Always check battery

energy before every lift.

P1-DC3: #35123AUS

Rev 4.0/2-21

12

Performing Inspections and Tests

• Follow the

.

•

Examine air filters regularly

and service when needed.

Service the 2 air filters whenever a bowl contains

liquid or other contaminates, or an element

appears dirty (see “A

IR

F

ILTER

M

AINTENANCE

” in

).

•

Make sure

notification

buzzer can be

heard over noise

at operator

position.

Make sure the notification buzzer is clearly

audible at the maximum distance between the

operator and the lifter, despite any barriers or

obstacles.

1,

2

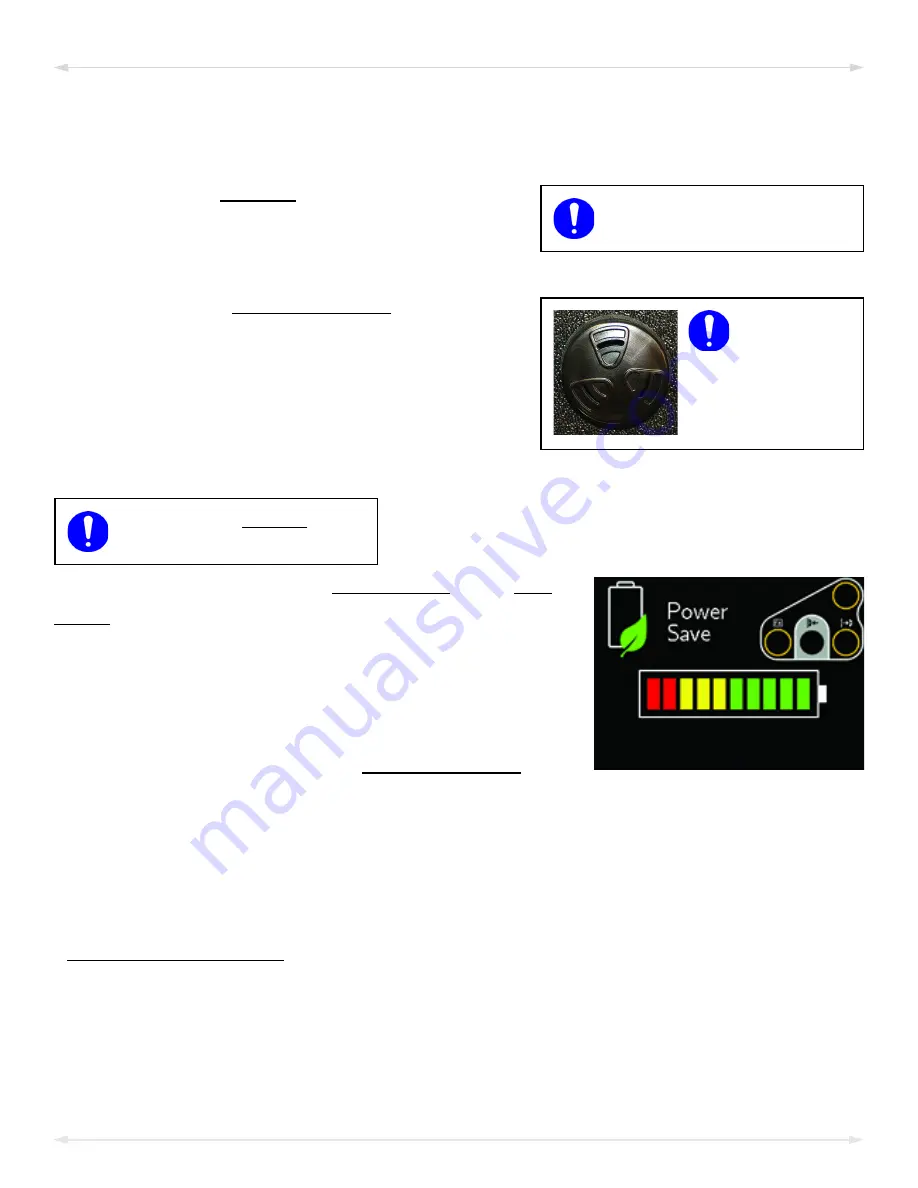

Checking the 12-Volt Battery

While the lifter is powered up, a battery gauge on the LCD

screen displays the current energy level.

3, 4

• If battery energy is in the red range, discontinue lifter

use and charge the battery (see

).

• If battery energy continues to decrease and you try to

attach the lifter to a load, the notification buzzer will

sound continuously and the LCD screen will display “Lockout (low 12V battery)”, along

with a diagnostic code (see

). In this case, you must

charge the battery in order to continue using the lifter.

1..... Maximum buzzer volume is 95 dBA at 2' [60 cm].

2..... The

provides a convenient opportunity to check this.

3..... If the lifter remains in “Power Save” mode for a long time, the pump will run periodically to test the battery.

4..... If the battery charger is connected to an AC power source, the reading on the battery gauge will not be accurate and “Replace 12V battery?”

may appear on the LCD screen, because the system cannot accurately evaluate the battery.

OPERATION