S-28

05-E2B, 05-E2BG, WSM

DIESEL ENGINE

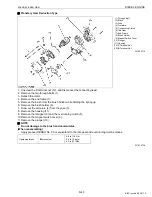

Turbocharger (equipped with Turbocharger Model)

CAUTION

• While the engine is running and or just after it stops, the

turbocharger is hot, be careful not to touch the

turbocharger.

NOTE

Q

• When detaching and attaching the turbocharger assembly,

be very careful not to allow dust, dirt and other foreign

matters in the oil pipes.

• When the turbocharger assembly has been replaced, pour

fresh engine oil through the oil filter port of the

turbocharger.

• Before starting the engine, make sure that the air cleaner

position.

1. Disconnect the intake hose (3).

2. Remove the oil switch (1).

3. Disconnect the pipe band (2).

4. Remove the exhaust manifold with turbocharger.

W1021474

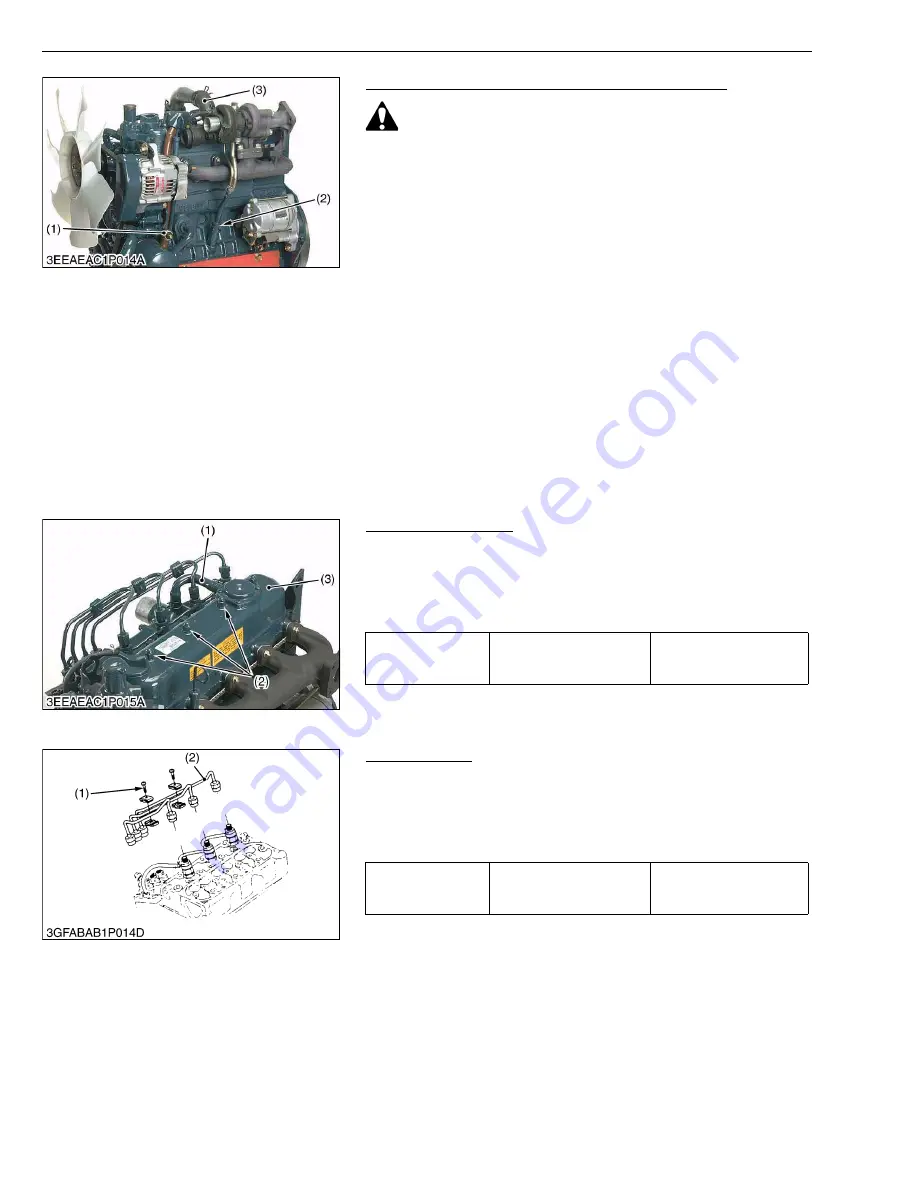

(3) Cylinder Head and Valve

Cylinder Head Cover

1. Disconnect the breather hose (1).

2. Remove the cylinder head cover screw (2).

3. Remove the cylinder head cover (3).

(When reassembling)

• Check to see if the cylinder head cover gasket is not defective.

W1028468

Injection Pipes

1. Loosen the screws to the pipe clamp (1).

2. Detach the injection pipes (2).

(When reassembling)

• Sent compressed air into the pipes to blow out dust. Then,

reassemble the pipes in the reverse order.

W1028640

(1) Oil Switch

(2) Pipe Band

(3) Intake Hose

Tightening torque

Cylinder head cover screw

6.9 to 8.8 N·m

0.7 to 0.9 kgf·m

5.1 to 6.5 ft-lbs

(1) Breather Hose

(2) Cylinder Head Cover Screw

(3) Cylinder Head Cover

Tightening torque

Injection pipe retaining nut

24.5 to 34.3 N·m

2.5 to 3.5 kgf·m

18.1 to 25.3 ft-lbs

(1) Pipe Clamp

(2) Injection Pipe

KiSC issued 06, 2011 A