Cordless rotary hammer

WX382 WX382.1

WX382.2 WX382.3 WX382.4

11

D

C

2

1

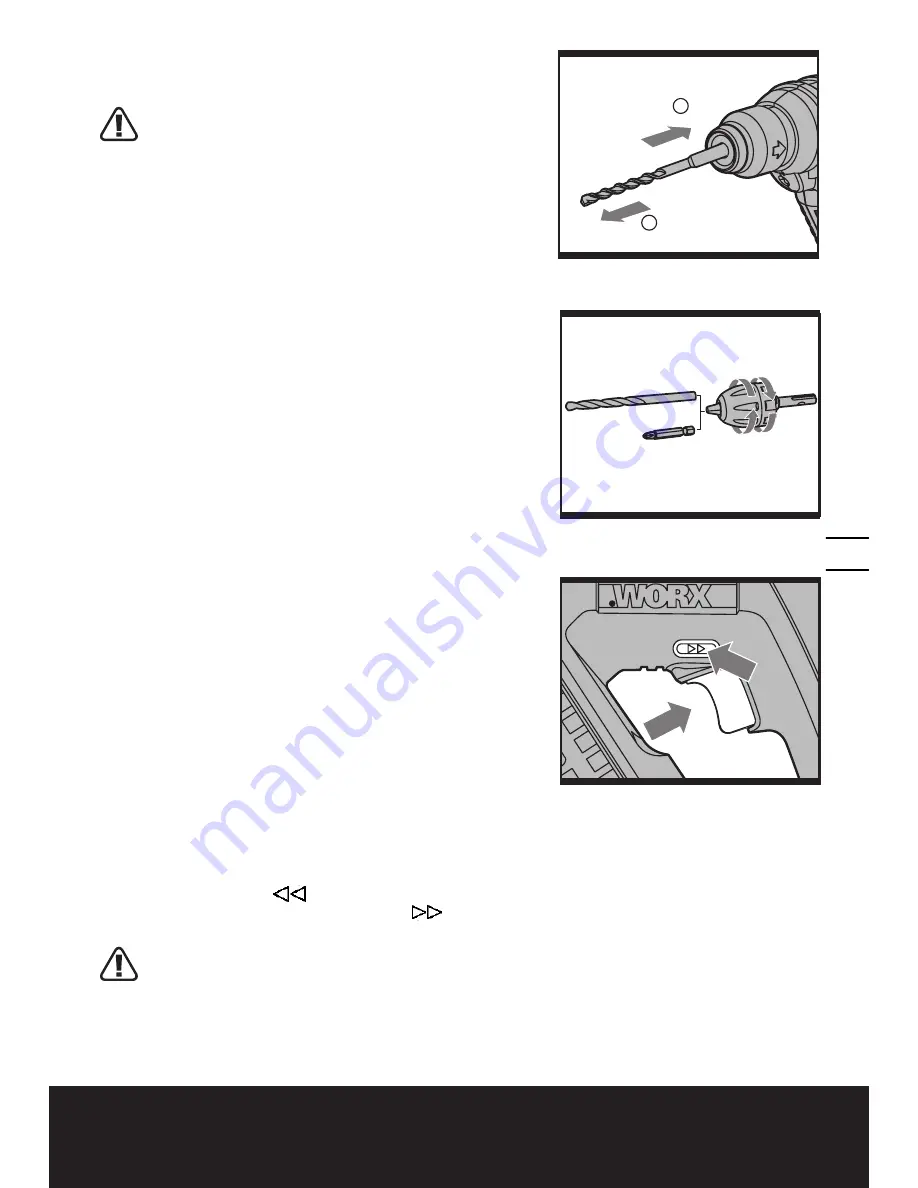

— REMovING (See Fig. B3)

Retract back the bit holder locking sleeve (2) and pull

out the bit.

WARNING:

Your new WORX Rotary Hammer

Drill generates powerful forces to get your job

done quickly and effectively. These forces may cause

inferior quality SDS bits to break and jam in the chuck,

We therefore recommend that only high quality SDS

bits be used with this tool.

2. INSERtING A tool INto CHUCK (13) (See

Fig. C)

To open the chuck jaws rotate the front section of the

chuck while holding the rear section. Insert the drill bit

between the chuck jaws and rotate the front section in

the opposite direction while holding the rear section.

Ensure that the drill bit is in the center of the chuck

jaws. Finally, firmly rotate the two separate chuck

sections in opposite directions. Your drill bit is now

locked in the chuck.

3. oN/oFF SWItCH (See Fig. D)

Depress the On/Off switch (4) to start and release it to

stop your tool.

— oN/oFF SWItCH WItH vARIABlE SPEED

CoNtRol

Depress the On/Off switch to start and release it to stop

your tool. This tool has a variable speed switch (4) that

delivers higher speeds with increased trigger pressure

- speed is controlled by varying the pressure applied to

the switch.

4. SWItCH loCK (See Fig. D)

The switch trigger can be locked in the OFF position.

This helps to reduce the possibility of accidental

starting when not in use. To lock the switch trigger,

place the direction of rotation control in the center

position.

5. FoRWARD AND REvERSE RotAtIoN CoNtRol

(See Fig. D)

With the hammer pointing away from you, push the

forward/reverse-lever “

“ to the left for forward

rotation. Push the forward/reverse-lever “

“ to the

right for reverse rotation.

WARNING:

Never change the direction of

rotation while the tool is rotating, wait until

it has stopped.

B3