HYDRAULIC SYSTEM

L4100, WSM

8-S22

(EU)

[3] SERVICING

(1) Hydraulic Pump (Power steering, Three Point System)

Housing Bore (Depth of Scratch)

1. Check for the scratch on the interior surface of the housing

caused by the gear.

2. If the scratch reaches more then half the area of the interior

surface of the housing, replace at pump assembly.

3. Measure the housing I.D. where the interior surface is not

scratched, and measure the housing I.D. where the interior

surface is scratched.

4. If the values obtained in the two determinations differ by more

than the allowable limit, replace the hydraulic pump as a unit.

(Reference)

• Use a cylinder gauge to measure the housing I.D.

9Y1210278HYS0028US0

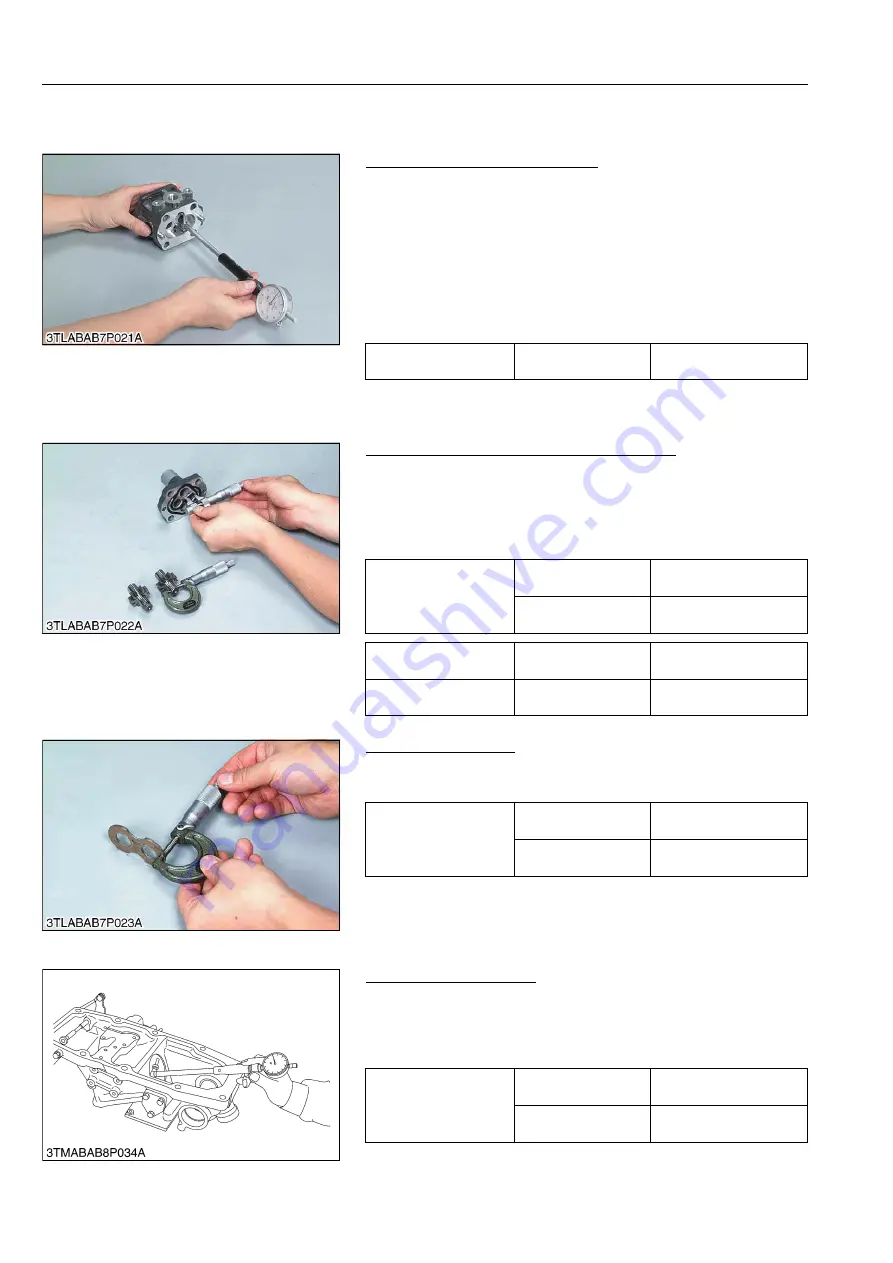

Clearance between Bushing and Gear Shaft

1. Measure the gear shaft O.D. with and outside micrometer.

2. Measure the bushing I.D. with and inside micrometer or cylinder

gauge, and calculate the clearance.

3. If the clearance exceeds the allowable limit, replace the gear

shaft and the bushing as a unit.

9Y1210278HYS0029US0

Side Plate Thickness

1. Measure the side plate thickness with an outside micrometer.

2. If the thickness is less than the allowable limit, replace it.

9Y1210278HYS0030US0

(2) Hydraulic Cylinder

Hydraulic Cylinder Bore

1. Check the cylinder internal surface for scoring or damage.

2. Measure the cylinder I.D. with a cylinder gauge.

3. If the measurement exceeds the allowable limit, replace the

hydraulic cylinder block.

9Y1210278HYS0031US0

Depth of scratch

Allowable limit

0.090 mm

0.0035 in.

Clearance between

bushing and gear shaft

Factory specification

0.020 to 0.081 mm

0.00079 to 0.0031 in.

Allowable limit

0.15 mm

0.0059 in.

Gear shaft O.D.

Factory specification

14.970 to 14.980 mm

0.58937 to 0.58976 in.

Bushing I.D.

Factory specification

15.000 to 15.051 mm

0.59056 to 0.59255 in.

Side plate thickness

Factory specification

2.48 to 2.50 mm

0.0977 to 0.0984 in.

Allowable limit

2.40 mm

0.0945 in.

Cylinder I.D.

Factory specification

90.000 to 90.050 mm

3.5433 to 3.5452 in.

Allowable limit

90.150 mm

3.5492 in.

KiSC issued 08, 2012 A

Summary of Contents for Kubota L4100

Page 1: ...L4100 WORKSHOP MANUAL TRACTOR KiSC issued 08 2012 A...

Page 3: ...I INFORMATION KiSC issued 08 2012 A...

Page 9: ...INFORMATION L4100 WSM I 5 EU 9Y1210278INI0002US0 KiSC issued 08 2012 A...

Page 13: ...INFORMATION L4100 WSM I 9 EU Mid mount type ROPS 9Y1210278INI0006US0 KiSC issued 08 2012 A...

Page 14: ...G GENERAL KiSC issued 08 2012 A...

Page 67: ...1 ENGINE KiSC issued 08 2012 A...

Page 130: ...2 CLUTCH KiSC issued 08 2012 A...

Page 160: ...3 TRANSMISSION KiSC issued 08 2012 A...

Page 161: ...CONTENTS 1 STRUCTURE 3 M1 MECHANISM KiSC issued 08 2012 A...

Page 201: ...4 REAR AXLE KiSC issued 08 2012 A...

Page 202: ...CONTENTS 1 STRUCTURE 4 M1 MECHANISM KiSC issued 08 2012 A...

Page 210: ...5 BRAKES KiSC issued 08 2012 A...

Page 211: ...CONTENTS 1 STRUCTURE 5 M1 2 OPERATION 5 M2 MECHANISM KiSC issued 08 2012 A...

Page 224: ...6 FRONT AXLE KiSC issued 08 2012 A...

Page 225: ...CONTENTS 1 STRUCTURE 6 M1 2 FRONT WHEEL ALIGNMENT 6 M2 MECHANISM KiSC issued 08 2012 A...

Page 245: ...7 STEERING KiSC issued 08 2012 A...

Page 264: ...8 HYDRAULIC SYSTEM KiSC issued 08 2012 A...