iCPlate2

EN

25

Important:

In normal circumstances the reference

value is set to be equal to the nomi-

nal value to obtain a linear plate copy.

However, for certain applications a plate

type dependent process calibration

(pre-compensation) on the plate copy

may be desirable. In this case iCPlate2

offers the possibility of defining the

reference curve in deviation from the

45° straight line.

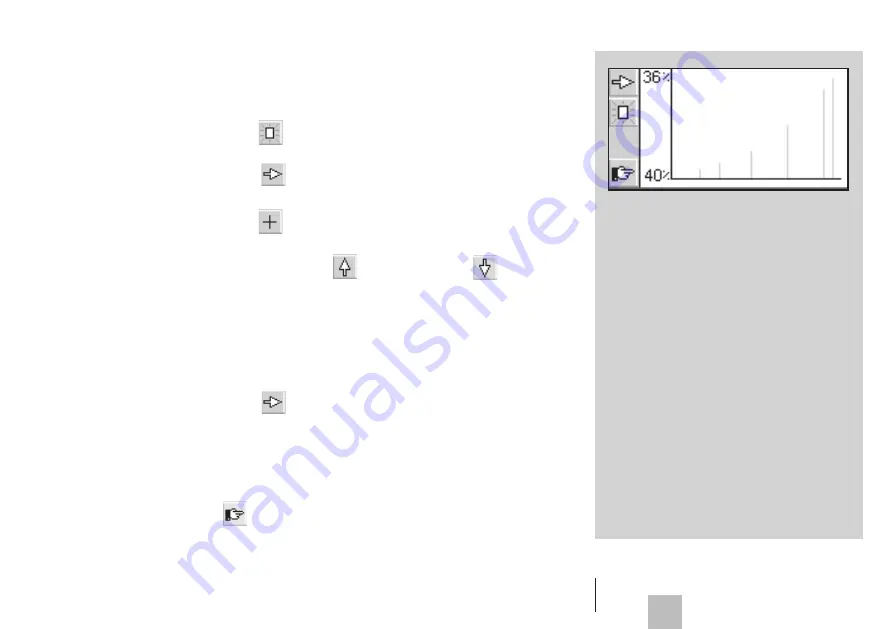

Example: Inputting a reference curve with the sampling points 5, 10,

30, 60 and 90.

• Select the reference curve window from within the settings window.

• Select the function with the <UP> or <DOWN> button and

execute this using the <ENTER> button. All reference values are reset.

• Select the function and execute this function repeatedly until the

nominal value is equal to 5% (press <ENTER> button 5 times).

• Select the function .

• The default value for this sample point corresponds to the nominal

value. Now select the function to increment or to decrement

and press the <ENTER> button. If the reference curve is altered at

least once, the iCPlate2 will create a sample point for the reference

curve in this position and save this. The vertical gray line at this

location in the diagram is adjusted simultaneously when the reference

value is changed.

• Select the function and execute this function repeatedly until

the nominal value is equal to 0% (press <ENTER> button 5 times).

• Change the reference value using the steps described for 5%.

• Set further reference values in the same way.

When all of the desired settings have been made, change to the standard

window by using

Summary of Contents for iCPlate2

Page 1: ...iCPlate2 EN iCPlate2 Plate Measuring Device User Guide Edition 2 1 ...

Page 2: ......

Page 6: ......

Page 12: ......

Page 14: ......

Page 38: ...iCPlate2 38 ...