ENCORE

7

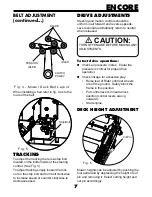

When installing a belt refer to fig. 4 as to the

route of the belt.

BELT ADJUSTMENT

(continued...)

TRACKING

To adjust the tracking there is a stop bolt

located on the bottom side of the steering

control. (See Fig. 5)

To adjust tracking simply loosen the lock

nut on the stop bolt and turn bolt clockwise

to increase speed or counter clockwise to

decrease speed.

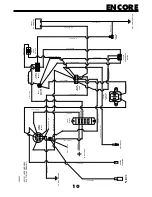

DRIVE ADJUSTMENTS

Steering and motion controls should be

uniform in all forward and reverse speeds.

Levers should automatically return to neutral

when released.

CAUTION:

TURN OFF ENGINE BEFORE MAKING ANY

ADJUSTMENTS.

To test drive operations:

Check air pressure in tires. Equal tire

pressure is critical for proper drive

operation.

Check linkage for excessive play.

•

Raise rear of Rider until rear wheels

are off the ground. Safely block the

frame in this position.

•

Put control levers in neutral lock

position (control levers swung

outward).

•

Start engine.

DECK HEIGHT ADJUSTMENT

Mower heights can be adjusted by pushing the

foot pedal and by depressing the height of cut

pin and removing it. Select cutting height and

set pin accordingly.

TENSION

IDLER

BLADE

IDLER

CLUTCH

PULLEY

Fig. 4 - Mower Deck Belt Layout

Fig. 5

Stop Bolt

Cut Pin

CU

TT

IN

G

H

EIG

HT

Fig. 6

Summary of Contents for 48K19X

Page 1: ...OPERATORS MANUAL 48K19X ...