11

Oscillating Tool

WX680

APPLICATION

WARNING: The sawing teeth are very sharp. Do not touch during mounting and

application.

The workpiece must be clamped tightly before it is cut.

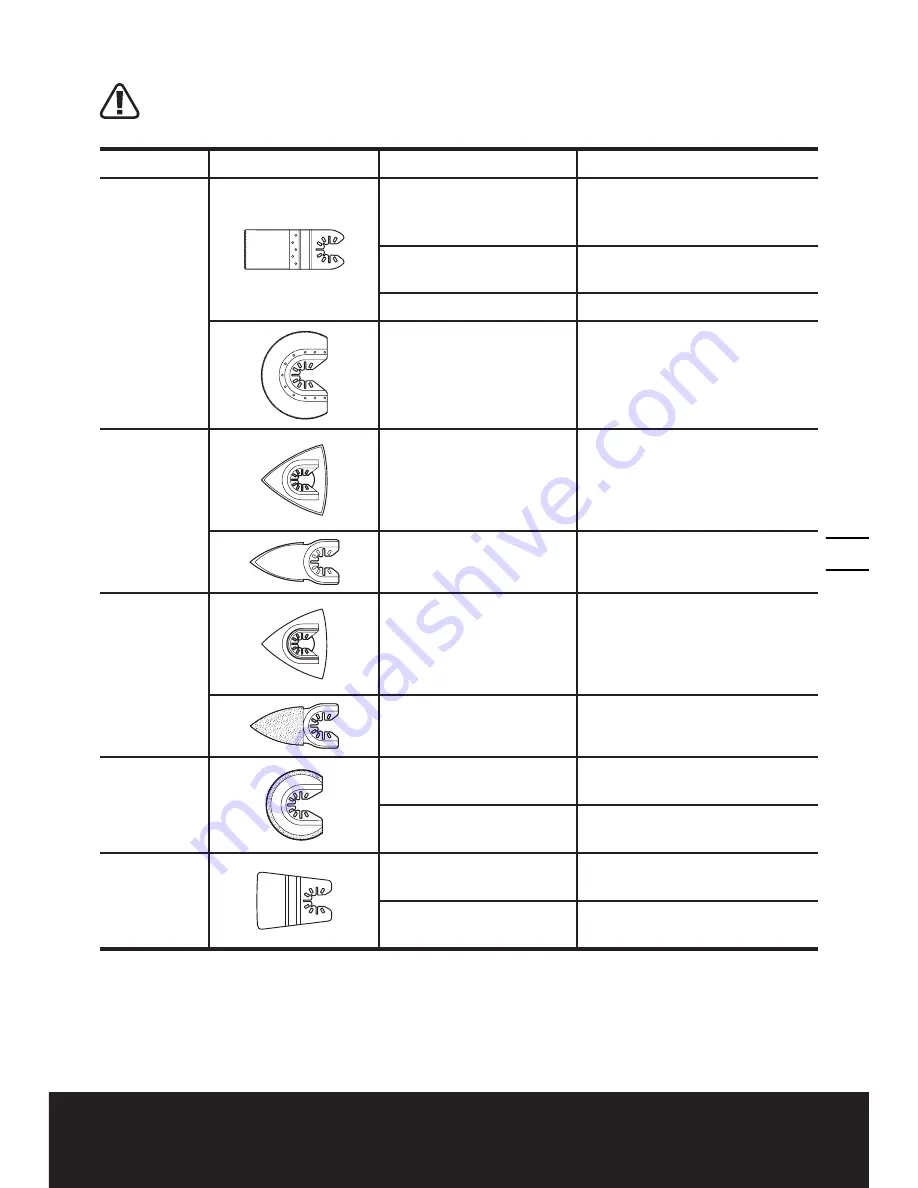

Pic

Description

Application

Sawing

Bi-Metal

Metal/Wood End Cut Blade

Wood, plastic, fiberglass,

nails, non-ferrous metals, thin

sheet metal, hardened fillers.

Standard Wood End

Cut Blade

Wood, plastic, drywall.

Precision Wood Cut Blade Wood, soft plastics.

HSS Semicircle Saw

Blade

Thin wood, plastic,

fiberglass,

non-ferrous metals, thin

sheet metal, hardened fillers,

window glazing.

Sanding

Sanding Pad

(Perforated)

Wood, plastic, hardened

fillers.

Sanding Finger Pad

Wood, plastic, hardened

fillers.

Rasping

Triangular Carbide Grit

Rasp

Wood, hardened adhesives,

thin set, masonry.

Carbide Rasp (Finger

Shaped)

Wood, hardened adhesives,

thin set, masonry.

Removing

grout

Carbide Grit Semicircle

Saw Blade

Grout, porous concrete,

masonry.

Diamond-Coated

Semicircle Saw Blade

Ceramic and stone tile,

backerboard.

Scraping

Rigid Scraper Blade

Old paint, hardened

adhesives, caulk, carpet.

Flexible Scraper Blade

Elastic sealants, paint,

adhesive residues, carpet.

NOTE:

When plunging and sawing use a slight pendulum motion, to allow sufficient chip

removal.The saw blade lasts longer if the wear is distributed evenly. To ensure an even

distribution, loosen the saw blade, rotate it and retighten firmly.Cut/Sand with a constant

movement and light pressure. Heavy pressure does not increase the cut/removal rate – the

accessory merely wears faster.