11

Burn back time

Because of inertia of wire feeder, welding wire do not stop immediately, so small droplet is created on

top of wire. To eliminate this adverse factor machine is equipped with burn back function. When user

stops welding machie still keep output voltage for certain amount of time so the wire burns back and

eliminates the bulb.

Gas post-flow

In order to protect the welding area, when end of the welding still have gas for protect (last 3S).

MMA function

When put the switch under the MMA, wlding machine can work with electrodes.

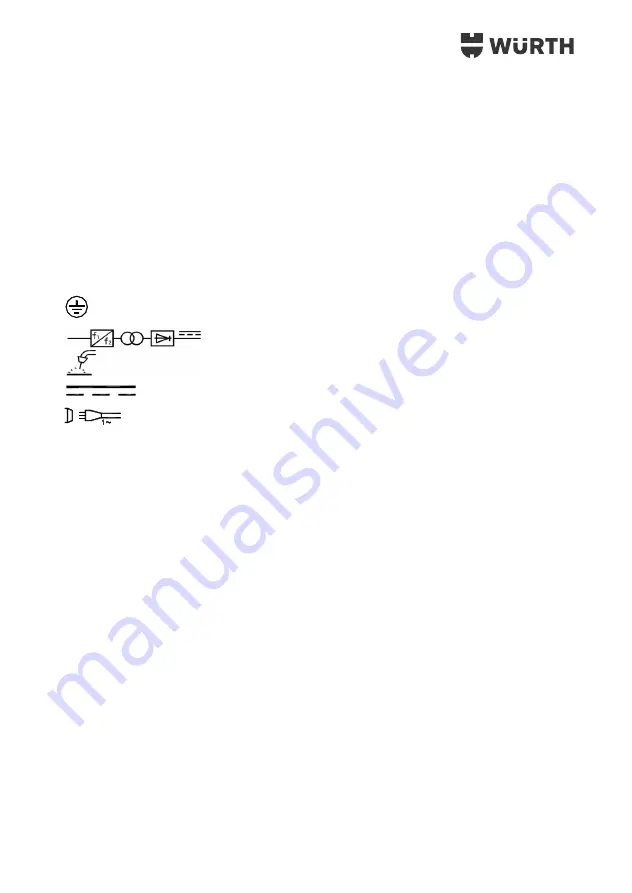

Sign & Pictures Illustration

Ground

Three phase stillness transducer–transformer–rectifier

MIG/MAG welder

DC current

Three phases AC power source

X

Duty Cycle

I1max

Max Input Current

I1eff

Effective Input Current

I2:

Rated Welding Current

U0

Rated Open Circuit Voltage

U1

Rated Input Voltage

U2

Rated Load V

V

Voltage

A

Amperage

%

Duty Cycle

A/ V~ A/ V:

Output Range, Rated Minimum, Rated Maximum Welding Current

and

elated Load Voltage

EN60974-1

International Standard, Welding Equipments – Part 1: Welding Power

Sources

IP21S

Case protection class. IP is the code of International Protection. 2 mean

preventing user’s finger from the dangerous parts; preventing the solid

material with the diameter no less than 12.5 mm into the box. 1 means

preventing water dropping vertically which is harmless. S means water

proof test is conducting while the movable parts are standstill.

H

Insulation Grade H