charging, add only enough water to cover the top of

the internal plates. After charging, add only enough

water to bring the level to the bottom of the fill tube.

Do not

overfill the battery liquid, this will cause

electrolyte (acid) spill. Spilled electrolyte (acid) can

cause machine damage and personal injury. Clean

and dispose of spills immediately.

Every cell

of every battery must be checked and

replenished (if needed) once per week

See the battery-warning sheet (page 2) for more

details.

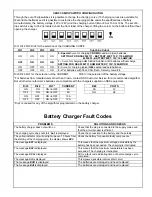

Battery Packages

The Wrangler 2016 is a 24-volt system and is available

with two battery packages.

Four (4) 6 volt, 235 Amp Hour Batteries – NSS-PCS.

Two (2) 12 volt, 145 Amp Hour Batteries - SPE.

Solution and Recovery Tanks

The recovery tank is emptied through a large rubber

hose at the front of the machine. Remove the plug

and drain the liquids according to your local and

federal regulations.

Every time

you empty the recovery tank, we

recommend that you add at least 4 to 6 ounces of

defoamer chemical into the recovery tank before

resuming work. Vacuum the defoamer into the empty

recovery tank through the squeegee vac hose.

At the end of the day empty all liquids from both

solution and recovery tanks. Rinse both tanks with

clean water to prevent chemical residue build-up,

allow to air - dry to prevent odors.

Remove any residue from screen and float ball to

ensure proper operation. Replace float assembly in

recovery tank.

Check clear lid for airtight seal.

Check the drain hose for damage.

Inspect and clean the vac filter located under the top

metal plate. Every 50 hours.

Pad driver or brush

Remove either pad driver or brush from the machine

after use.

Rinse with clean water to prevent chemical residue

build-up.

Allow to air dry on a peg or upside down on a shelf or

rack.

Inspect for wear or damage. Repair or replace as

needed.

Squeegee Assembly

Remove squeegee assembly from machine.

Rinse with clean water to prevent chemical residue

build-up. ***NOTE: prolonged exposure to some wax

stripper brands may degrade the squeegee material.

Rinsing after use in a wax floor stripping application is

highly recommended.

Allow to air dry, it can be stored on top of the machine

for drying.

Inspect the squeegee assembly, linkage, and vacuum

hose, for wear, damage or obstruction. Repair or

replace as needed.

Check for debris from squeegee hose at entrance to

recovery tank.

Weekly Maintenance (20 hours)

Verify all daily maintenance has been performed.

Check battery terminals and cable connections.

Tighten as needed. Loose connections are

dangerous and can cause personal injury and

machine damage

Clean any corrosion from battery terminals and

cables.

Drain all liquids from battery compartment. Dispose

of according to local and federal regulations.

Check solution flow to pad driver and / or brush.

Remove, inspect and clean solution filter assembly.

Flush solution tank and hoses with a mixture of

8oz/250 ml white vinegar to 1 gal/4 l water.

Repair or replace any worn or damaged components

as needed.

Inspect and clean float screen and small vac filter

above float.

****CAUTION****

Inspect and replenish battery water in every cell in

every battery weekly. Failure to maintain proper

electrolyte level in every cell of every battery will cause

premature battery failure, and void the warrantee.

Monthly Maintenance (100 Hours)

Equalize your batteries

(Flooded only).

To equalize

the batteries, after they have been fully charged,

unplug the charger (from the wall outlet), and plug it

back in. The charger will skip thru the first few

phases of the charge cycle, and run thru the finish

phase. This will balance out all the cells in the

batteries, and provide maximum battery life. THIS

STEP IS ESPECIALLY IMPORTANT IF YOU

PRACTICE OPPORTUNITY CHARGING.

Verify all daily and weekly maintenance has been

performed.

Lube the caster and swivel bearings. Spray with

Silicone Lubricant.

Inspect all mechanical linkages, pivot points and ball

joints for freedom of movement. Use a penetrating

spray lubricant that is water resistant.

Do not

use

WD-40 lubricant.

Inspect all fasteners (bolts, screws, nuts) at

mechanical linkages, pivot points and ball joints for

tightness. Tighten as needed.

Clean polyethylene body components to remove

chemical and liquid residue and maintain a “like new”

appearance.

Mandatory Periodic Maintenance

It is

mandatory

that the following maintenance procedure

be performed at the described interval. Failure to perform

this procedure may result in poor machine performance,

component damage and failure. This procedure should be

performed by an NSS authorized distributor or service

center. Repairs not performed by an unauthorized

company will void the machine warranty. If you require

assistance finding an authorized service center, contact

NSS Enterprises.

Summary of Contents for 2016 AB

Page 14: ...EC DECLARATION OF CONFORMITY...

Page 15: ...NOTES...