Page 4 of 18

Intended Use

The Hydraulic motor stays cooler during long pulls. The two-stage planetary gear system provides fast

line speed. The automatic load-holding brake insures maximum safety. The free spooling provides a

fast line-out.

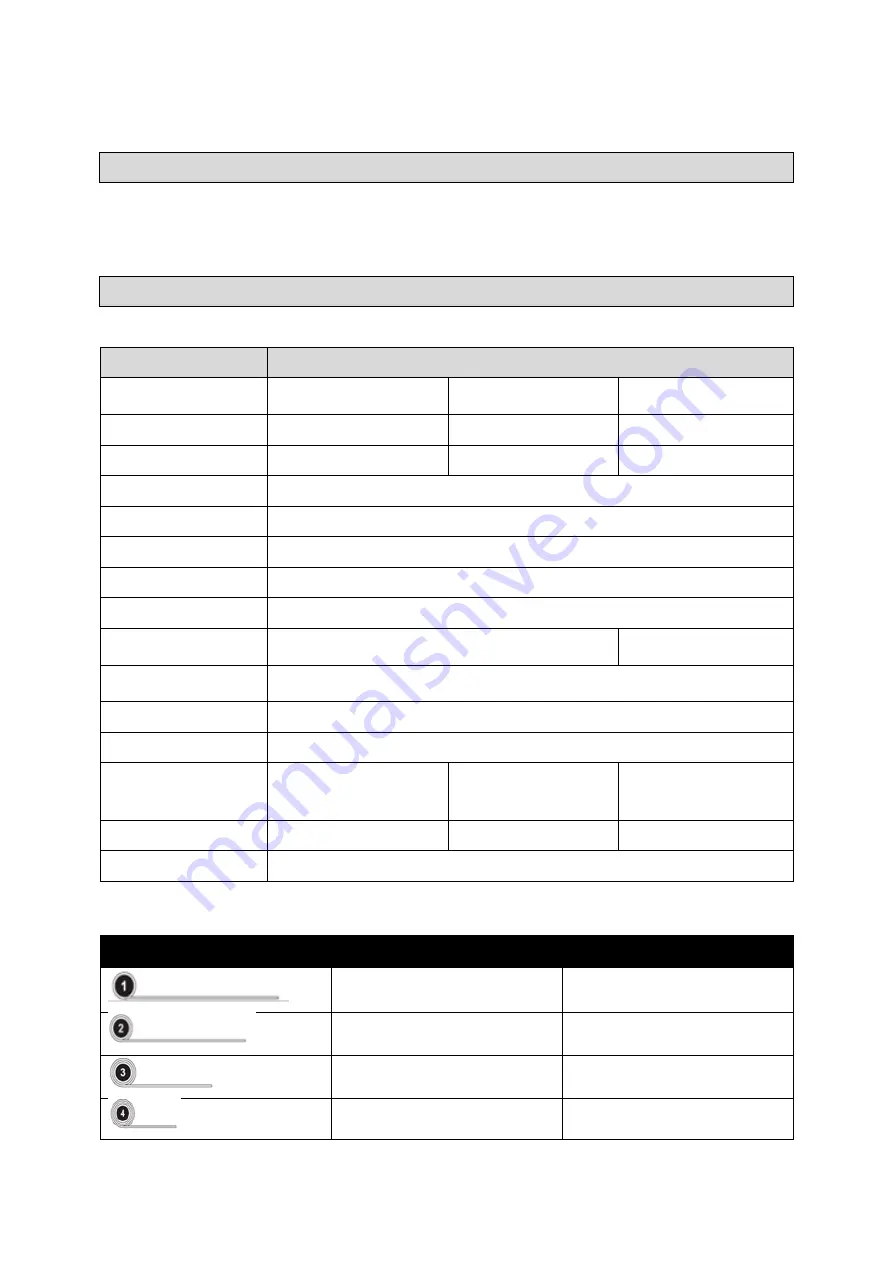

Technical Specifications

Part Number: 10801505

、

10801506

、

10801507

Property

Specification

Rated Single Line Pull

10801505

12,000Ib (5443kg.)

10801506

10,000Ib (4536kg.)

10801507

8,000Ib (3629kg.)

Motor displacement

100 ml/rev

80ml/rev

50ml/rev

Max. flow

55

l/min

55

l/min

40

l/min

Max pressure

12Mpa

Gear Train

2-stage Planetary

Gear Ratio

33:1

Free spool

Locking Ring Gear

Braking Action

Automatic Hydraulic Brake

Drum (Dia. XL)

4.3" x 8.3" (108mm x 211mm)

3.5" x 8.3" (90mm x

211mm)

Mounting Bolt Pattern

10’’x 4.5’’ (254mm x 114.3mm)

10’’’ x 6.5’’(254mm x 165.1mm)

Mounting Hardware

Winch: 8×M12-1.75×35mm

Sound Rating

80dB

Overall Dimensions

(LXDXH)

24.1" X 10.4" X 9.45’’

(612mm X265mm

X305mm)

23.9" X 10." X 9.45’’

(608mm X265mm

X305mm)

23.7" X 10." X12’’

(602mm X265mm

X305mm)

Weight

118Ib (53.52kg)

117Ib (53kg)

114Ib (51.7kg)

IP Rating

IP68-Winch and Controls

Part Number: 10801505

Layer

Rated Line pull

Rope Length/ Layer

12000lb(5443kg)

21.7

’(6.6m)

10000lb(4536kg)

46.4

’(14.1m)

8571lb(3888kg)

73.3

’(22.4m)

7500lb(3402kg)

98.4

’(30m)