35

DEU

ENG

NDL

FRA

ITA

ESP

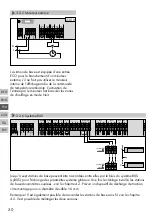

4.5.2 Configuration with room control unit Wireless Display (continued)

No.

Parameters

Description

Unit

040 External sensor connected to

the RBG

Logging on an additional sensor for the registration of the

floor temperature (FBH), the room temperature or the dew

point

no sensor=0

Dew point sen.=1

Temp FBH=2

Temp room=3

060 Correction of actual value

registration

Registration of the actual temperature with a correction factor -2.0...+2.0 K

in 0.1 increments

110 Control direction

switching outputs

Switchover of NC and NO actuators (only globally)

NC=0 / NO=1

115 Use as setback input

Change-over between use of the ECO input for setback or

holiday function of the room control unit.

The holiday function cannot be activated any longer via the

room control unit if this parameter has been set to 1.

ECO=0

Holiday=1

120 Unit of temperature display

Toggle function of the display between degree Celsius and

degree Fahrenheit

°C=0

°F=1

Pump configuration

130 Pump output

Use the control of a local recirculation pump (in the heating

circuit distributor) or a global recirculation pump (heating

installation).

local=0

global=1

131 Pump type

Selection of the used pump: Conventional Pump (KP) / High

efficiency Pump (HP)

CP=0

HP=1

132 Pump line-up time

Time elapsing from the moment of the command from a

switching output until the pump is actually switched on.

[min]

133 Pump follow-up time

Time elapsing from the moment of switching off the switching

outputs until the pump is actually switched off.

[min]

134 Control direction switching

output

The control direction can be inverted if the pump relay is used

as control output

normal=0

inverted=1

135 Minimum running time

The minimum running time indicates how long the HP must run

until it may be switched off again.

[min]

136 Minimum standstill time

High efficiency pump: The pump may only be switched off if

a minimum standstill time can be ensured.

[min]

Configuration of change-over functionality / boiler relay

140 Function of relay boiler / CO

output

Selection whether the switching output shall serve for control-

ling a pump relay, or as CO pilot

Boiler=0

CO pilot=1

141 Line-up time

Boiler relay line-up time for conventional pump

[min]

142 Follow-up time

Boiler relay follow-up time for conventional pump

[min]

143 Control direction switching

outputs

The relay function can be inverted if used as a control output. normal=0

inverted=1

160 Antifreeze protection

Activation of control outputs for T

actual

<x °C

Deactivated=0

Activated=1

161 Antifreeze temperature

Antifreeze function limit value

[°C]

170 Smart Start

Learning-in of the temperature behaviour of the individual

heating zones

Deactivated=0

Activated=1