Operation Manual – Crimp Tool

02

www.we-online.com

Preface

The Operating Instructions must always be within

reach of the hand crimping tool. This Crimp Sys-

tem Tool may be used only for the intended appli-

cation and in strict compliance with all applicable

safety rules, regulations and practices. It must be

properly maintained, undamaged and in good

working order. Unauthorized modification is pro-

hibited and voids the manufacturer’s warranty.

Always wear safety glasses with side shields and

other appropriate personal protective equipment.

MISUSE MAY CAUSE PERSONAL

INJURY. KEEP OUT OF REACH

OF CHILDREN!

NEVER INSERT FINGERS BETWEEN

THE JAWS OF THE TOOL!

!

1

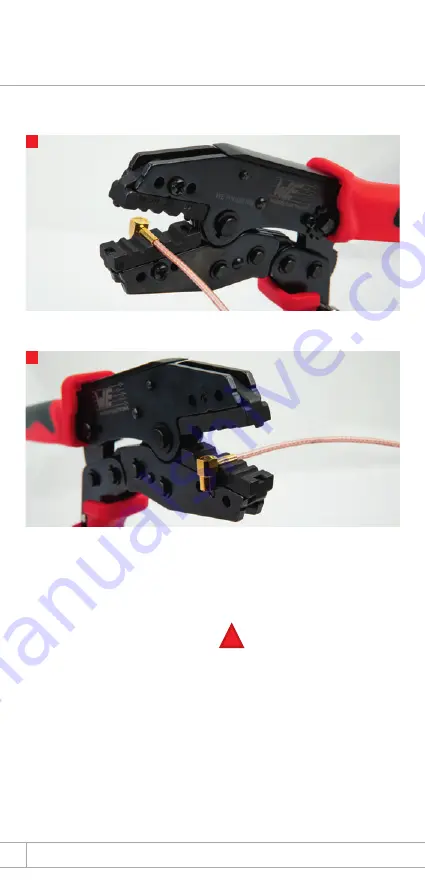

Crimp Steps

Make sure ferrule is well sit in crimp head slot.

Locate ferrule at appropriate hex size according to datasheet.

2