Maintenance—Every 100 Hours

DH10862,000017D -19-11MAY18-1/1

Inspect and Re-Torque Track Hardware

Each inspection and re-torquing should be documented

by completing a service report for each unit, placing a

copy of this report in the machine file, and forwarding a

copy to the manufacturer’s attention.

For shoes with missing or loose cap screws and nuts,

remove shoes and clean the mating surface of shoes

and links before replacing cap screws and nuts. The

cap screws must be replaced because they have been

stretched to yield previously.

IMPORTANT: Prevent possible machine damage.

Operating a machine with loose shoes can

cause the cap screws and holes in the shoes

and links to wear, making it difficult to keep

the shoes tight. Loose shoes can also cause

hardware malfunction and loss of shoes.

Improper track shoe cap screw torque will

result in serious damage to the undercarriage

components, shorter life expectancy, and

will void the manufacturer's warranty on the

undercarriage components.

Checking Track Shoe Hardware Torque

NOTE: This procedure is for checking the torque

specification on existing track shoe hardware.

1. Tighten cap screws in sequence to specification.

Specification

Cap Screw—Torque..................................................................1556 N·m

1148 lb·ft

2. Cap screws that have turned have reduced tightness

and need to be re-torqued. See Re-Torquing Track

Shoe Hardware. (Section 3-6.)

3. Check track shoe holes for wear or damage. Replace

as necessary.

Re-Torquing Track Shoe Hardware

NOTE: This procedure is for re-torquing existing track

hardware that was found loose during the Checking

Track Shoe Hardware Torque procedure.

1. Loosen cap screw.

2. Tighten cap screws in sequence to specification.

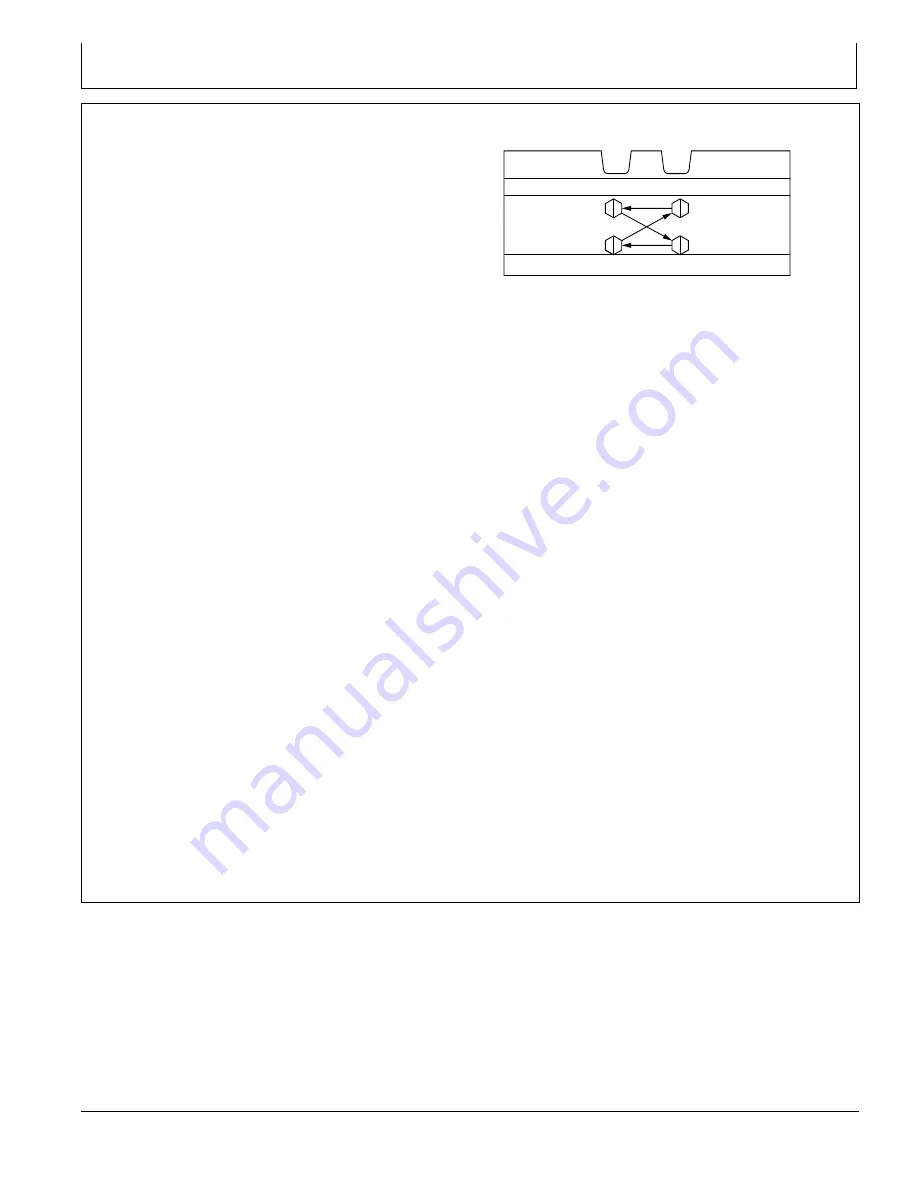

TX1255661

—UN—19APR18

Cap Screw Torque Sequence

Specification

Cap Screw—Initial

Torque.........................................................................................136 N·m

100 lb·ft

3. Re-torque cap screws in sequence to specification.

Specification

Cap Screw—Final

Torque............................................................ 407 N·m + 1/3 Turn (120°)

300 lb·ft + 1/3 Turn (120°)

Torquing Replacement Track Shoe Hardware

IMPORTANT: Prevent possible machine damage.

Clean shoe and link surfaces of dirt, paint,

and debris before installation.

NOTE: This procedure is for installing and torquing new

track shoe hardware to specification.

1. Clean shoe and link surfaces of dirt or paint.

2. Tighten cap screws in sequence to specification.

Specification

Cap Screw—Initial

Torque.........................................................................................136 N·m

100 lb·ft

3. Torque cap screws in sequence to specification.

Specification

Cap Screw—Final

Torque............................................................ 407 N·m + 1/3 Turn (120°)

300 lb·ft + 1/3 Turn (120°)

3-6-1

092221

PN=159

Summary of Contents for 380GLC

Page 6: ...Introduction Continued on next page TX JDEULA 19 11JUL16 2 3 TX1219046 UN 11JUL16 092221 PN 6...

Page 7: ...Introduction TX JDEULA 19 11JUL16 3 3 TX1219047 UN 14JUL16 092221 PN 7...

Page 9: ...Introduction DX EMISSIONS EPA 19 12DEC12 2 2 TS1721 UN 15JUL13 092221 PN 9...

Page 17: ...Introduction DX EMISSIONS CARB 19 26AUG20 8 8 RG32759 UN 19AUG20 092221 PN 17...

Page 24: ...Introduction 092221 PN 24...

Page 287: ...Index Index 11 092221 PN 11...

Page 288: ...Index Index 12 092221 PN 12...