14

Error diagnosis

If the soldering station does not operate as

expected, check the following:

■

Is the device connected to the mains (power

cord connected correctly with the socket and the

device)?

■

Is the fuse defective?

Keep in mind that a defective fuse can be an

indicator of a more deep-seated cause. Simply

changing the fuse is usually not sufficient.

■

Is the soldering iron correctly connected to the

power supply unit?

If you have checked the points described above and

the soldering tip does not become hot, check the

heating resistance and the temperature sensor for

continuity using a resistance meter (see Continuity

check for heating element). If there is no continu-

ity, the heating element is defective and has to be

replaced (see Changing heating elements / power

cords).

If continuity is indicated and the fault cannot be

localised, send the soldering iron and the power

supply unit in for repair.

Important!

Have the power supply unit only

repaired by an authorized and electri-

cally qualified person.

There are live components in the

device.

Danger to life in case of improper

inventions!

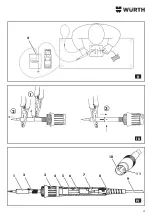

Changing heating elements

[fig. IV]

Continuity check for heating element

The resistance between the measuring point

[10]

and

[11]

should be 6 Ohm (with cold soldering

iron) to 7 Ohm (with higher temperatures) when

measuring the continuity resistance.

If there is no continuity, renew the heating element

(see below).

Changing heating elements / power

cords

■

Disconnect the soldering iron from the station.

■

Extract cooled soldering tip

[1]

and tip fas-

tener

[2]

from the heating element

[3]

.

■

Open strain relief

[8]

with spanner AF12

counter-clockwise (approx. three notches).

■

Unscrew grip-securing screw

[4]

.

■

Remove the grip

[5]

.

■

Loosen the screws on the connector

[6]

between

heating element

[3]

and wires

[7]

.

■

Replace the heating element

[3]

and/or the

power cord

[9]

.

■

Assembly is done in reverse order.

Fixed temperatures

If fixed temperatures are required:

■

After adjusting the required temperature remove

the rotary knob.

■

Remove the protective film from the supplied

cover.

■

Align the mark of the cover with the pre-set

temperature and affix the cover.

The temperatures cannot be changed by unauthor-

ised persons.

Maintenance / Care

Important!

The device may only be cleaned with

the mains plug disconnected.

Environmental protection

Do not dispose of the device with

domestic waste. Have the device

disposed of by an authorised waste

management company or your

municipal waste management

organisation. Adhere to the applica-

ble regulations. In case of doubt

contact your waste management organisation.

Recycle all packaging material in an environmen-

tally friendly manner.

Summary of Contents for 0715 94 50

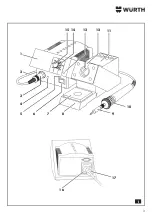

Page 3: ...3 I 1 2 7 3 4 6 8 5 9 10 15 13 14 12 11 17 16 7 6...

Page 4: ...III II 1 2 3 4 IV 4 1 2 3 4 5 6 7 8 9 10 11...

Page 71: ...71 Adolf W rth GmbH Co KG W rth GR...

Page 73: ...73 450 II H 4 220 k III...

Page 74: ...74 IV 10 11 6 Ohm 7 Ohm 1 2 3 8 SW12 4 5 6 3 7 3 9...

Page 119: ...120 Adolf W rth GmbH Co KG W rth BG...

Page 121: ...122 450 4 220 k III...

Page 122: ...123 IV 10 11 6 7 1 2 3 SW12 8 4 5 6 3 7 3 9...

Page 143: ...145 Adolf W rth GmbH Co KG W rth RU...

Page 145: ...147 450 II 4 220 III...

Page 146: ...148 IV 10 11 6 7 1 2 3 12 8 4 5 6 3 7 3 9...

Page 149: ...151...

Page 150: ...152...

Page 151: ...153...