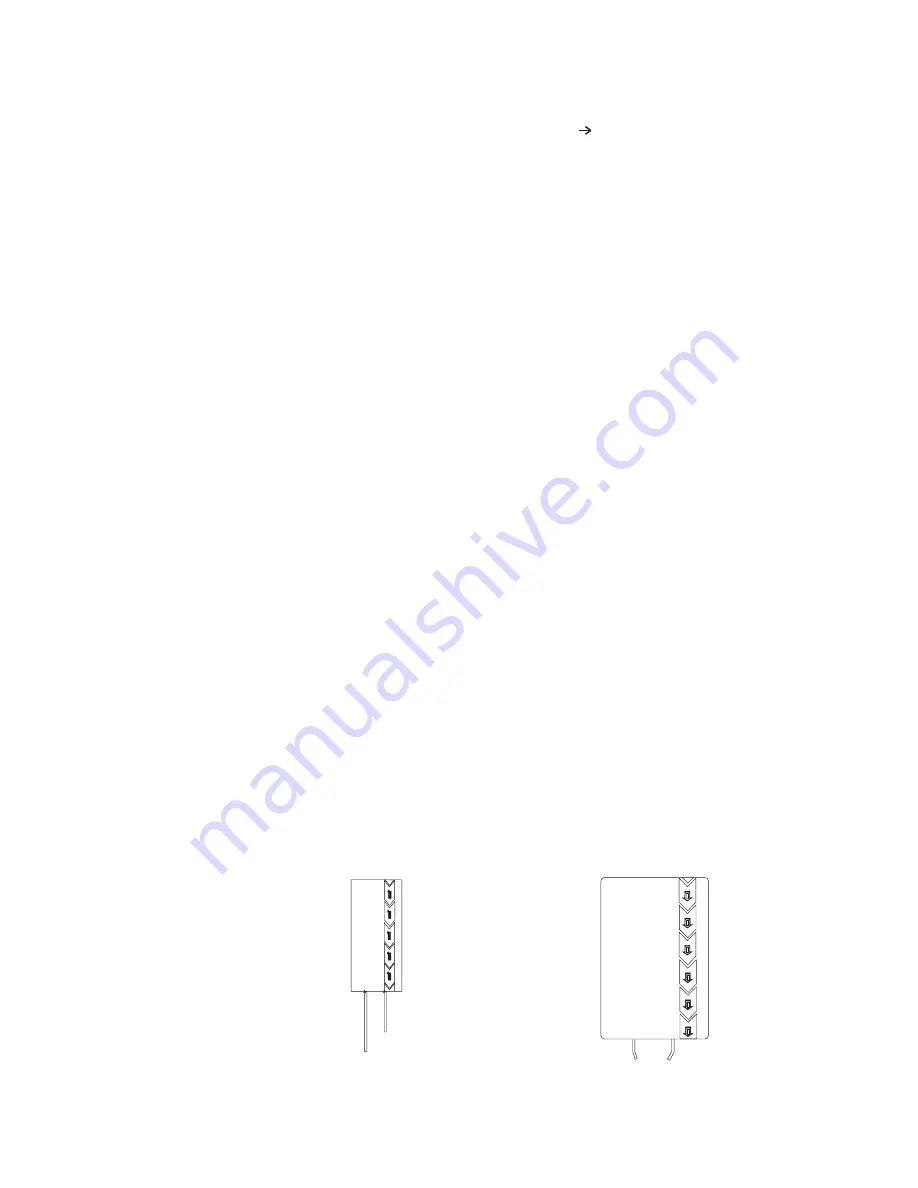

(-) negative terminal

(+) positive terminal

(-) negative terminal

(+) positive terminal

Fig. 9

Capacitor Polarity Markings for C4, C5, C7, C8 (left)

and C1, C2, C3 (right)

Fig.10

Figs.

9 / 10

WDHD3S Kit Assembly Instructions

9

Figs.

7 / 11

FIT THE DIL SWITCHES.

Orientation is important

-

note the

“

on

”

printed on the PCB and

on the switches (the individual switches

“

1

”

and

“

12

”

are also

printed as legends on the PCB). Be very careful when soldering

not to accidentally link across solder points with excess

solder.

FIT ALL THE CAPACITORS.

Note that the electrolytic capacitors C1, C2, C3, C4, C5, C7, C8

are polarized, and ensure they are fitted correctly. The PCB is

printed with a

+

sign where polarity needs to be observed. The

capacitors are normally printed with a white (occasionally black

or gold) bar which denotes the negative terminal as shown below.

FIT THE HEATER LINKS.

We have highlighted the solder points for the heater links in

white on the photograph at Fig. 7 so that you can find them

easily. Note that the links should be fitted to the

solder

side

of the PCB and care should be taken to ensure that the sharp

ends of the components, where they are soldered through the PCB,

do not damage the insulation of the wires. Taking twisted pairs

of brown and grey wire, use the brown wires to connect point

HTR

+

(next to pin HTR

+

OR) to HTR

+

at V2 and onwards to HTR

+

at

V1. Similarly, using the grey wires, connect HTR

-

(next to pin

HTR

-

OR) to HTR

-

at V2 and onwards to HTR

-

at V1.

(

“

HTR

+

”

and

“

HTR

-

”

are, in fact misprints on the PCB

-

the

heaters operate on AC)

-

but the markings make it easier to wire

the heaters of both valves the same way round.)

FIT THE LED.

Solder approx 75

-

100mm red wire to the long leg of the LED and a

similar length of black wire to the short leg. Insulate the

joints and the bare legs of the LED with heat

-

shrink sleeving.

Twist the wires together to provide mechanical stability and

solder the red wire to the LED

+

pin and the black to the LED

-

pin on the PCB. The LED can be passed through the hole in the

chassis ready for fixing to the fascia when you come to do this.

Because access is restricted later, solder approx 100mm red wire

to each of the pins OPL and OPR, and a similar length of black

wire to pins OPLG and OPRG.

(-) negative terminal

(+) positive terminal

(-) negative terminal

(+) positive terminal

Fig. 9

Capacitor Polarity Markings for C4, C5, C7, C8 (left)

and C1, C2, C3 (right)

Fig.10

Figs.

9 / 10