Rev 6.0/11-20

FL1-DC: #35026

7

1) Remove all shipping materials and save them with the shipping container for future use.

2) Suspend the lifter from appropriate hoisting equipment:

2.1) Select a crane and/or hoist rated for the Maximum Load Capacity plus the

Lifter Weight.

Note: Any lifter use must comply with all statutory or regulatory standards for hoisting

equipment in your region.

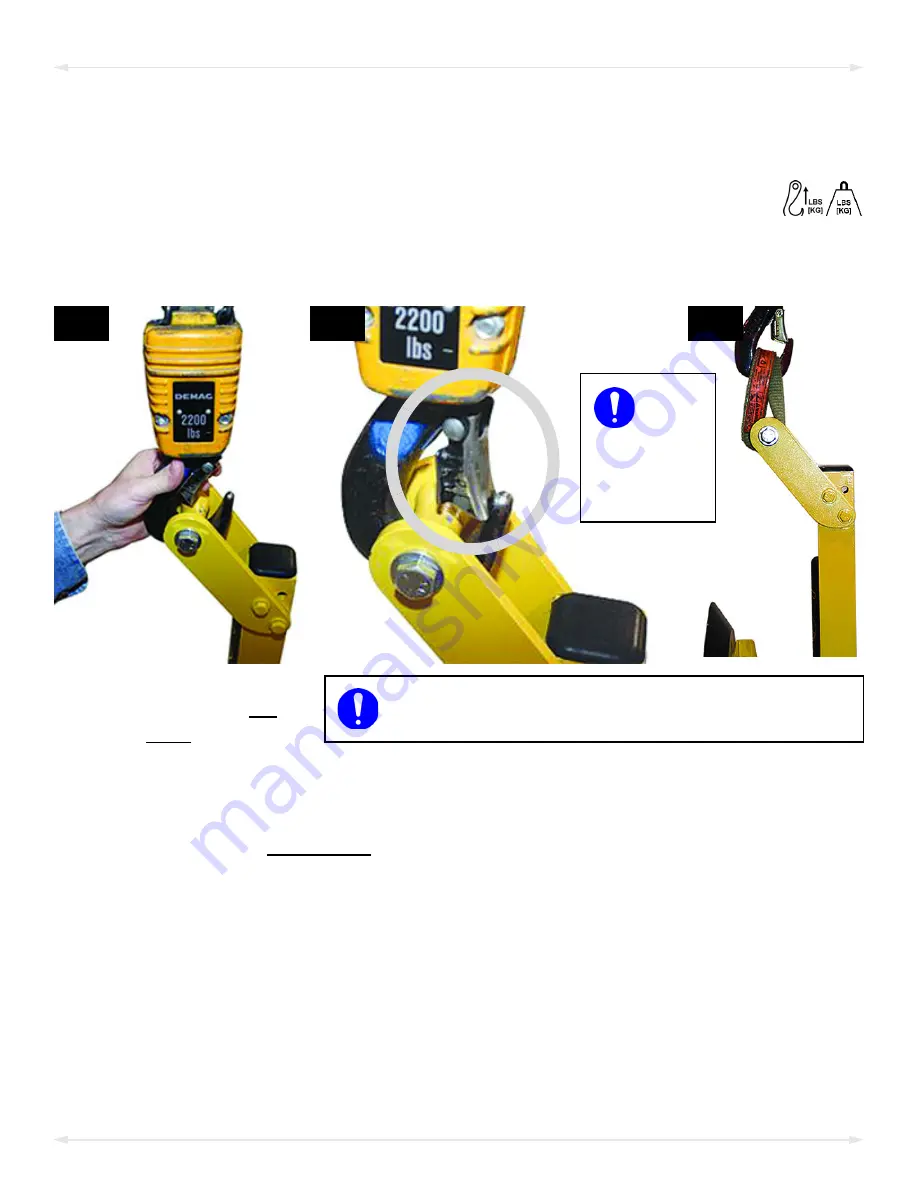

2A

2B

2C

Make

sure

hook has

restraining

latch

(circled).

2.2)

Only use rigging rated for Maximum Load Capacity

plus Lifter Weight.

Attach the hoisting

hook to the lift

point (figs. 2A-B).

Use rigging as

needed (fig. 2C) to make sure the hook does not interfere with the load.

2.3) Use the hoisting equipment to remove the lifter from the shipping container. Avoid

damaging the vacuum pad.

ASSEMBLY