C i 7 X X 0 B E N C H T O P S P E C T R O P H O T O M E T E R

27

3.

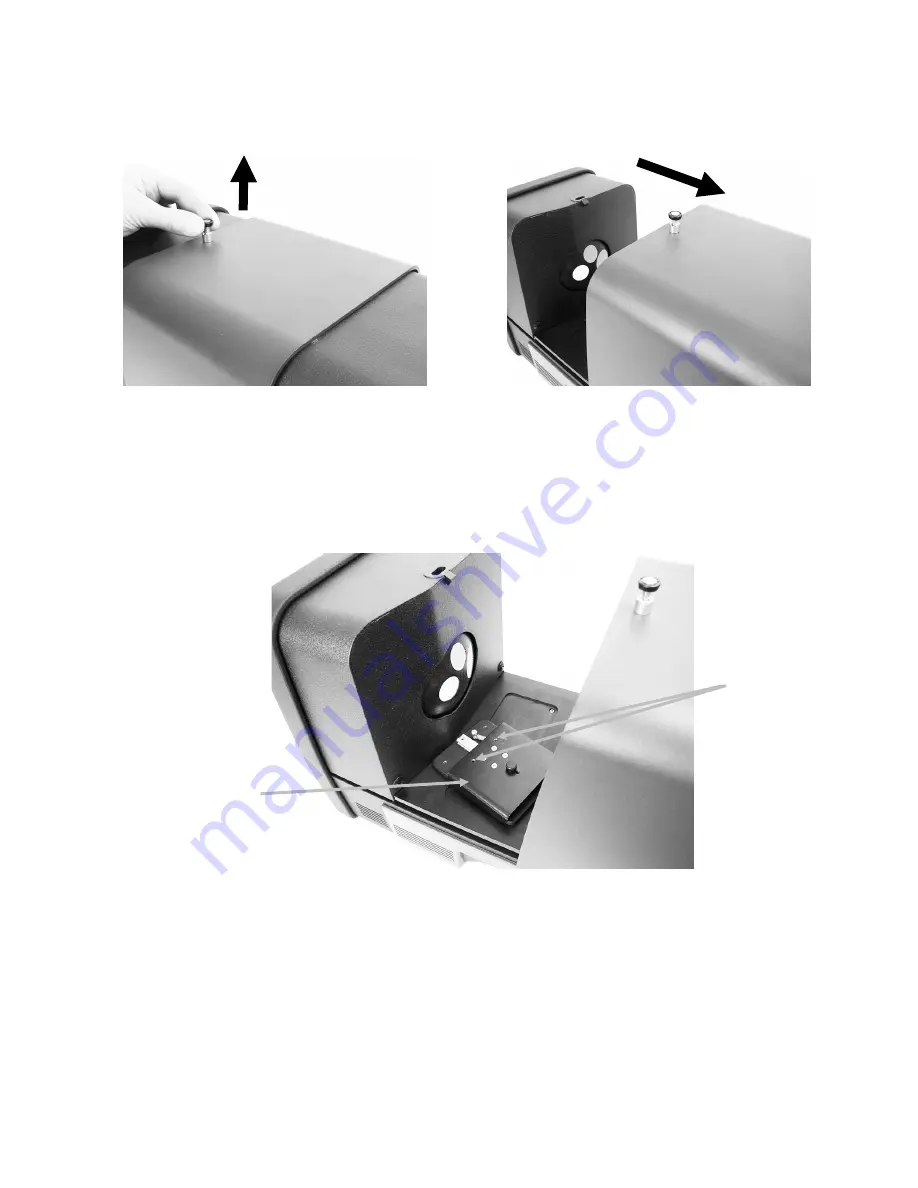

Open the transmission cover by lifting up on the locking pin while sliding the cover to the

back.

4.

Align the sample holder base plate pins to the base plate mounting channel holes inside the

transmission area.

Position the base plate with the clamp mounting holes on the sphere side. Be careful to get

the angle correct. Care should be taken to properly align the base plate so that the sample is

positioned between the stop and clamp toward the sphere.

5.

Attach the appropriate sample stop to the base plate and clamp to the carriage base with the

thumb screws. We recommend using a stop plate with all sizes including 25 mm.

The sample is held in position using a sample stop on the sphere side of the sample, and a

spring loaded clamp on the side of the sample away from the sphere.

Care should be taken to properly align this holder so that the stop plate is positioned flush

and tight against the opening in the sphere. Do not tighten the thumb screws until the

sample has been positioned tight against this opening.

Lens Side

Sphere Side

Clamp mounting holes

Base plate in total

transmission position