Rev 8.0/1-20

MRTALP8-DC3: #35059

31

INSPECTIONS AND TESTS

I

NSPECTION

S

CHEDULE

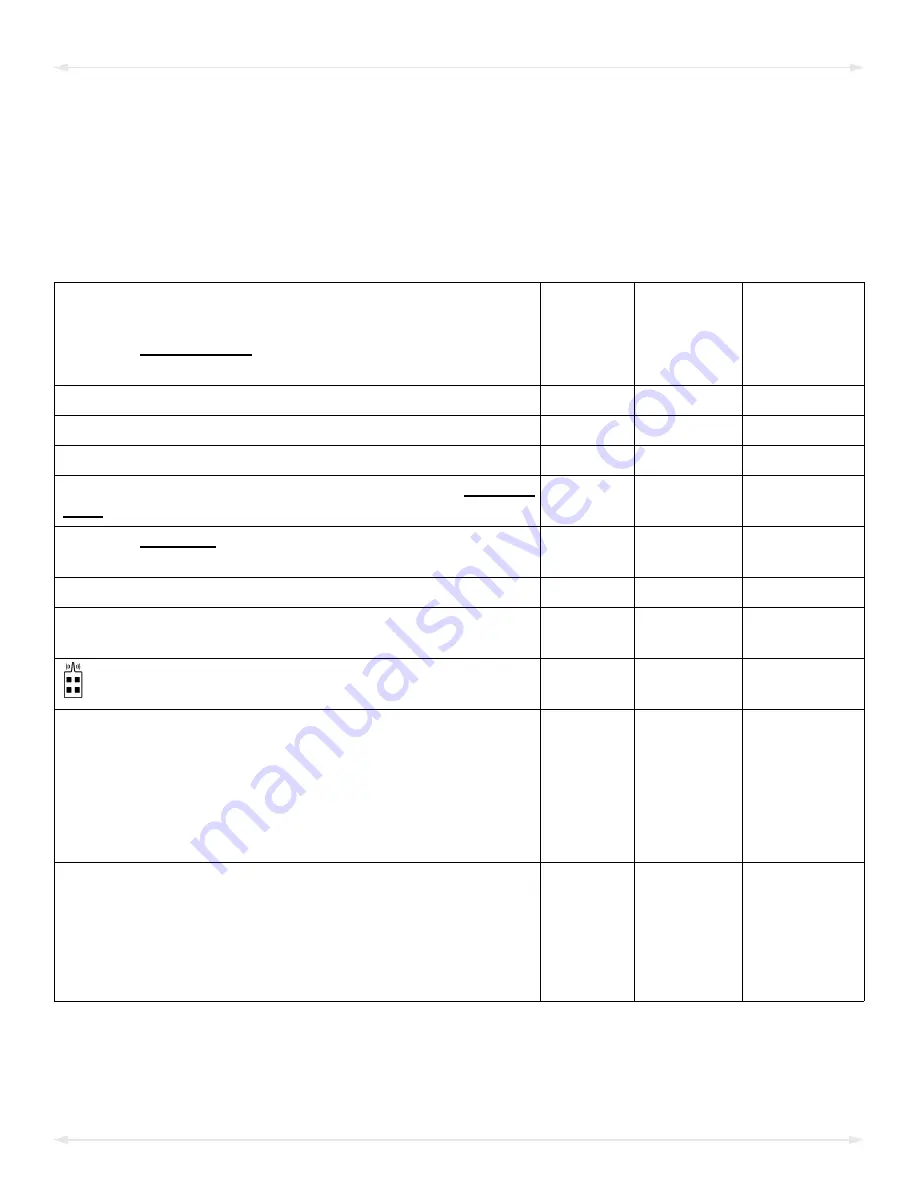

Perform inspections according to the following frequency schedule. If any fault is found, correct

it and perform the next most frequent inspection before using the vacuum lifter.

Action

Every Lift Frequent

1

1...... The Frequent Inspection is also required whenever the lifter has been out of service for 1 month or more.

(Every 20-40 hrs.)

Examine vacuum pads for contaminates or damage

(see “Pad Inspection” on page 35).

Examine load surface for contaminates or debris.

Examine controls and indicators for damage.

Examine lifter’s structure for damage.

Examine vacuum system for damage (including vacuum

pads, fittings and hoses).

Examine air filters for conditions requiring service (see

“A

IR

F

ILTER

M

AINTENANCE

” in

SERVICE MANUAL

).

Perform “Vacuum Test” on page 33.

Check for unusual vibrations or noises while operating

lifter.

If lifter has Remote Control System, perform

“Remote Control System Test” on page 34.

Examine entire lifter for evidence of:

• looseness, excessive wear or excessive corrosion

• deformation, cracks, dents to structural or functional

components

• cuts in vacuum pads or hoses

• any other hazardous conditions

Inspect entire electrical system for damage, wear or

contamination that could be hazardous, in compliance

with all local codes and regulatory standards.

Caution:

Use appropriate cleaning methods for each

electrical part, as specified by codes and standards.

Improper cleaning can damage parts.

Note: If a lifter is used less than 1 day in a 2-week period, perform the Periodic Inspection before

using it.

Periodic

2

(Every 250-400 hrs.)

2...... The Periodic Inspection is also required whenever the lifter has been out of service for 1 year or more. Keep a written record of all Periodic Inspections. If

necessary, return the lifter to WPG or an authorized dealer for repair (see “LIMITED WARRANTY” on page 44).

Summary of Contents for MRTALP810CDC3O

Page 2: ...MRTALP8 DC3 35059 Rev 8 0 1 20 2 ...

Page 6: ...MRTALP8 DC3 35059 Rev 8 0 1 20 4 Note A standard MRTALP811LDC3 is shown SPECIFICATIONS ...

Page 11: ...Rev 8 0 1 20 MRTALP8 DC3 35059 9 TO CHANGE THE PAD FRAME CONFIGURATION ASSEMBLY ...

Page 47: ...Rev 8 0 1 20 MRTALP8 DC3 35059 45 ...

Page 48: ...MRTALP8 DC3 35059 Rev 8 0 1 20 46 ...

Page 49: ......

Page 50: ......