4

F

L

O

W

R

E

G

U

L

A

T

O

R

M

A

N

I

F

O

L

D

S

FLOW REGULATOR OVERVIEW

The purpose of the flow regulator is to provide a more precise brix ratio between soda and syrup during pres-

sure fluctuations. The regulators compensate for pressure variances by automatically reducing the amount of

product that passes through when pressure rises, and increasing amounts when pressure falls. Liquid flow

regulators manufactured for post-mix beverage dispensers use a "piston" moving up or down within a

"cylinder". Typically, a small opening at one end of the piston is where the liquid enters. Located within the

hollow piston is an adjustable tension spring which provides resistance against the path of liquid flow.

HOW IT WORKS

Incoming liquid, under pressure, forces the piston upward against the adjusted tension spring. As the piston

moves, the regulating process begins. It partially or fully closes the outlet holes located in the top of the cylin-

der wall. As pressure varies, the piston will move in a direction to open or close the outlet holes to maintain

the preset flow rate.

FACTORY GUIDELINES

The flow control regulator is not a "fix-all" for varying pressures over a wide range. There are limitations, a

minimum operating pressure and a maximum operating pressure. This range is determined by the "Finished

Product" (FP) flow rate. When you lower the FP flow rate, you increase the operating range. Therefore, a

slower FP rate is generally better because lower pressures can be applied to the syrups and this increases

the regulator's accuracy and consistency. To maintain a proper flow and desired "Finished Product (FP), flow

rate must first be established. The following instructions will assist you in adjusting for a flow rate of 1.5

ounces per second of finished product.

CAUTION:

Before you begin to set rates, make certain that all air has been removed from the soda, water

and syrup lines. Air will cause varying flow. Also, be sure to chill all liquid to its normal operating temperature

to assure proper settings.

GENERAL OPERATING INSTRUCTIONS FOR FLOW REGULATORS

Your Flow Regulator Manifold was factory pre-set and tested to the following pressures and flow rates:

Achieving Finished Product Flow Rate of 1.5 Ounces Per Second

1. Set High CO2 pressure to 90 PSI (flow) from the Carbonator

2. Set Low CO2 pressure to 60 PSI (flow) for BIB pumps for Sugar-based syrups.

3. Set Diet CO2 pressure to 20 PSI (flow) for BIB pumps for Diet syrups.

4. Set the Soda flow rate to 6.5 ounces in 5 seconds (See adjustment procedures below)

5. Set Syrup to Soda/Water ratio to 5:1 for most carbonated products. Other ratios will be noted

on the BIB label. However, some specialty beverages have 5.5:1 or higher ratios. Some juices and

mixers have ratios as low as 1:1 to 2:1. Always read the BIB (Bag-In-Box) syrup container label

for ratio specifications before starting. The small chamber (syrup side) of brix cup should fill to 1

oz. in the same amount of time it takes to fill the large chamber 5 oz. of soda or water—confirming

a 5:1 brix ratio (

Fig.5

). If the product was 4:1 ratio, the small chamber would fill to the same 1 oz.

mark, but the soda or water would fill to 4 oz. Repeat until all products are properly brix ratio’d.

At 1.5 ounces per second finished product flow rate, controllable pressure “throw” ranges are:

SODA: 40 to 110 PSI

SUGAR BASED SYRUPS: 20 TO 80 PSI

DIET SYRUPS: 10 TO 40 PSI

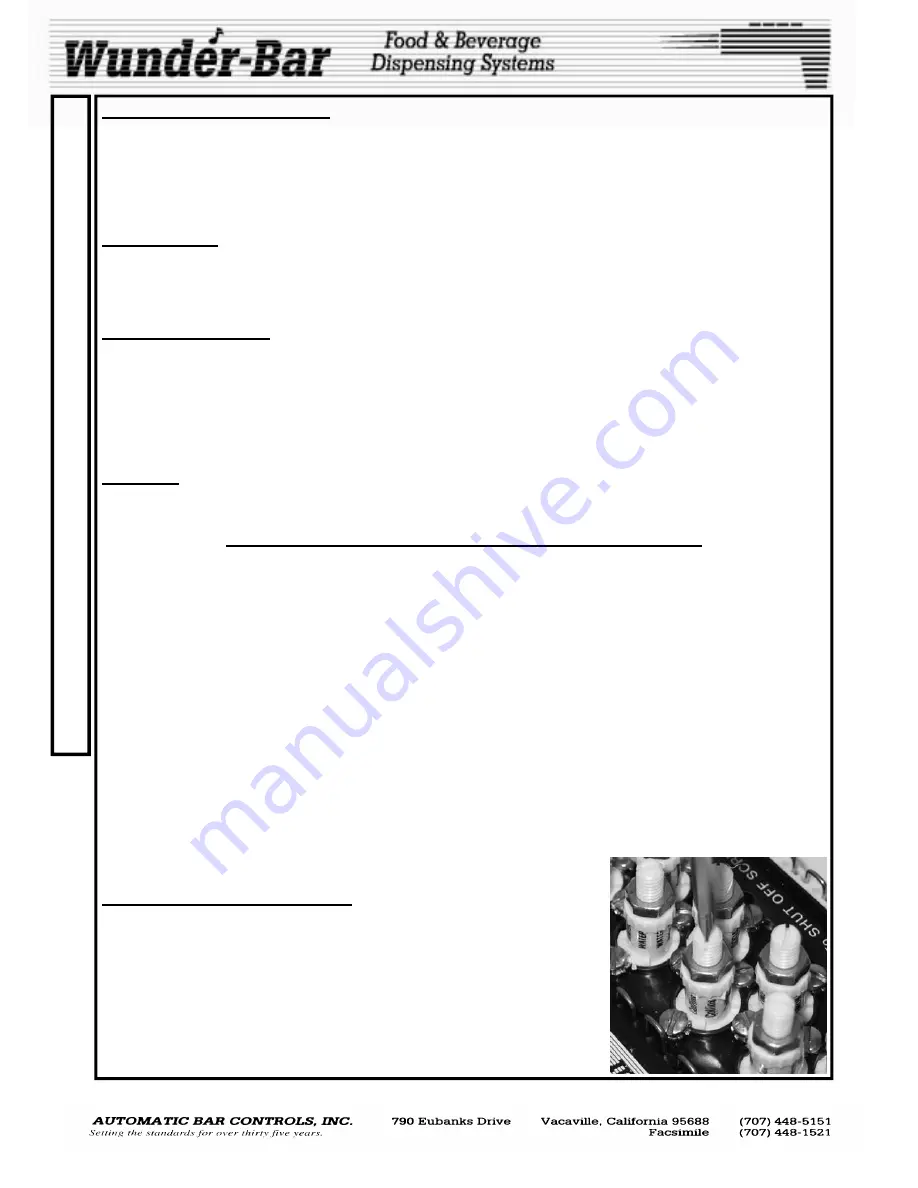

FLOW REGULATOR ADJUSTMENT

Once the Soda and Water flow rates have been set, only adjust the syrup

flow regulator adjustment screws if the ratio is not correct (

Fig.9

). Loosen

the desired syrup’s lock nut first, before attempting adjustments

To decrease the amount of syrup: Turn the adjustment screw counter-

clockwise (

Fig.9

).

To increase the amount of syrup: Turn the adjustment screw clockwise.

Always make adjustments in 1/4 to 1/2 turn increments.

MARK 4 MANUAL

Fig.9

www.wunderbar.com

Summary of Contents for Mark 4

Page 15: ...15 15 www wunderbar com ...

Page 16: ...16 16 www wunderbar com ...

Page 17: ...17 17 www wunderbar com FR 73 ...

Page 18: ...18 18 www wunderbar com ...

Page 19: ...19 20 www wunderbar com ...

Page 20: ...20 19 www wunderbar com ...

Page 21: ...21 21 www wunderbar com ...

Page 22: ...22 www wunderbar com 22 FR 73 ...

Page 23: ...23 23 www wunderbar com ...

Page 24: ...24 24 www wunderbar com ...

Page 25: ...25 25 www wunderbar com ...

Page 26: ...26 26 www wunderbar com ...