S-63

05-E2B, 05-E2BG, WSM

DIESEL ENGINE

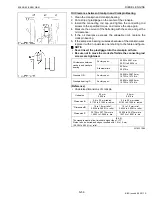

(5) Cylinder

Cylinder Wear

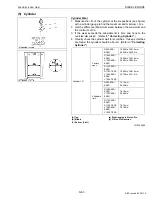

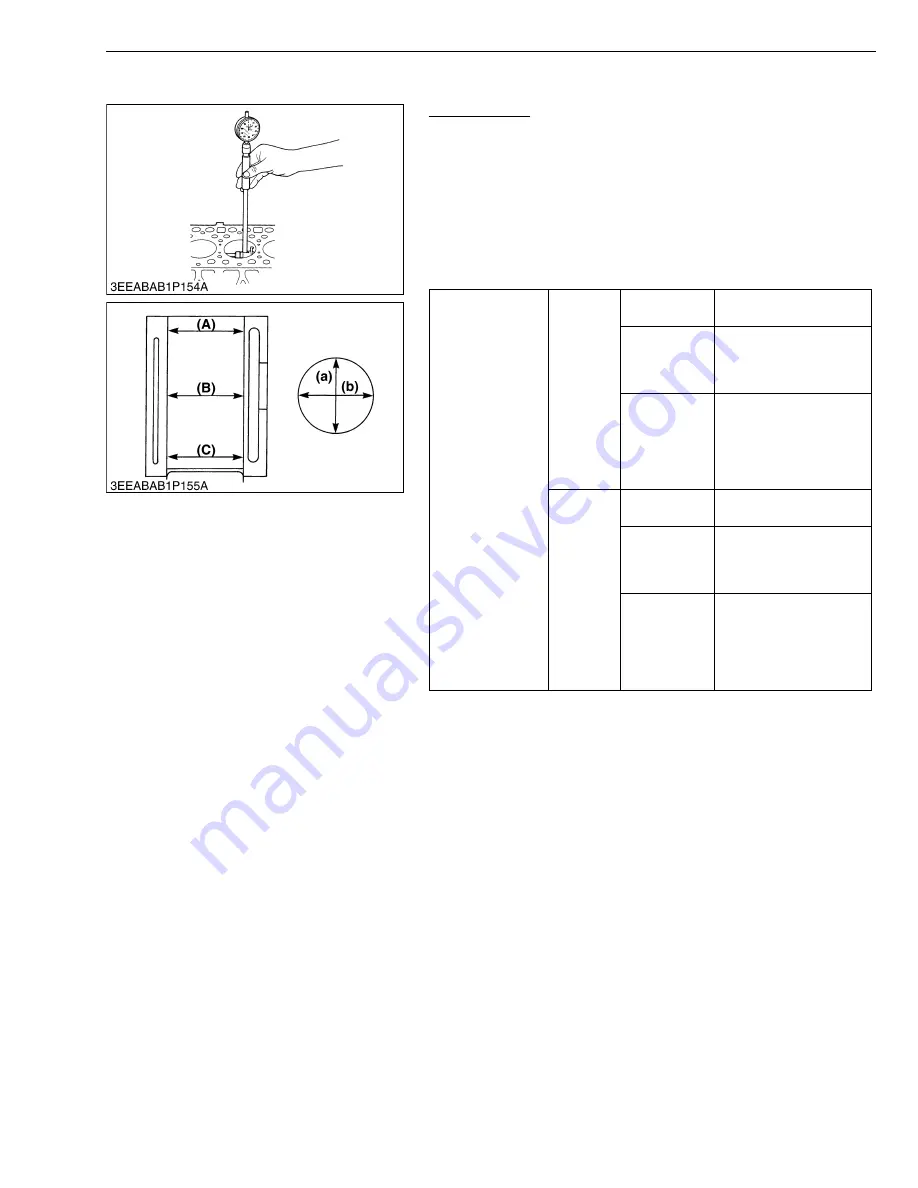

1. Measure the I.D. of the cylinder at the six positions (see figure)

with a cylinder gauge to find the maximum and minimum I.D.’s.

2. Get the difference (Maximum wear) between the maximum and

the minimum I.D.’s.

3. If the wear exceeds the allowable limit, bore and hone to the

oversize dimension. (Refer to

“Correcting Cylinder”

.)

4. Visually check the cylinder wall for scratches. If deep scratches

are found, the cylinder should be bored. (Refer to

“Correcting

Cylinder”

.)

W10343890

Cylinder I.D.

Factory

spec.

D905-E2B /

E2BG

72.000 to 72.019 mm

2.8346 to 2.8354 in.

D1005-E2B /

E2BG

V1305-E2B /

E2BG

76.000 to 76.019 mm

2.9921 to 2.9929 in.

D1105-E2B /

E2BG

D1105-T-E2B

V1505-E2B /

E2BG

V1505-T-E2B

78.000 to 78.019 mm

3.0709 to 3.0716 in.

Allowable

limit

D905-E2B /

E2BG

72.15 mm

2.8406 in.

D1005-E2B /

E2BG

V1305-E2B /

E2BG

76.15 mm

2.9980 in.

D1105-E2B /

E2BG

D1105-T-E2B

V1505-E2B /

E2BG

V1505-T-E2B

78.15 mm

3.0768 in.

(A) Top

(B) Middle

(C) Bottom (Skirt)

(a) Right-angled to Piston Pin

(b) Piston Pin Direction

KiSC issued 06, 2011 A