15

8 – RISKS

)!-¢0.0/0.,/,0%+(%(0¼,!(!,".0$,0,/µ!(

you are working with products which could ignite.

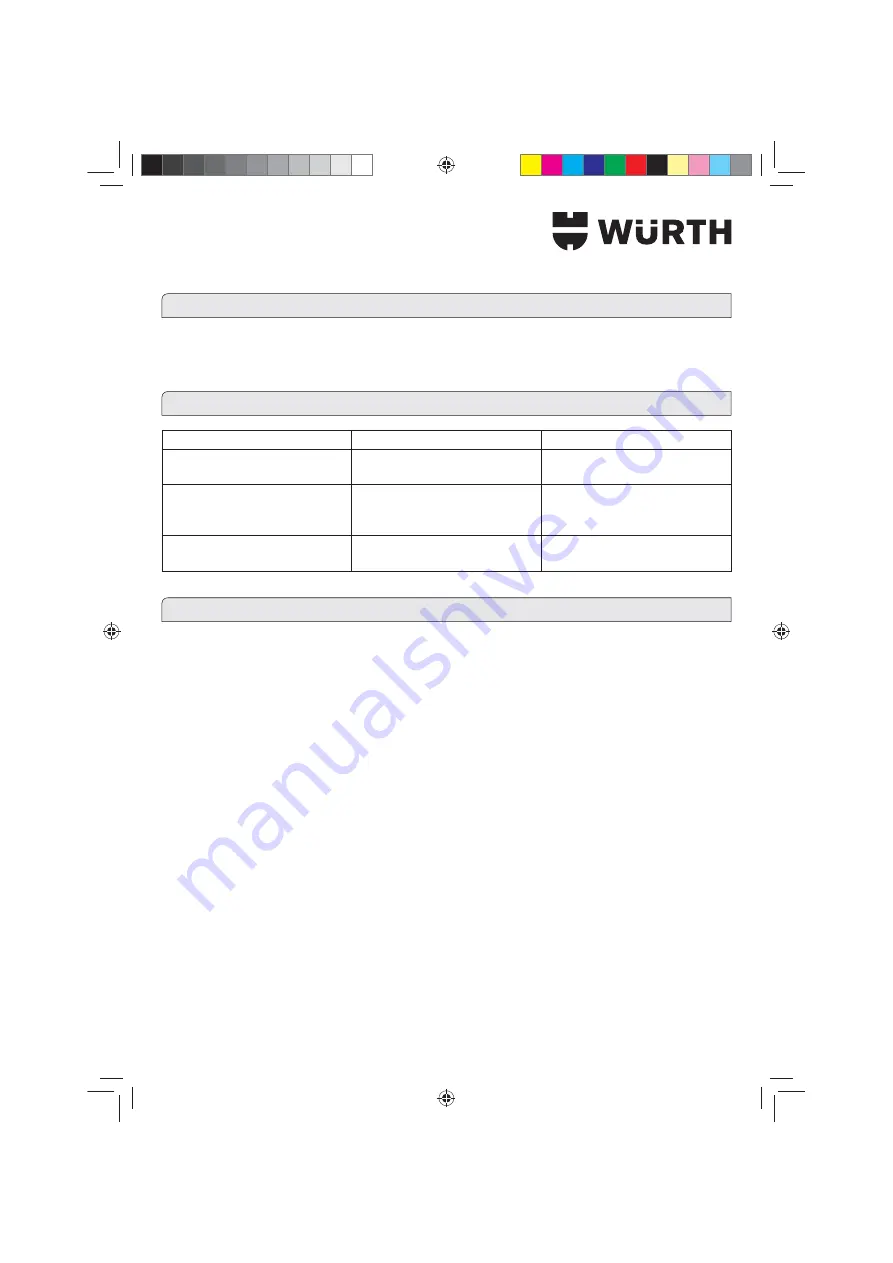

9 – TROUBLESHOOTING

PROBLEMS CAUSES

CORRECTIVE

MEASURES

The gun does not spray when the

triggering lever is actuated.

No supply

Open the manual regulator (19).

Irregular spraying results

Supply hose soiled or clogged

Clean all lines and the spraying

nozzle. Do not tilt the spray gun at

an angle greater than 45°.

)"+,¢(+0,

Residual pressure in the tank

Pull the ring of the safety valve

(41).

10 – MAINTENANCE AND CARE

10.1 Disconnect the spray gun from the air supply.

10.2 Empty the product out of the spray gun into a suitable container.

10.3 Pour the required quantity of a thinner suitable for cleaning (0.5 L) into the tank.

10.4 Close the tank and reattach the spray gun.

10.5 Spray the solvent into a suitable catch container.

Make sure that the positioning regulator (9) is completely closed to prevent atomization of the solvent.

Otherwise, this could result in dirtying of the immediate environment.

Do not completely immerse the spray gun in the solvent, but rather clean it with a soft brush or a cloth instead.

±%¢+$$,0,++(,-º-,%(0,",".¢"¡.

the spray gun on the special hook.

±Â$%(2+(($,+¿!/,/,,(¡.//+¡.(¢%+¡%(0¡-

is voided. In many cases, orderly repairs can only be carried out using special tools. In such cases, limit

yourself to determining the cause of the problem and leave the repair work to the technical department of

your sales partner.

BDA_Druckbecherpistole_HRS2.indd 15

14.03.13 13:28

Summary of Contents for 0891 130

Page 81: ...81 3 3 3 q BDA_Druckbecherpistole_HRS2 indd 81 14 03 13 13 28...

Page 84: ...84 0 q 3 q q 3 q 9 9 BDA_Druckbecherpistole_HRS2 indd 84 14 03 13 13 28...

Page 85: ...85 19 q 19 BDA_Druckbecherpistole_HRS2 indd 85 14 03 13 13 28...

Page 86: ...86 3 3 BDA_Druckbecherpistole_HRS2 indd 86 14 03 13 13 28...

Page 122: ...122 BDA_Druckbecherpistole_HRS2 indd 122 14 03 13 13 28...

Page 123: ...123 BDA_Druckbecherpistole_HRS2 indd 123 14 03 13 13 28...