Rev 1.0/2-17

4

#35204

OPERATION

A

BOUT THE

T

ILT

L

OCK

Although the tilt linkage normally holds a balanced load in position, the Tilt Lock can be used to

prevent tilt motion due to wind loads or other unexpected forces. The Tilt Lock should only be

needed if the operator cannot maintain control of the load using the control handle or other

appropriate means (such as when using the lifter to install glass in multi-story buildings). The

Tilt Lock is a secondary safety device and does not eliminate the need to load the lifter correctly

(see OPERATION: T

O

A

PPLY THE

P

ADS TO A

L

OAD

in MRTA8 lifter's instruction manual).

Caution: Failure to load lifter correctly may damage Tilt Lock or other lifter

components.

The Tilt Lock can be set to engage automatically when the pad frame reaches the vertical or

horizontal position, or it can be deactivated, depending on the application.

T

O

U

SE THE

T

ILT

L

OCK

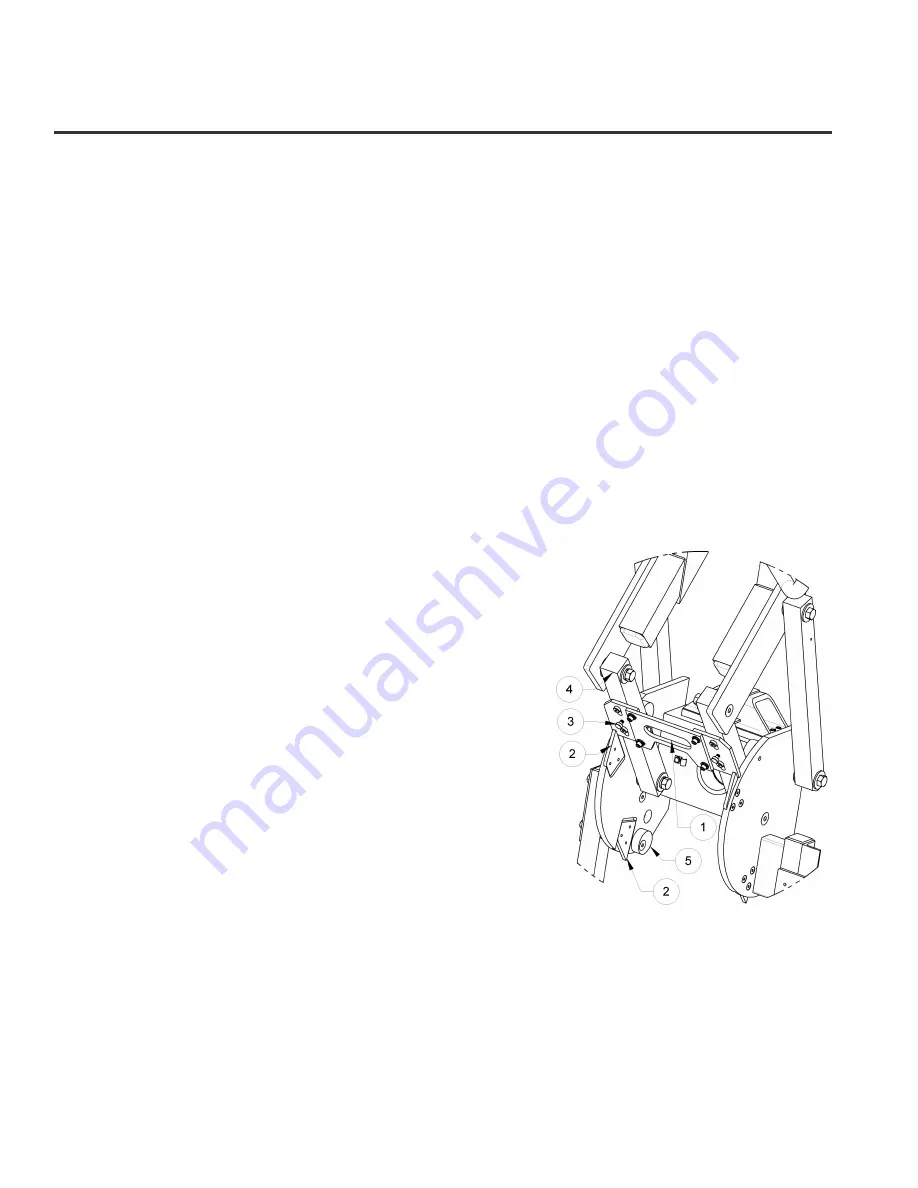

To allow automatic locking, make sure the lock handle/catch plate

assembly (#1) is set to slide up and lock behind the lock ramp plates

(#2) when the pad frame moves to either the vertical or horizontal

position. If not, pull outward on the round knobs of the two

spring plungers (#3) and turn them 90° to release the

handle/catch plate assembly. Make sure that the catch plates

slide freely along the bars of the tilt linkage (#4) before you

attempt to tilt the pad frame. If the catch plates do not lock

behind the ramp plates or if the pad frame exhibits excessive

play in either the vertical or the horizontal orientation, the

stop cams (#5) for the tilt linkage may require adjustment

(see INSTALLATION step 7). Once the Tilt Lock is set to the

automatic mode, simply pull on the lock handle to disengage

the lock.

T

O

D

EACTIVATE THE

T

ILT

L

OCK

Make sure the lock handle/catch plate assembly (#1) is

secured so that it

cannot lock behind the ramp plates (#2). If

otherwise, turn the round knobs of the spring plungers (#3)

90° and then slide the lock handle/catch plate assembly

upward until the spring plungers engage. Make sure that the

catch plates do not slide along the bars of the tilt linkage (#4).

1) LOCK HANDLE/CATCH PLATES

2) LOCK RAMP PLATE

3) SPRING PLUNGER

4) TILT LINKAGE

5) TILT STOP CAM