Insulation Blowing Machine M99

Page 50 of 51

X-Floc Dämmtechnik-Maschinen GmbH

Rosine-Starz-Straße 12 · 71272 Renningen · Germany

Phone +49-7159-80470-30 · Fax -40 | info@x-floc.com · www.x-floc.com

7.4

Index

Additional ..................................................................................... 27

Additional switch box ................................................................. 9

Air ............................................................................................. 17, 19

Air filter .......................................................................................... 30

Air flow ................................................................................... 18, 20

Air supply ......................................................................................... 7

Air supply unit ............................................................................ 13

Air volume .................................................................................... 13

Airlock feed gate .......................................................... 13, 24, 31

Airlock feed gate scale ................................................................ 8

Airlock rotational speed .......................................................... 24

Airlock rotational speed control .......................................... 13

Antenna ........................................................................................ 19

Appendix ...................................................................................... 34

Assembling .................................................................................. 14

Automatic blowing ................................................................... 13

AUX ................................................................................................. 19

Auxiliary power socket ............................................................ 11

Battery LED .................................................................................. 19

Battery status .............................................................................. 20

Blower power selector ............................................................. 10

Blower selector switch ............................................................. 10

Bottom of the machine .............................................................. 9

Cable reel ...................................................................................... 15

Cable remote control KFB 3 ................................................... 17

Carbon brushes .......................................................................... 31

Catch seal for the hopper .......................................................... 9

Circuit diagrams ......................................................................... 35

Cleaning ................................................................................. 27, 31

Conditioning unit .................................................................. 8, 30

Conditioning unit fault light .................................................. 10

Conditioning unit maintenance button ............................ 10

Conditioning unit maintenance function......................... 29

Connecting .................................................................................. 14

Connection cable ............................................................... 17, 19

Connection plug ................................................................. 17, 19

Control activation ...................................................................... 20

Control connection ................................................................... 16

Control elements ....................................................................... 10

Conveying height ...................................................................... 13

Deceleration time setting ....................................................... 21

Decommissioning ..................................................................... 26

Delivery contents ...................................................................... 12

Delivery pressure ....................................................................... 13

Dimensions .................................................................................. 13

Disposal ......................................................................................... 33

Electric Switchboard .................................................................... 8

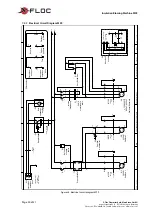

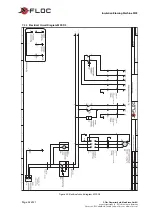

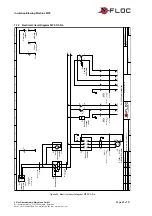

Electrical circuit diagram M99 .............................................. 40

Electrical circuit diagram M99-DS ....................................... 42

Electrical circuit diagram M99-DS-Pro ............................... 45

Emergency ...................................................................................... 6

Emission sound pressure level ................................................ 7

Empty weight .............................................................................. 13

Engine power .............................................................................. 13

Environmental protection ...................................................... 33

Fan power .................................................................................... 13

Faults .............................................................................................. 32

FFB 2000-Pro ................................................................................ 22

Filling height ............................................................................... 13

Filling hopper .............................................................................. 13

Final decommissioning ........................................................... 33

Full diagram ................................................................................... 8

Functional interferences ........................................................... 7

Functionality ................................................................................ 23

Gaskets ........................................................................................... 29

Gear boxes .................................................................................... 31

General ............................................................................................ 6

Hand-held control and receiver configuration ............... 22

Handle .............................................................................................. 8

Hopper ............................................................................................. 8

Hopper extension ........................................................................ 8

Icons .................................................................................................. 5

Initial commissioning ............................................................... 25

Initial operation .......................................................................... 25

Installation site ............................................................................ 14

Insulation materials ..................................................................... 7

Intake socket ........................................................................... 9, 13

Internal Hosing ........................................................................... 31

Key lock settings ......................................................................... 20

KFB 2000 ........................................................................................ 18

Machine control ......................................................................... 13

Machine control socket ........................................................... 11

Machine operation .................................................................... 20

Main connection ........................................................................ 11

Main switch .................................................................................. 10

Mains voltage display ............................................................... 10

Maintenance ................................................................................ 27

Maintenance intervals .............................................................. 28

Material ................................................................................... 17, 19

Material flow ......................................................................... 18, 20

Material flow rate ....................................................................... 13

Material flow volume selector ............................................... 10

Minimum blowing pressure ................................................... 13

Minimum filling level ................................................................ 26

Motor ................................................................................................ 8

Normal operation ...................................................................... 25

OFF ........................................................................................... 17, 19

Operating hours meter ..................................................... 10, 31

Operation ...................................................................................... 17

Operational readiness .............................................................. 25

Operator .......................................................................................... 6

Optional accessories ................................................................. 34

Outlet ........................................................................................ 8, 13

Outlet Connection ..................................................................... 16

Overheating ................................................................................... 7

Overvoltage ................................................................................. 15

Packaging density ..................................................................... 13

Packaging material .................................................................... 14

Parameter list for the frequency convertor ...................... 48

Power connection ..................................................................... 15

Power supply ............................................................................... 13

Precrushing .................................................................................. 26

Preface ............................................................................................. 4

Preparation................................................................................... 14

Pressure detection unit............................................................ 30

Pressure regulator ..................................................................... 11

Pressure test................................................................................. 30

Qualified electrician .................................................................... 6