630140_1

XFIRE_1200_GB

_Service_R

‐

em

otion

Flue

25

mm

25

mm

25

mm

50

mm

50

mm

25

mm

25

mm

25

mm

8.0

Clean

Thermocouple:

With

the

Pilot

Cover

removed

you

now

have

access

to

clean

the

thermoco

uple.

Do

this

by

wipi

ng

it

down

with

a

rag

or

other

approp

riat

e

cleaning

tools

in

order

to

remove

any

soot

from

the

surface.

9.0

Paint

Firebox

[if

required]

:

If

there

are

any

scrapes

or

damage

to

the

paint

on

the

inside

of

the

firebox

you

may

wish

to

touch

up

the

paint.

To

do

this,

use

a

suitable

high

temperature

matt

black

paint.

Do

not

put

any

paint

on

the

burner,

as

there

is

a

risk

of

blocking

burner

port

s.

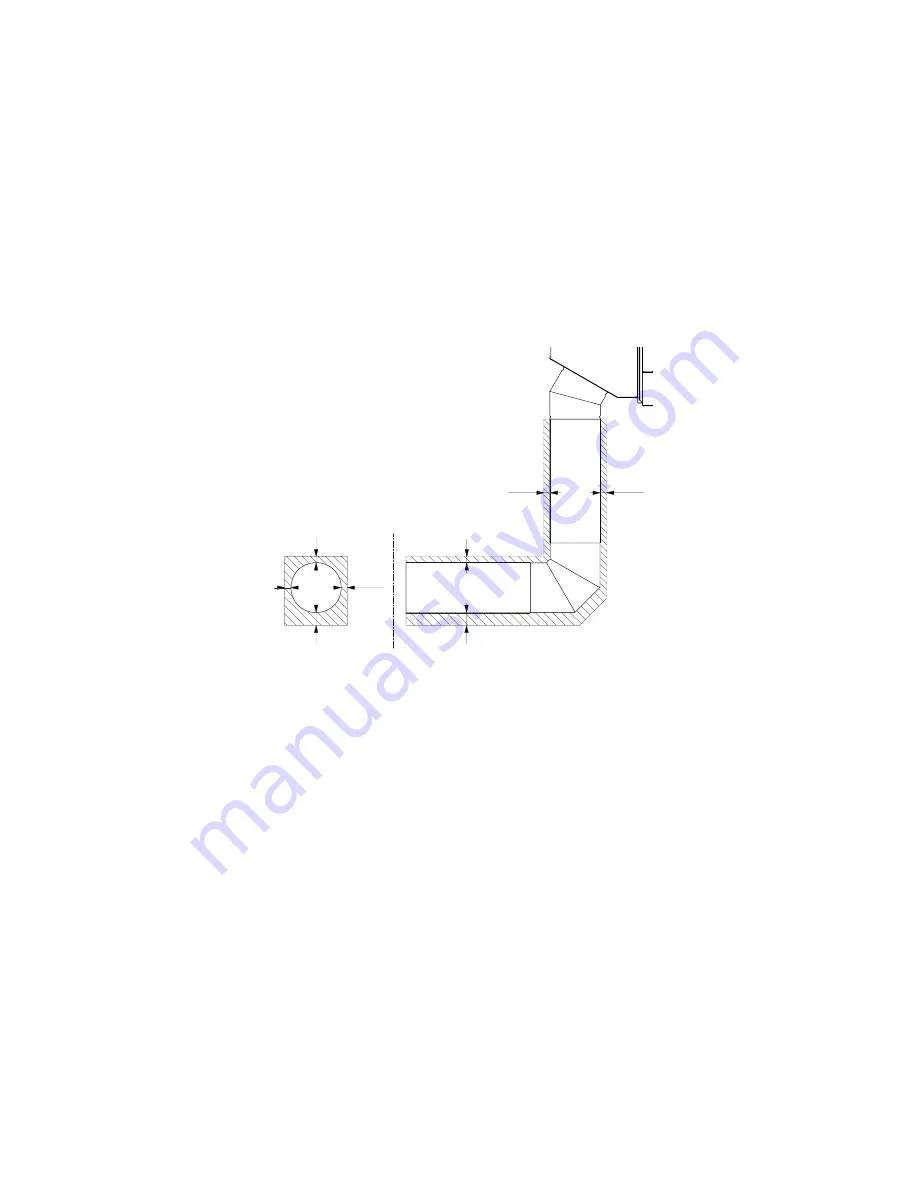

10.0

Inspect

Flue

System

[if

possible]

:

If

you

have

access

to

the

flue

system

,

inspect

it

for

damage

or

potentia

l

blockages

(including

the

cowl).

Ensure

each

flue

component

is

twist

‐

locked

into

the

adjacent

components,

and

that

there

are

no

combustible

objects

or

material

within

25mm

of

either

side

or

below

flu

e

components

or

50mm

above

any

flue

components,

as

shown

in

the

diagram

below:

11.0

Gene

ral

Clean

and

Inspection:

A

general

clean

of

the

fire

shoul

d

be

undertaken

by

wiping

down

or

dusting

all

accessible

areas

and

surfaces.

12.0

Re

‐

assemb

le

Once

the

service

work

is

complete,

the

fire

should

be

re

‐

assembled

by

reversing

the

actions

done

in

previous

step

s,

replacing

the

Pilot

Cover,

Burner,

Fuel

bed

media,

Glass

assembly,

and

Control

Tray

(if

removed).