17

Maintenance / Care

WARNING!

Injuries or material damage due to

improper actions.

¾

Disconnect the device from the air

supply before carrying out any

service or maintenance work.

■

Empty detachable tank or remove bottle.

■

Pour a sufficient amount of a suitable thinner for

the product used into the empty detachable tank

or the bottle.

■

As the case may be Position the bottle and

tighten in a clockwise direction.

■

Position the detachable tank and tighten in a

clockwise direction.

■

Connect the device to the air supply again.

■

Spray solvent into a special container until the

device is clean.

When doing so completely close the regulator,

to prevent atomising of the solvent, which

could result in contamination of the immediate

surroundings.

Note

Do not immerse the device completely

in the solvent; clean using a soft brush

or cloth.

■

Do not clean the components of the device using

wire brushes or sandpaper.

■

On no account should acids or alkaline

cleansing agents be used for cleaning.

■

If necessary lubricate the nozzle needle and air

vent rod.

■

Check the thread regularly for wear to ensure

parts such as the tank or adjustment wheel do

not unintentionally become loose.

■

After cleaning, maintenance and/or repair

work, check that all screws and nuts are securely

tightened.

Environmental Instructions

Do not throw the device away with

normal household waste. Dispose of

the device via an approved waste

disposal company or via your local

authority waste disposal facility.

Observe the currently valid regula

-

tions. In case of doubt, contact your

waste disposal facility. Dispose of all packaging in

an environmentally sound manner.

Troubleshooting

Fault

Possible cause

Remedy

Device does not spray when the

trigger lever

[9]

is pressed

No air supply, air

supply

regulator

[11]

closed

Open air

supply

regulator

[11]

or air

regulator

[2]

Spraying result irregular

Vertical tube dirty or blocked

Clean all tubes and spray nozzle

Never tip the device through more

than 45°

The tank cannot be unscrewed

Residual pressure in the tank

Open the tank air vent regulator

[3]

to allow pressure to escape

Difficult to screw the bottle on to

the device

The cartridge aluminium seal is

not correctly open

Widen the opening with a sharp

object or the device’s vertical tube

Summary of Contents for 0891 110 640

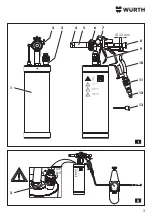

Page 3: ...10 12 mm AIR EXIT 3 II I 8 7 3 3 1 2 10 11 12 9 4 5 6 13...

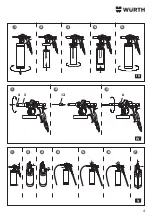

Page 4: ...4 5 5 6 7 4 4 3 3 3 2 2 2 1 1 1 III IV V 4 5 6 13...

Page 82: ...82 GR W rth 3 3 1...

Page 83: ...83 18 16 8 bar...

Page 86: ...86 2 2 11 11 3 4 bar 4 bar 8 2 8 10 12 mm 3 3 2 2 3 2 2 2 3 2 11...

Page 87: ...87 9 11 11 2 45 3...

Page 138: ...138 BG W rth 3 3 1...

Page 139: ...139 18 16 8 bar...

Page 142: ...142 2 2 11 11 3 4 bar 4 bar 8 2 8 10 12 mm 3 3 2 2 3 2 2 2 3 2 11...

Page 143: ...143 9 11 11 2 45 3...

Page 166: ...166 RU W rth 3 3 1...

Page 167: ...167 18 16 8...

Page 170: ...170 2 2 11 11 3 4 4 8 2 8 10 12 3 3 2 2 3 2 2 2 3 2 11...

Page 171: ...171 9 11 11 2 45 3...

Page 173: ...173...

Page 174: ...174...

Page 175: ...175...