CS200

Control Systems

38

1.

System Log:

System logs are events that occur in the system including lid opening/closing, LN

2

filling, Quick-

Chill and Defog.

2.

Error Log:

Error logs are outside the activated preset limits detected by the system.

3.

Temperature #1 Log and Temperature #2 Log (for use with optional thermocouple #2):

The two temperature

logs are simply records of the temperatures recorded by the thermocouples in the system.

All logs are kept in a non-volatile memory, meaning that the information is saved regardless of whether the

controller has power.

Display Brightness

DISPLAY BRIGHTNESS changes the intensity of the display. The default setting is 10.

Making Adjustments to the CS200 SERIES Control System Sensor Assembly

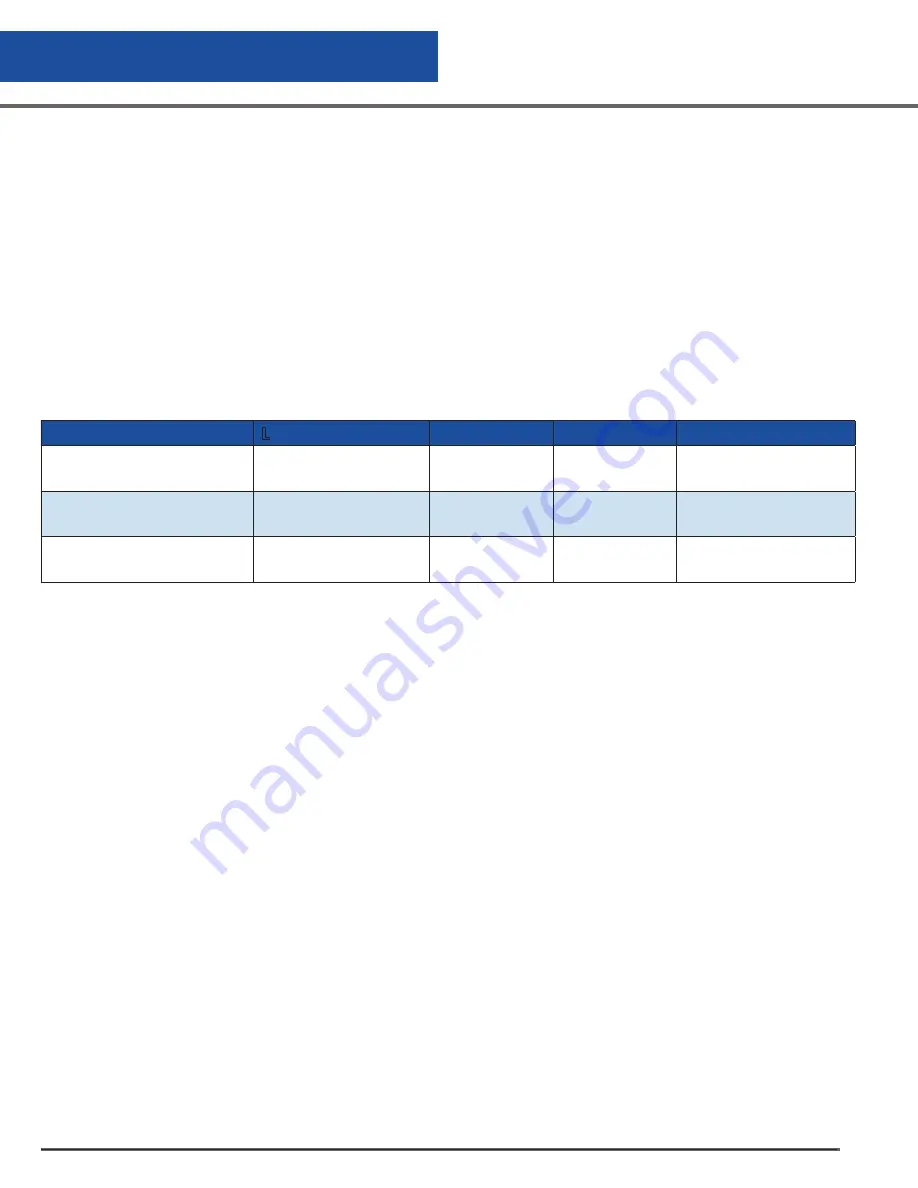

CRYOSTORAGE SYSTEM LOW LEVEL ALARM

START FILL

STOP FILL

HIGH LEVEL ALARM

LABS

20K, 38K, 40K, 80K

2 in. (50 mm)

3 in. (76 mm) 5 in. (127 mm)

(at carousel)

6 in. (152 mm)

LABS 94K

5 in. (127 mm)

6 in. (152 mm) 9 in. (228 mm)

(at carousel)

10 in. (254 mm)

K Series

10K, 24K, 38K

2 in. (50 mm)

3 in. (76 mm) 6 in. (152 mm)

6 in. (152 mm)

The sensor assembly is preset at the factory for vapor phase storage. If adjustments need to be made, the

following procedure will simplify the process.

The CS200 SERIES Control System control installed on the Worthington Industries Cryostorage units operates

with specially designed software to match the design characteristics of your freezer. Refer to the chart below to

see the versions and their difference.

To make adjustments to a sensor assembly in a freezer filled with LN

2

, the following procedure can be used:

• Measure the LN

2

in the freezer.

• Take this measured level and subtract the offset to determine how many sensors should be in

liquid.

a. Remove sensors.

b. Fill to correct level and turn off Liquid supply.

c. Eg. Level is to be 15 in. (381 mm) and sensor number 6 is currently and will remain the Stop

Fill. 15 in. (381 mm) – 6 in. (152 mm) = 9 in. (228 mm) offset. Set Offset to 9 in (228 mm).

• Go to “

Test Level Sensor

” through the CS200 SERIES Control System menu. “L” means a sensor is

in liquid and “G” means a sensor is in gas.

• Move the sensor up or down so that the appropriate numbers of sensors are in liquid (read “L”).

• Return to the CS200 SERIES Control System main screen and the level indicated should match the

physically measured reading.

The Sensor Offset

, the

START FILL

and the

STOP FILL

can be set through the CS200 SERIES Control System menu

system.

Controller

Operation

Table 9.0: CS200 SERIES Control System Sensor Assembly Factory Settings

Summary of Contents for CS200

Page 2: ......