Cordless hammer drill

EN

9

8

Waste electrical products must not

be disposed of with household

waste. Please recycle where

facilities exist. Check with your local

authorities or retailer for recycling

advice.

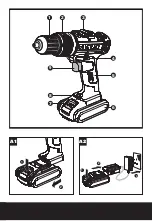

COMPONENT LIST

1. CHUCK

2. TORQUE ADJUSTMENT RING

3. TWO-SPEED GEAR CONTROL

4. FORWARD/REVERSE ROTATION CONTROL

5. SOFT GRIP HANDLE

6. BATTERY PACK *

7. BATTERY PACK RELEASE BUTTON *

8. SIGHT LIGHT

9. ON/OFF SWITCH

* Not all the accessories illustrated or de-

scribed are included in standard delivery.

TECHNICAL DATA

Type

WX371 WX371.1 WX371.2 WX371.3

WX371.4 WX371.5 WX371.6 WX371.7

WX371.9 WX371.10 (3-designation of

machinery, representative of hammer drill)

WX371 WX371.1

WX371.2 WX371.3

WX371.4 WX371.5

WX371.6 WX371.7

WX371.10

WX371.9

Charger voltage

100-240V ~50/60Hz

Rated voltage

20V Max**

No load speed

0-400/0-1500 min

Impact rate

0-6400/0-24000bpm

Number of clutch

position

18+1+1

Max torque

40N.m

Chuck capacity

13mm

Max.

drilling

capacity

Steel

13mm

Wood

30mm

Masonry

10mm

Machine weight

1.35kg

1.1kg

** Voltage measured without workload. Initial

battery voltage reaches maximum of 20 volts.

Nominal voltage is 18 volts.

NOISE INFORMATION

A weighted sound pressure

L

pA

: 76,4dB(A)

A weighted sound power

L

wA

: 87,4dB(A)

K

PA

& K

WA

3.0dB(A)

Wear ear protection.

VIBRATION INFORMATION

Vibration total values (triax vector sum) determined

according to EN 62841:

Impact drilling

into concrete

Vibration emission

value a

h,ID

= 4,8m/s²

Uncertainty K = 1,5m/s²

Drilling into metal

Vibration emission

value a

h,D

= 2,5m/s²

Uncertainty K = 1,5m/s²

The declared vibration total value and the declared

noise emission value have been measured in

accordance with a standard test method and may be

used for comparing one tool with another.

The declared vibration total value and the declared

noise emission value may also be used in a

preliminary assessment of exposure.

WARNING:

The vibration and noise emissions

during actual use of the power tool can differ

from the declared value depending on the ways in

which the tool is used especially what kind of

workpiece is processed dependant on the following

examples and other variations on how the tool is used:

How the tool is used and the materials being cut or

drilled.

The tool being in good condition and well maintained.

The use of the correct accessory for the tool and

ensuring it is sharp and in good condition.

The tightness of the grip on the handles and if any anti

vibration and noise accessories are used.

And the tool is being used as intended by its design

and these instructions.