CS200

Control Systems

20

This section of the operating manual is for Worthington Industries approved equipment that uses the CS200

SERIES Control System.

Introduction

The CS200 Control System, temperature and LN

2

level controller is designed for easy operation and reliable

uninterrupted service. This controller will maintain the selected liquid level range of LN

2

in your freezer as

well as providing audible and visual alarms for any non-conforming conditions that may occur. An Alarm is

any condition outside the activated preset limits on the control, such as an open sensor circuit or temperature

alarm. “System

Events

” are lid openings and closings, solenoid valve openings and closings, and operation

of the controller’s relay for remote alarm indication. System Events, Alarms and Temperature “

Data

” can be

downloaded.

The System should require no additional attention to maintain liquid level if an adequate supply source of

liquid nitrogen is available. If your protocol calls for you to “top-off” the Cryostorage System at the end of

a workday or workweek, press the FILL button. The unit will fill to the upper allowable liquid level and stop

automatically. You may choose to manually stop the fill by pressing the STOP button at anytime during the fill.

Operation Data

The CS200 CONTROL SYSTEM stores data related to the operation of the Worthington Industries Cryostorage

freezer. This data includes date, time, LN

2

level, temperature, system events and error conditions. This can be

useful for audit purposes, operation analysis and preventive maintenance.

Communications

The CS200 CONTROL SYSTEM has been designed with advanced communications capabilities. This allows

for the transfer of data out of the control where the data can more easily be used. Please check with your

supplier for available protocols and compatible products.

Normal Fill Cycle

When the freezer is filled and the controller is operating, the

START FILL

and

LOW ALARM

sensors are

immersed in LN

2

. Their resistance values are interpreted by the controller as “in liquid”. At the same time, the

STOP FILL

and the

HIGH ALARM

sensors are above the liquid pool, informing the control that these sensors are

in vapor. As LN

2

evaporates, the liquid level in the freezer drops slowly until the

START FILL

sensor is above the

liquid and sends a different signal to the controller. After a delay sufficient to ensure the signal, the controller

interprets this condition as low liquid level and opens the solenoid valve, admitting more liquid nitrogen from

the supply source.

The freezer will fill slowly. The fill continues until the

STOP FILL

sensor sends the controller a signal that it is

now in liquid. The controller will close the solenoid valve to stop the fill. As liquid evaporates, the display will

indicate the liquid is at a normal level as the cycle begins again.

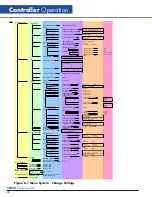

Control Setting Adjustments

Level

The standard sensor assembly that is installed on a freezer consists of a circuit board with thermistors installed.

The assembly has a maximum range of 6 in. (152 mm). Thermistor assignments can be changed through the

menu system and the operating range can be changed by either raising or lowering the thermistor sensor

assembly (offset) within the freezer.

Controller

Operation

Summary of Contents for CS200

Page 2: ......