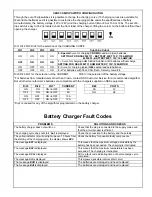

Battery Charger Operating Instructions - SPE

GENERAL INFORMATION AND WARNINGS

NSS machines are delivered with the SPE charger

set to Curve #0 for Crown batteries.

Electronic automatic battery charger with

microprocessor suitable for any battery type.

Fully automatic charging cycle with electronic

setting; protected against overload, short-circuit at

clamps and reversed polarity.

Before starting to charge, make sure the voltage of

the equipment suits the voltage of the battery, that

the charging current suits the capacity of the

battery and that the selected charging curve (for

lead-acid batteries or airtight gel batteries) is

correct for the type of battery to be charged. In

addition, make sure the rated input voltage of the

charger suits the available supply voltage and the

system is equipped with grounding.

Pay attention to any remarks of the battery

manufacturer.

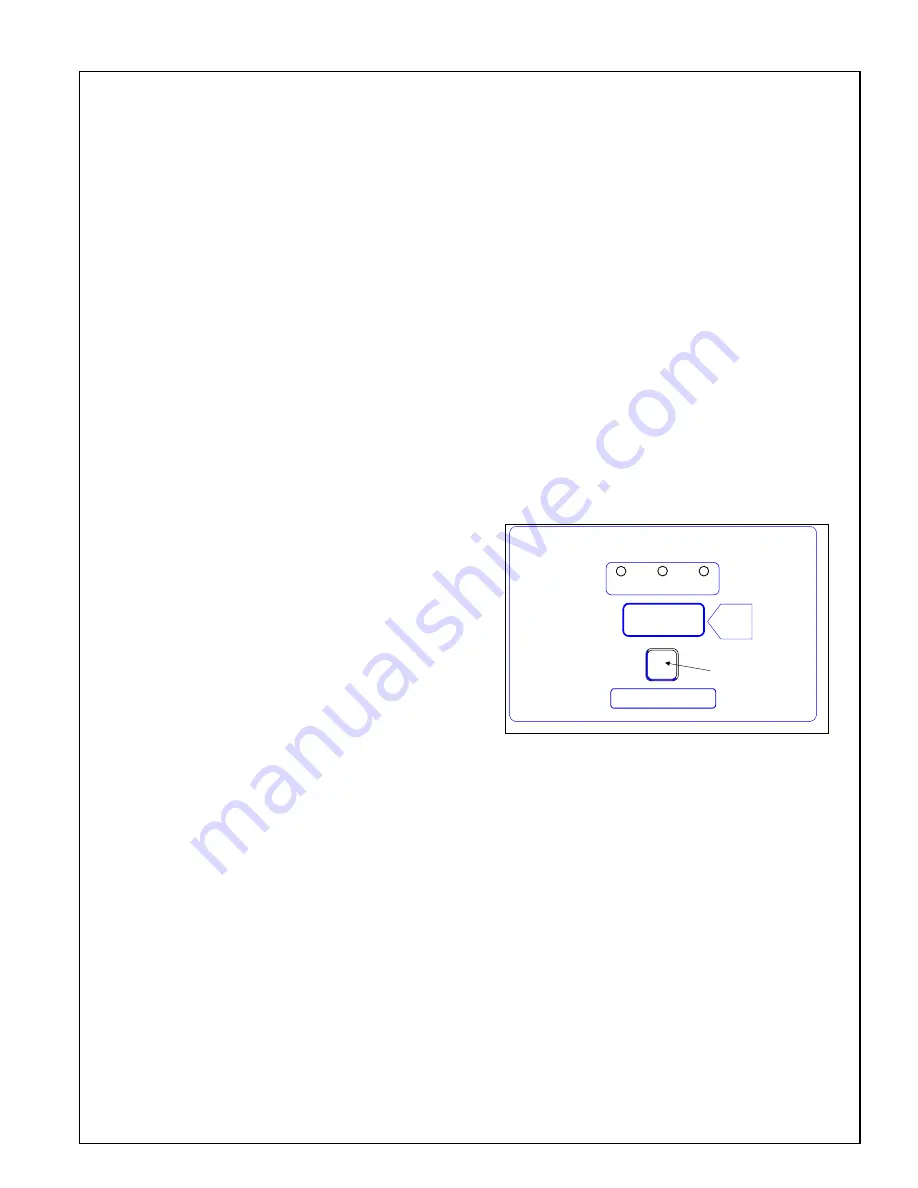

CONTROLS (see figure below)

1. Three-digit d symbol (1), to view

A

= the

charging current,

U

= the battery voltage,

h

= the

charging time,

C

= the charging ampere-hours

[Ah],

E

= the energy used [KWh].

2. Button for the

S

election of the display mode

(2):

A, U, h, C, E

. After about 10 seconds the

display returns to the visualization of the charging

current.

3. Red control indicator (3): when it is on, the

charging cycle has started.

4. Yellow control indicator (4): when it is on, the final

phase of the charging cycle has started.

5.

Green control indicator (5): when it is on, the

charging cycle has finished.

OPERATION INSTRUCTIONS

Plug the cord into a socket.

Now, the battery charger’s display will show a

sequence of details on the charger’s internal

programming: after the name “SPE”, it will show

the software release installed in the equipment,

then, in sequence, the following parameters:

battery voltage, charging current, charging curve

number and, finally, the words

“GEL”

or “

Acd

”

depending on the set up charging curve being

suitable for airtight gel batteries or lead-acid

batteries. Now, a test is run on the battery voltage

to decide if the charging process should be started

or not. If the battery is not connected to the battery

charger, the display will show the word

“bat”

. The

word will stay on, even if the test is failed (for

instance, reversed polarities or incorrect battery

connection). If the test is passed, the display will

show the battery voltage for approximately 5

seconds and the battery will begin to be charged.

The charging cycle progress will be shown by red

(3), yellow (4) and green (5) LED indicators. At the

end of the charge, when the green indicator (5) is

on, unplug the cord from the socket and operate

the machine.

SMART BATTERY CHARGER

MOD. CBHF1-SM 24V 12A

S

A = Amps

U = Volts

h = hours

C = Ah

E = KWh

1

2

3

4

5

F

RONT

P

ANEL OF

B

ATTERY

C

HARGER MODEL

CBHF1-SM

Summary of Contents for 2016 AB

Page 14: ...EC DECLARATION OF CONFORMITY...

Page 15: ...NOTES...