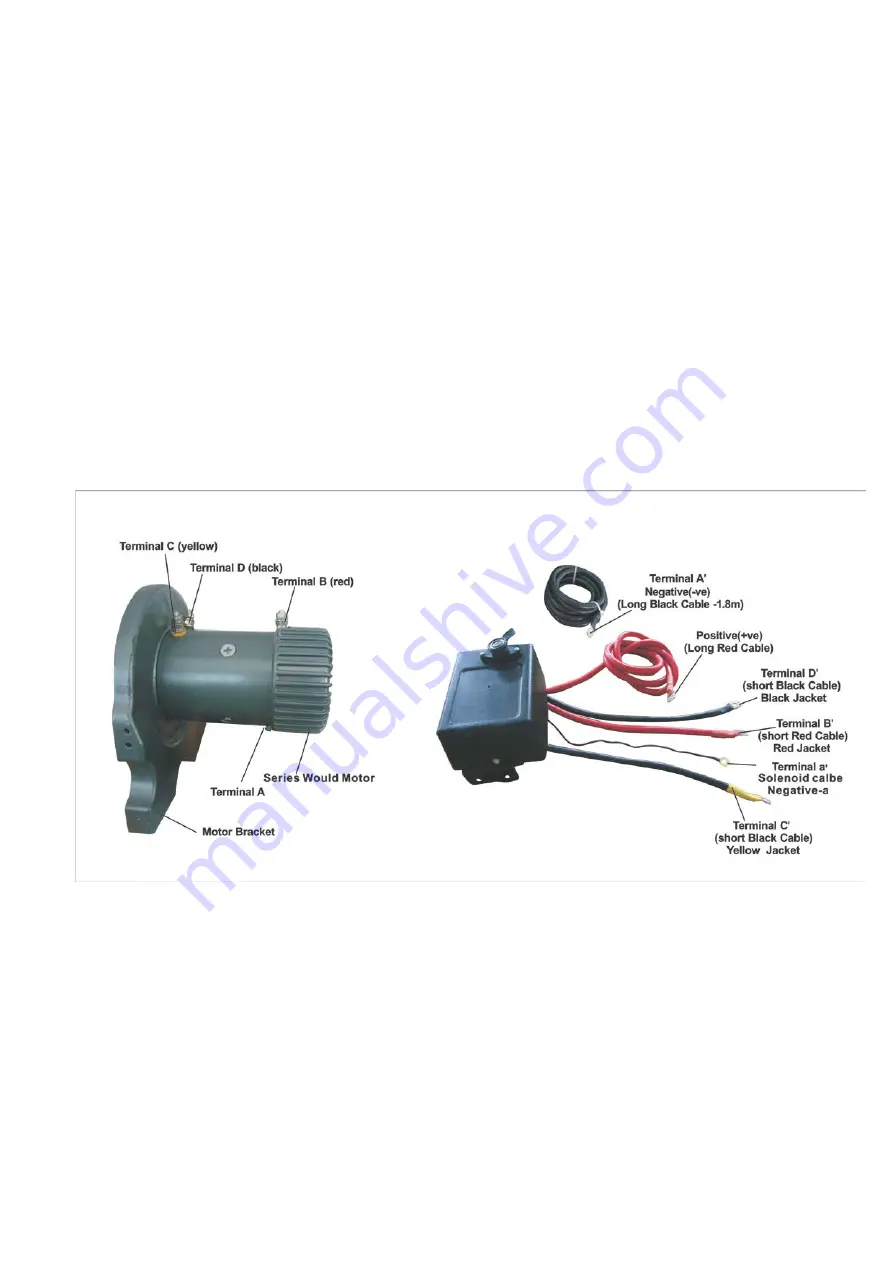

ELECTRICAL CONNECTION

For normal self -recovery work, your existing electrical system is adequate. A fully charged battery and proper

connections are essential. Run the vehicle engine during winching operations to keep battery charged.

Pay close attention to proper electrical cable connection as follows(refer to Diagram1)

1. Short red cable (B') connecting to the red terminal (B) of the motor.

2. Short black cable with yellow jacket (C') connecting to the yellow terminal (C) of the motor.

3. Short black cable with black jacket (D') connecting to the black terminal (D) of the motor.

4. Thin black cable(a') connecting to bottom terminal (A) of the motor.

5. Long black cable (1.8m), one terminal (A') connecting to the bottom terminal (A) of the motor, and the other

terminal

negative (-) connecting to negative (-) terminal of battery.

6. Long red cable positive (+) connecting to positive (+) terminal of battery.

NOTE:

1. Your battery must be kept in good condition.

2. Be sure battery cables are not drawn taught across any surfaces, which could possibly damage them.

3. Corrosion on electrical connections will reduce performance or may cause a short.

4. Clean all connections especially in remote control switch and receptacle.

5. In salty environments use a silicone sealer to protect from corrosion.

6. Index the heads of the plate studs into the keyhole slots on the back of the winch.

7.Attach the winch/Adaptor Plate assembly to your trailer hitch, by inserting the trailer hitch ball through the shaped

hole in the Adaptor Plate.