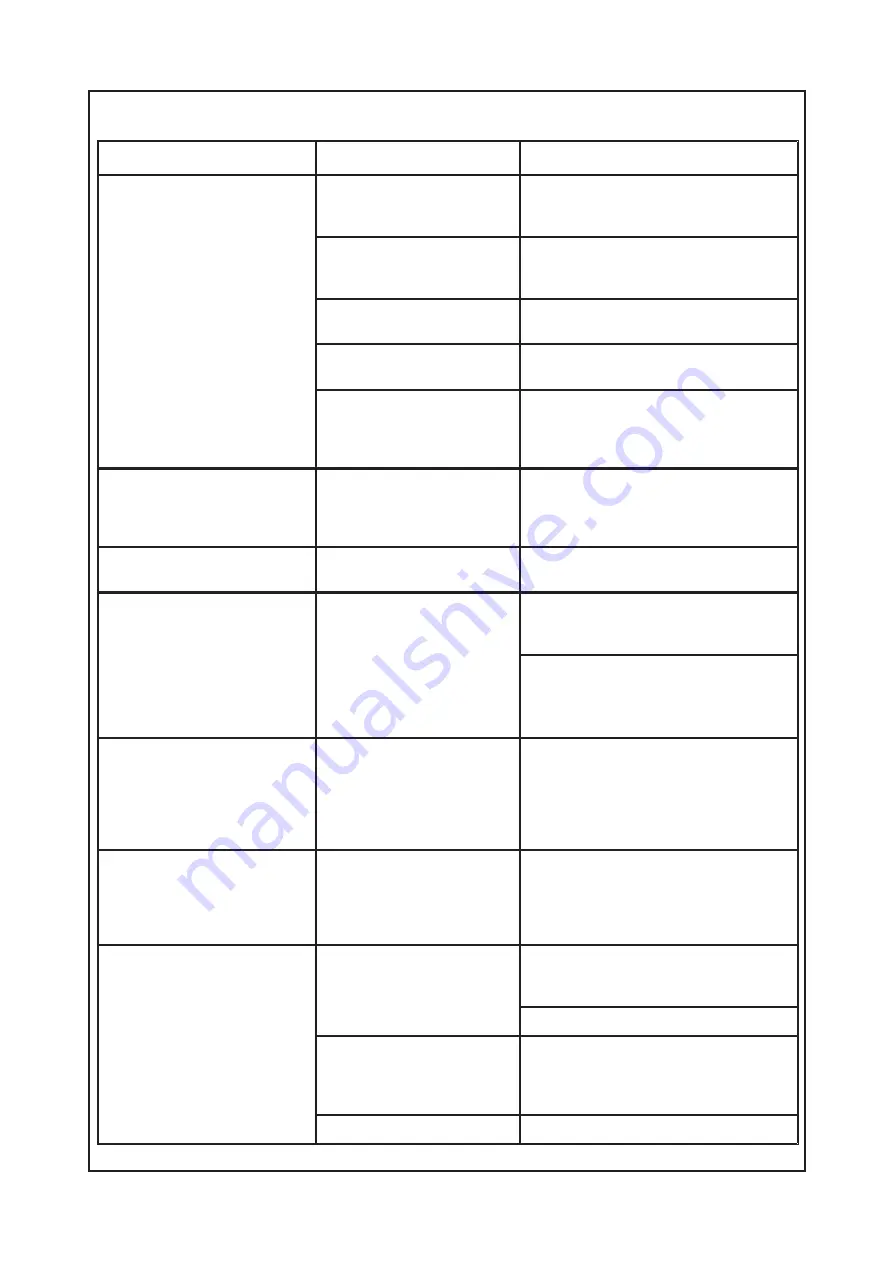

4. TROUBLESHOOTING AND PROBLEM SOLVING

4.1 DMS/DMC Models

A - SYMPTOM

B - CAUSE

C - REMEDIAL ACTION

1. Air blower is running

but little or no turbulence

is observed in aeration

chamber

This could be due to

insu

ffi

cient air supply to

the aeration chamber,

caused by one or more of

the reasons opposite:

1. Blocked air di

ff

user

1. Disconnect air pipe at the

union and clean or replace air

di

ff

user

2. Blocked air hose or

pipe

2. Inspect hose and pipe for

blockages, especially at joints.

Unblock as necessary

3. Leaking hose or pipe

joints

3. Inspect all hose and pipe joints

and tighten as necessary

4. Kinked, crushed or

split air hose or pipe

4. Inspect and replace as

necessary

5. Excessively worn

carbon vanes in Rotary

Vaned Air Pump (DMC

only)

5. See speci

fi

c air blower manual

2. Aeration chamber

contents have

a greyish (dishwater)

appearance

6. As B 1-4

6. As C 1-5

3. Noticeable odour &

poor e

ffl

uent quality

7. As B 1-4

7. As C 1-5

4. Aeration chamber

contents are grey/brown

to black. Slight to strong

septic odour. E

ffl

uent

quality is poor and is grey.

Air blower is running

and good turbulence is

evident

8. Heavy hydraulic surge

fl

ows from laundry or

kitchen activities

8. For commercial applications,

install a surge tank before the

Diamond

9. For residential applications,

reduce the

frequency of laundry to 1-2 loads

per day

5. Aeration chamber has

a clear appearance

with very few suspended

solids (<5%). White suds

observed. E

ffl

uent is clear

with no odour

9. Light loading

resulting in total

digestion of solids

10. No action required if e

ffl

uent

quality is acceptable. Typical of

intermittent use.

6. Aeration chamber as 5,

but with very

fi

ne

particles in the e

ffl

uent

causing it to appear

turbid or murky

10. See B 8

11. See C 8-9

7. Aeration chamber

contents have a

grey appearance and

slightly septic odour

11. System is lightly

loaded and has been

in use for less than 3

months

12. Continue start-up regime of

minimal laundry and minimal

cleaning chemicals.

13. See C 1-5

12. Insu

ffi

cient organic

matter present in the

in

fl

uent resulting in a

slow start-up

14. “Seed” plant with WPL

Formula 33 to help initiate start-

up

13. See B 8

15. See C 10

13