Calibration and Measurement

5

STRIP POSITIONING AND MEASUREMENT TECHNIQUES

You should refer to the documentation for the software program that you are using with your instrument. All applications

that utilize the instrument will require that you have the software running during strip measurements. The following

information is provided to familiarize you with the “mechanical” requirements of guiding a strip through the instrument.

MEASUREMENT NOTE:

The strip must have a 1.5” (38.10mm) leader before the leading edge of the first step (contact X-Rite Applications Support

if additional information is required). Inspect the strip for spots or defects on the step. Defects may cause inaccurate

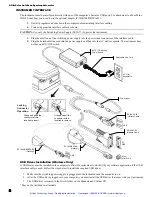

measurements. Position the strip so that the group of patches to measure is directly under alignment mark on the cover.

Insert the leading edge of the strip past the front idler rollers until it stops against the rear drive rollers (approximately three

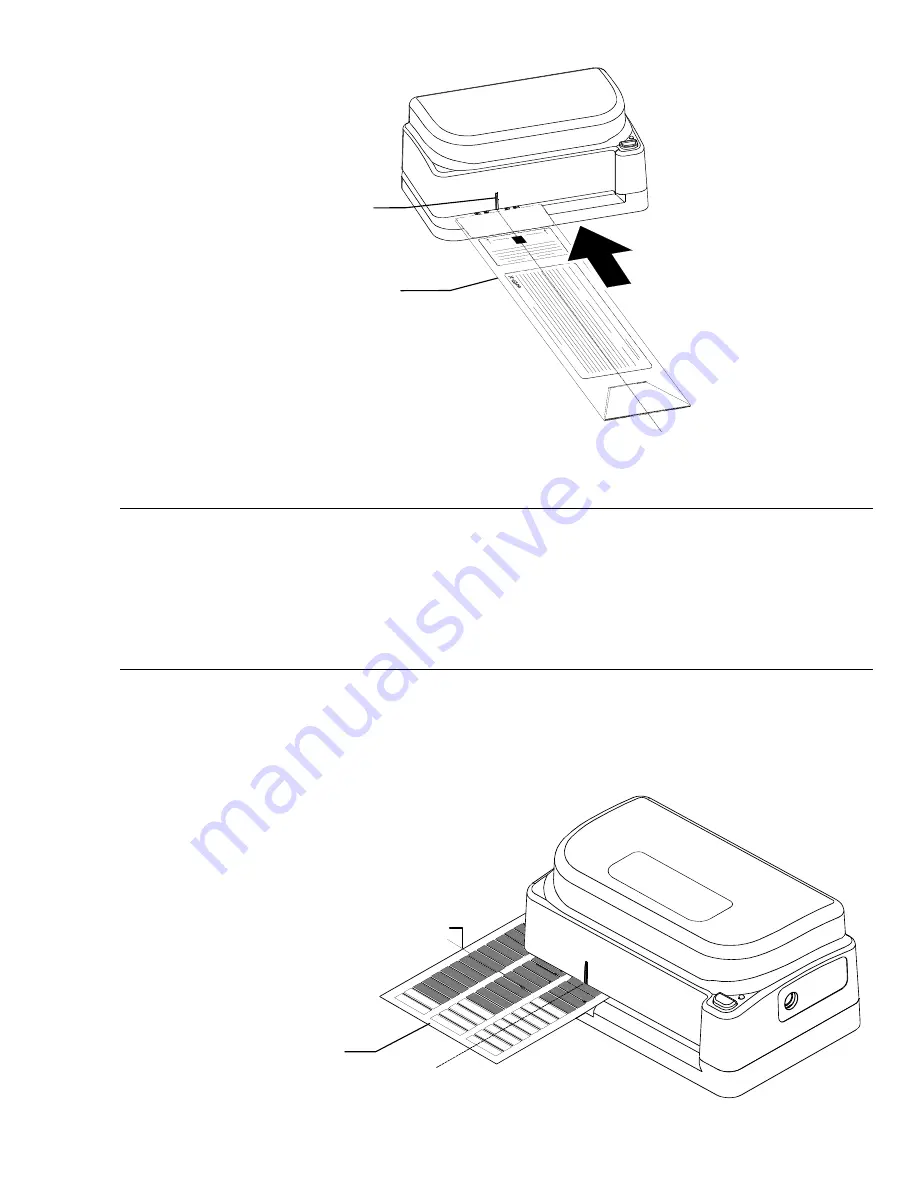

inches). Press the Instrument button, the motor activates and automatically pulls the strip through the instrument. For large

strips (media that extends outside the left side of the cover), guide the strip with slight pressure. This prevents skewing of

the strip as it is measured. Do not “tug” forwards or backwards on strip while internal motor is pulling strip through.

1.

Select strip type to measure from software.

2.

If required, initiate reading by pressing Instrument button. LED indicator should flash green slowly during reading.

3.

Position the strip so that the patches to measure are directly under alignment mark. Insert the strip past the front idler

rollers until it stops against the rear drive rollers. Press the Instrument button to activate reading.

4.

Verify that the strip was read successfully by viewing the computer monitor. If an error message is noted, try re-

measuring strip.

Alignment mark

Insert strip until it stops against the rear drive

rollers and press Instrument button

When measuring large strips, guide

along outside edge

Slowly insert envelope until it

stops against the drive rollers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Summary of Contents for AutoScan DTP41 Series

Page 3: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Page 7: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Page 16: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...