16

Attention!

Risk of property damage

■

The pressure can also cause the product to

flow out and cause the device to stick strongly

together.

¾

Never completely shut the air regulator

[2]

during use.

Setting compressed air consumption

■

Turn the air

supply

regulator

[11]

:

• Clockwise: Air flow reduces until it is completely

stopped.

• Anticlockwise: Airflow increases (higher con

-

sumption).

Note

During normal use, the air

supply

regu-

lator

[11]

must be completely open if

the pressure is between 3–4 bar.

It must be adjusted if the pressure is

above 4 bar.

Combined setting

Combined setting of the nozzle regulator

[8]

and

the air regulator

[2]

allows a smooth or rough

surface to be achieved as desired; and thus a finish

matching the original finish of the part being treated

can be achieved.

Water-based products

■

Turn the nozzle regulator

[8]

clockwise to a

maximum 10–12 mm. The nozzle needle is fully

opened and consequently maximum product

flow from the tank is achieved.

Smooth surface setting

■

Completely open the air vent regulator

[3]

(turn

clockwise). During use air flows from the tank

(reducing the pressure available in the tank) and

reduces the product quantity.

■

If spraying is not taking place, slowly turn the air

vent regulator

[3]

anticlockwise until the desired

product quantity is achieved.

■

Fully open air regulator

[2]

.

■

Set atomisation using air regulator

[2]

.

Rough surface setting

■

Slightly close air vent regulator

[3]

(anticlock

-

wise). As a result, the pressure in the tank

increases and with it the product quantity.

■

Slightly close air regulator

[2]

dependent on the

surface.

■

Set atomisation using air regulator

[2]

.

Attention!

Risk of property damage

■

The pressure can also cause the product to

flow out and cause the device to stick strongly

together.

¾

Never completely shut the air regulator

[2]

during use.

Combined setting

Combined setting of air vent regulator

[3]

and air

regulator

[2]

allows a smooth or rough surface to

be achieved as desired; and thus a finish matching

the original finish of the part being treated can be

achieved.

The air

supply

regulator

[11]

is in these cases set to

match the requirements of the operator.

Summary of Contents for 0891 110 640

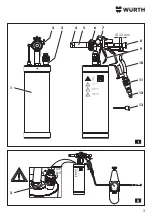

Page 3: ...10 12 mm AIR EXIT 3 II I 8 7 3 3 1 2 10 11 12 9 4 5 6 13...

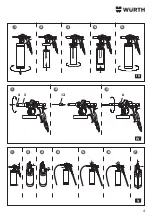

Page 4: ...4 5 5 6 7 4 4 3 3 3 2 2 2 1 1 1 III IV V 4 5 6 13...

Page 82: ...82 GR W rth 3 3 1...

Page 83: ...83 18 16 8 bar...

Page 86: ...86 2 2 11 11 3 4 bar 4 bar 8 2 8 10 12 mm 3 3 2 2 3 2 2 2 3 2 11...

Page 87: ...87 9 11 11 2 45 3...

Page 138: ...138 BG W rth 3 3 1...

Page 139: ...139 18 16 8 bar...

Page 142: ...142 2 2 11 11 3 4 bar 4 bar 8 2 8 10 12 mm 3 3 2 2 3 2 2 2 3 2 11...

Page 143: ...143 9 11 11 2 45 3...

Page 166: ...166 RU W rth 3 3 1...

Page 167: ...167 18 16 8...

Page 170: ...170 2 2 11 11 3 4 4 8 2 8 10 12 3 3 2 2 3 2 2 2 3 2 11...

Page 171: ...171 9 11 11 2 45 3...

Page 173: ...173...

Page 174: ...174...

Page 175: ...175...