Circular Saw WT430K

13

12

The angle markings on the angle scale (17) are accurate

for most general purposes but it is recommended, for

accurate work, to set the angle with a protractor and

make a test cut on other material. Do not use the depth

of cut scale (10) when making bevel cuts due to pos-

sible inaccuracy.

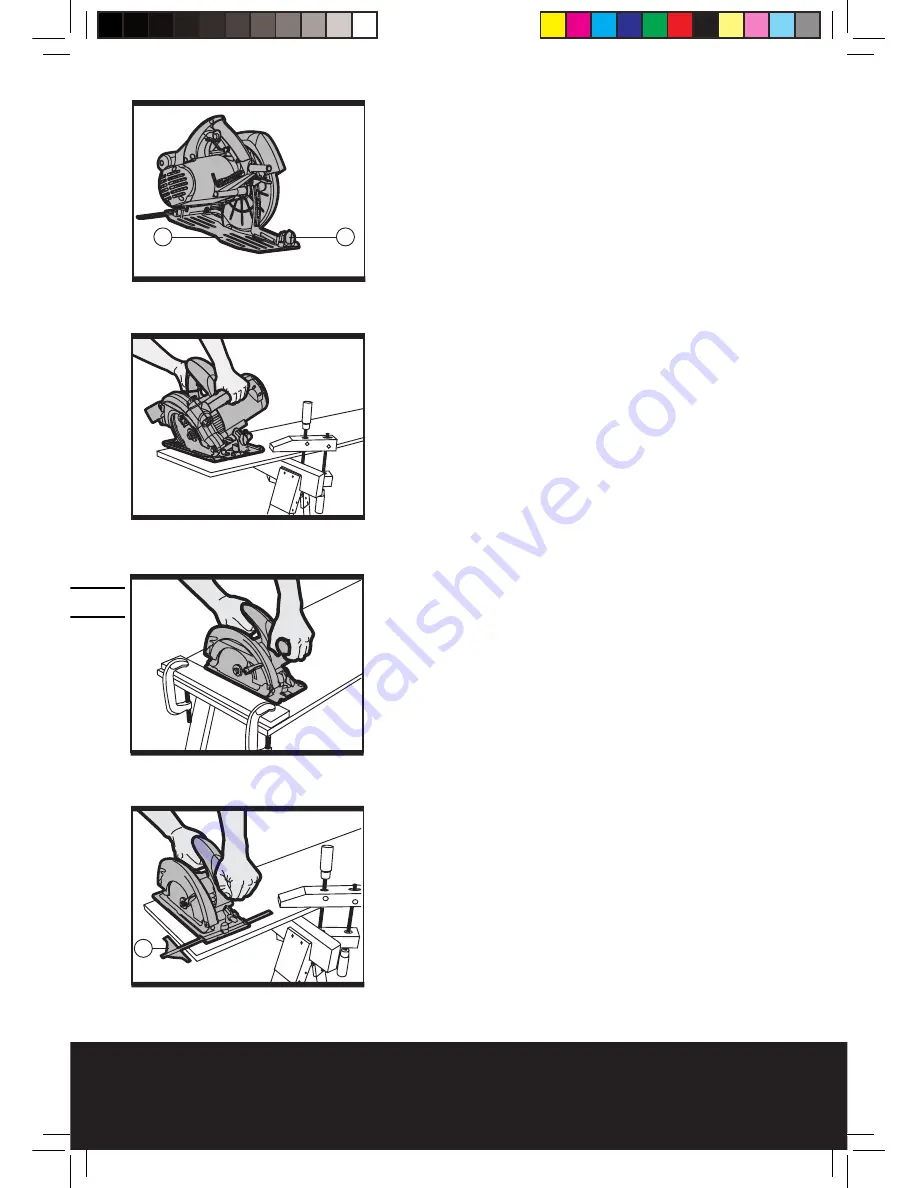

7. CUTTING GUIDE

There is a cutting guide notch (18) on the front of the

base plate (3) for use with a parallel guide (20). For

straight cuts, use the 0º guide mark to align with your

parallel guide scale. For a 45º bevel cut, use the 45º

guide mark to align with your parallel guide scale (See

Fig 6 and 7). Securely clamp the parallel guide (20). Al-

ways make a trial cut to check the setting.

8. PARALLEL GUIDE ADJUSTMENT

The parallel guide is used for making cuts parallel to a

work-piece edge at a chosen distance. Slide the parallel

guide (21) arm through both fixtures (19) to achieve the

required cutting distance and tighten screw to lock into

position (See Fig 8). It can be used from both sides of

the base plate (3). The cutting distance is shown on the

guide scale and by using the 90º or 45º notch edge (18)

on the base plate (3). Always make a trial cut to check

the setting.

9. DUST EXTRACTION OUTLET

To remove sawdust, connect a suitable external dust

extraction device (e.g. vacuum cleaner) to the dust ex-

traction outlet (12) using the adapter (19) and a flexible

hose connection. Ensure the hose connection is secure

(See Fig 9).

WORKING HINTS FOR YOUR CIR-

CULAR SAW

a) If your power tool becomes too hot, run your circular

saw no load for 2-3 minutes to cool the motor. Avoid

prolonged usage at very low speeds.

b) Always use a blade suited to the material and mate-

rial thickness to be cut. The quality of cut will improve

as the number of blade teeth increase.

c) Always ensure the work-piece is firmly held or

clamped to prevent movement. Support large panels

close to the cut line. Any movement of the material

may affect the quality of the cut. The blade cuts on the

upward stroke and may chip the uppermost surface or

edges of your work piece. When cutting, ensure your

uppermost surface is a non-visible surface when your

20

Fig 8

Fig 7

Fig 6

7

3

Fig 5

NA-WT430K B37-M-050929.indd 12

2005-9-29 11:53:05