After every

450-500 hours

of operation you must inspect

vac motor carbon brushes for wear. Replace the vacuum

motor carbon brushes when they are 7/16 in. (11 mm) in

length.

After every

650-700 hours

of operation you must inspect

the drive motor (transaxle) carbon brushes for wear.

Replace the drive motor (transaxle) carbon brushes when

they are 3/8 in. (9 mm) in length.

After every

650-700 hours

of operation you must inspect

the brush motor carbon brushes for wear.

Replace the

brush motor carbon brushes when they are 1/2 in. (13 mm)

in length.

Battery Charger

The onboard battery charger supplied with this

machine is capable of charging lead acid batteries

from 185 to 350ah capacity. There is no need to

change algorithms or settings based on battery

manufacturer, or battery size.

The charger can also be set to charge flooded (wet)

cell, AGM, or Gel batteries. LED’s on the charger

indicate which type of battery the charger is set to

charge. One setting is for Flooded and AGM

batteries, the other setting is only for GEL batteries.

Depending on the battery charger model, the charger

can operate on 100/115/230 VAC 1ph 50/60 HZ

power, and will automatically detect these input

voltages. Before connecting the battery charger to

power, check the label on the battery charger to verify

the proper input power.

Determining Your Battery Type

CAUTION: DIFFERENT BATTERY TYPES HAVE

DIFFERENT CHARGING REQUIREMENTS.

FAILURE TO PROPERLY IDENTIFY YOUR

BATTERY TYPE, AND SET THE CHARGER

ACCORDINGLY WILL RESULT IN BATTERY

DAMAGE, AND VOID THE WARRANTEE.

Your machine may have been ordered with batteries

installed at the NSS factory. The standard battery

type, normally supplied by NSS, is the Flooded (wet)

cell lead acid battery. Gel and AGM sealed batteries

may also be available at customer request.

Flooded (wet) batteries can be easily identified by the

removable cell caps. Removing the caps allows

inspection of the liquid electrolyte (sulfuric acid) level

in each cell.

AGM (Absorbed Glass Mat) batteries are sealed,

maintenance free batteries. They do not have cell

caps intended for removal. Look for

“AGM”

printed

on the tops or sides of the batteries.

Gel (gelled electrolyte) batteries are also sealed,

maintenance free batteries. They do not have cell

caps intended for removal. Look for

“GEL”

printed

on

the tops or sides of the batteries.

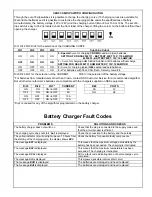

Battery Charger Indicator LED’s

Your battery charger is equipped with LEDs that

indicate the following:

Battery Type Setting. Either of these two

LEDs will be illuminated, anytime the charger

is plugged in, to signal which type(s) of

batteries the charger is configured to charge.

The two options available are:

o

Wet / AGM: When this LED is

illuminated, the charger is configured

to charge either flooded (wet), or AGM

batteries.

o

Gel Cell. When this LED is illuminated,

the charger is configured to charge

Gel batteries ONLY.

EXCEPTION:

Trojan AGMs are to be charged

with the Gel setting.

State of Charge Indicators. Four additional

LEDs provide information about the charge

level of the batteries during charging.

o

30%, 60%, 90% and 100%.

Fault

Indications.

During

charging,

the

charger

provides

feedback

about

the

charge

process

and

any

problems

detected.

It

will

provide

feedback

and

signal

the

type

of

problem

by

flashing

LEDs

as

described

below:

Summary of Contents for 2016 AB

Page 14: ...EC DECLARATION OF CONFORMITY...

Page 15: ...NOTES...