ENGLISH

7.

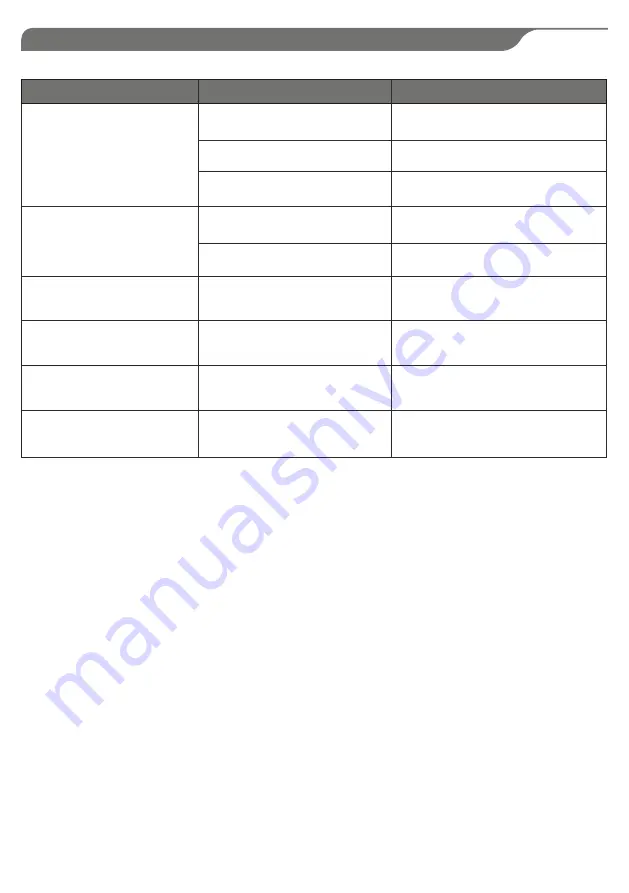

TROUBLESHOOTING AND PROPOSED SOLUTIONS

Pressure BOOSTER application:

PRESSURE SWITCHES OFF

status with low pressure system

Possible failure of the pressure switches

FREQUENT PROBLEMS

CAUSES

OPERATION

Feed the control panel respecting

the input voltage

Set the switch on 1

Connect the flat cable from the motherboard

to the display

Switch set on 0

Display off

N

o supply

The flat cable inside the control panel

is not connected

MAXIMUM CURRENT

motor 1 and 2 alarm

Maximum current set on the setup less

than that absorbed by the motor

Motor blocked or damaged

Set manually the maximum current the 25%

more than the nominal value

Disconnect the motor and be sure

it is working properly

Application SEWAGE/CLEAN WATER:

FLOAT SWITCHES OFF

with full tank

Ceck the functionality of the float switches

and of the cable and replace if necessary

Possible failure of the float switches

or connection cable interrupted

Application 4-20mA bar:

Pressure value in bar displayed

in the wrong display

Clean carefully the pressure transducer

or

replace if necessary

Possible obstruction or failure of the

4-20mA pressure transducer

Application 4-20mA meters:

The displayed level

in meter is wrong

Clean carefully the piezoresistive probe

or

replace if necessary

Possible obstrution or failure of the

piezoresistive probe 4-20mA

Ceck the functionality of the pressure switches

and of the cable and replace if necessary

35