Rev 8.0/1-20

MRTALP8-DC3: #35059

35

MAINTENANCE

Replace any pad that has damaged

sealing edges.

Notes: Refer to

SERVICE MANUAL #36105

when applicable. See final section for wiring

diagrams.

V

ACUUM

P

AD

M

AINTENANCE

Pad-to-Load Friction Coefficient

The friction coefficient represents the lifter's ability to resist load slippage.

1

The Maximum

Load Capacity is based on a friction coefficient of 1, as determined by testing of clean,

new, standard rubber vacuum pads on clean, dry, regular glass.

If the lifter is used under other

conditions, a qualified person

must first determine the effective lifting capacity.

2

Long-term exposure to heat, chemicals or UV light can reduce the friction coefficient of vacuum

pads. Replace pads every 2 years or more often, when necessary.

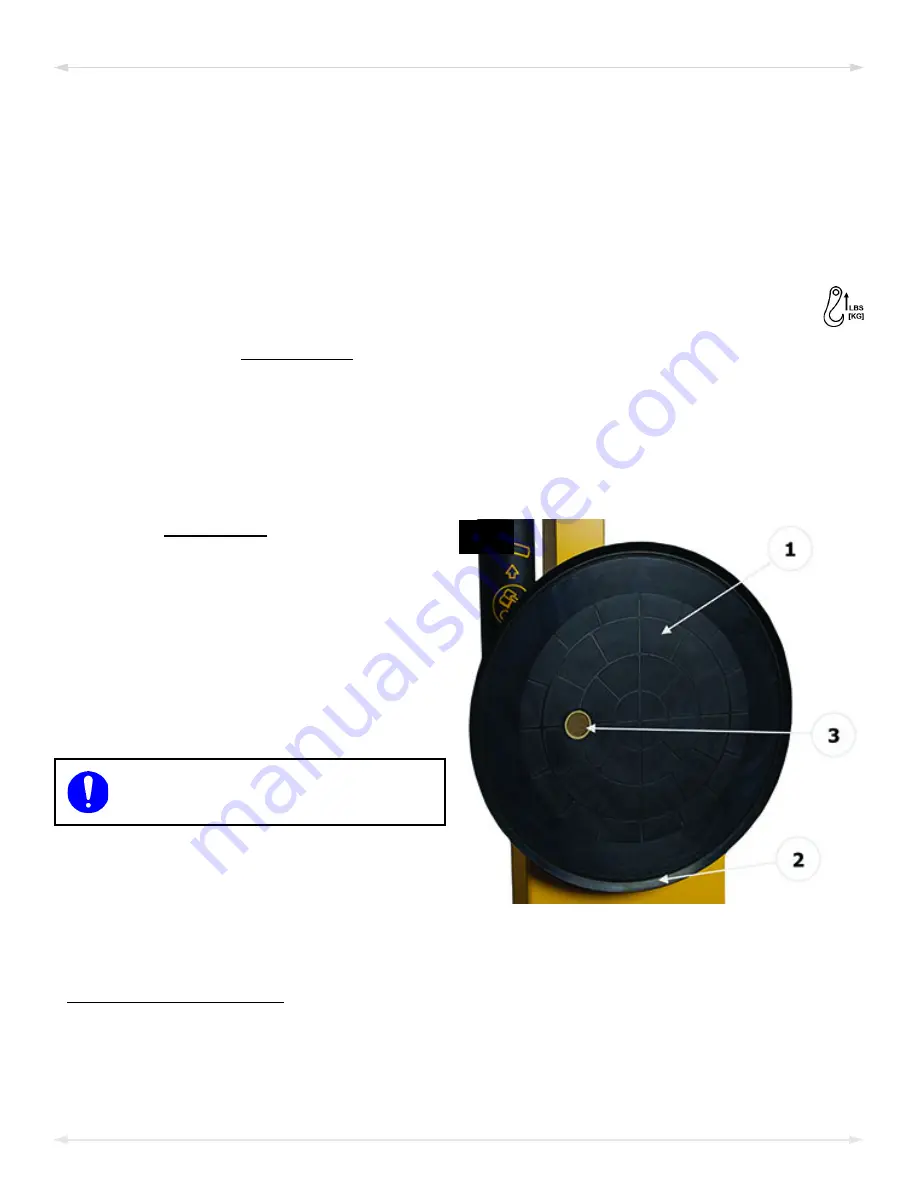

Pad Inspection

1A

Inspect each vacuum pad (fig. 1A) according to

the “I

” on page 31, and

correct the following faults before using the

lifter (see “REPLACEMENT PARTS”, when

applicable):

• Contaminates on the face (1) or sealing

edges (2).

• Filter screen (3) missing from face.

• Nicks, cuts or abrasions in sealing edges.

• Wear, stiffness or glaze.

1..... Not applicable to Flat Lifters.

2..... A “qualified person” has successfully demonstrated the ability to solve problems relating to the subject matter and work, either by possessing a

recognized degree in an applicable field or a certificate of professional standing, or by possessing extensive knowledge, training and experience.

Summary of Contents for MRTALP810CDC3O

Page 2: ...MRTALP8 DC3 35059 Rev 8 0 1 20 2 ...

Page 6: ...MRTALP8 DC3 35059 Rev 8 0 1 20 4 Note A standard MRTALP811LDC3 is shown SPECIFICATIONS ...

Page 11: ...Rev 8 0 1 20 MRTALP8 DC3 35059 9 TO CHANGE THE PAD FRAME CONFIGURATION ASSEMBLY ...

Page 47: ...Rev 8 0 1 20 MRTALP8 DC3 35059 45 ...

Page 48: ...MRTALP8 DC3 35059 Rev 8 0 1 20 46 ...

Page 49: ......

Page 50: ......