15

■

Press the trigger lever

[9]

once to remove re

-

sidual wax from the hollow space probe.

■

Close the nozzle regulator

[8]

(Fig. 1/V).

■

Close the air regulator

[2]

(Fig. 2/V).

■

Close the air vent regulator

[3]

by turning up

-

wards in an anticlockwise direction (Fig. 3/V).

■

Connect the compressed air supply and com

-

pletely open the air

supply

regulator

[11]

.

■

Press the trigger lever

[9]

up to the first step

to check whether the air vent regulator

[3]

is

closed. If the valve is closed, no air escapes

(Fig. 4/V).

■

Open the air regulator

[2]

by half a turn.

■

Press the trigger lever

[9]

. Air must flow out of

the hollow space probe.

■

Slowly open the air regulator

[8]

(starting with at

least one full turn) and keep the trigger lever

[9]

pressed until hollow space wax flows out of the

probe (Fig. 5/V).

■

Adjust the density of the spray mist using the air

regulator

[2]

(Fig. 6/V).

Note

Do not open the air supply too far,

otherwise the air can close the hollow

space probe and stop the product flow.

■

Set the product quantity with the regulator

[8]

and air supply with the air regulator

[2]

so that

the optimum compromise is achieved between

product quantity and density of the spray mist

(Fig. 7/V).

Conventional products

Setting the product quantity

■

Turn the nozzle regulator

[8]

:

• Clockwise: Product quantity reduces.

• Anticlockwise: Product quantity increases.

Note

Do not exceed the pre-setting. Other

-

wise there is a risk that the regulator

will eject forcefully due to the spring

force.

Setting product atomisation

■

Turn air regulator

[2]

:

—

Clockwise: The air passage reduces and atomi

-

sation reduces (becomes coarser).

—

Anticlockwise: The air passage increases and

atomisation increases (becomes finer).

With open product

■

Pour product into the detachable tank directly.

Note

Fill the bottle with no more than one

litre.

■

Position the detachable tank and tighten in a

clockwise direction (Fig. 4/III and 5/III).

■

If necessary, Set hollow space sealing (see

hollow space sealing chapter).

■

Set the relevant product (see conventional or

water-based product chapter).

■

Point the device at the surface to be sprayed

from a distance of 10 to 30 cm.

■

Press the trigger lever

[9]

.

3

The device sprays.

■

After use, disconnect the device from the

compressed air supply and clean (see section

Maintenance / Care).

Hollow space sealing

Fitting of the hollow space probes

(Fig.

IV)

■

Screws the nozzle cap

[4]

anticlockwise and

remove from the nozzle holder

[5]

.

■

Select the appropriate hollow space probe

[13]

and screw onto the nozzle holder

[5]

in a clock

-

wise direction.

Note

Unscrew the union nut

[6]

and instead

screw the hollow space probe on

to the nozzle holder in a clockwise

direction so that the hollow space

probe is securely screwed on to the

nozzle holder. Then tighten the union

nut again.

Setting hollow space sealing

(hollow space wax) (Fig. V)

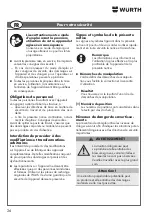

Attention!

Risk of property damage

■

The pressure can also cause the product to

flow out and cause the device to stick strongly

together.

¾

Never completely shut the air regulator

[2]

during use.

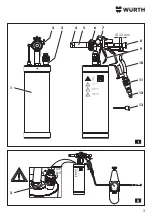

Summary of Contents for 0891 110 640

Page 3: ...10 12 mm AIR EXIT 3 II I 8 7 3 3 1 2 10 11 12 9 4 5 6 13...

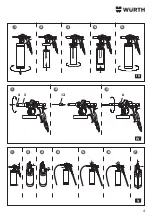

Page 4: ...4 5 5 6 7 4 4 3 3 3 2 2 2 1 1 1 III IV V 4 5 6 13...

Page 82: ...82 GR W rth 3 3 1...

Page 83: ...83 18 16 8 bar...

Page 86: ...86 2 2 11 11 3 4 bar 4 bar 8 2 8 10 12 mm 3 3 2 2 3 2 2 2 3 2 11...

Page 87: ...87 9 11 11 2 45 3...

Page 138: ...138 BG W rth 3 3 1...

Page 139: ...139 18 16 8 bar...

Page 142: ...142 2 2 11 11 3 4 bar 4 bar 8 2 8 10 12 mm 3 3 2 2 3 2 2 2 3 2 11...

Page 143: ...143 9 11 11 2 45 3...

Page 166: ...166 RU W rth 3 3 1...

Page 167: ...167 18 16 8...

Page 170: ...170 2 2 11 11 3 4 4 8 2 8 10 12 3 3 2 2 3 2 2 2 3 2 11...

Page 171: ...171 9 11 11 2 45 3...

Page 173: ...173...

Page 174: ...174...

Page 175: ...175...