- 1 -

PLEASE READ THIS MANUAL BEFORE

USING YOUR NEW X-TRONIC Model

#3020-XTS SOLDERING STATION

This manual is provided to make a safe and effective use of the X-Tronic

3020-XTS soldering station and to maintain this instrument in proper

working condition. Be sure to keep this manual in a handy place near the

unit for future reference.

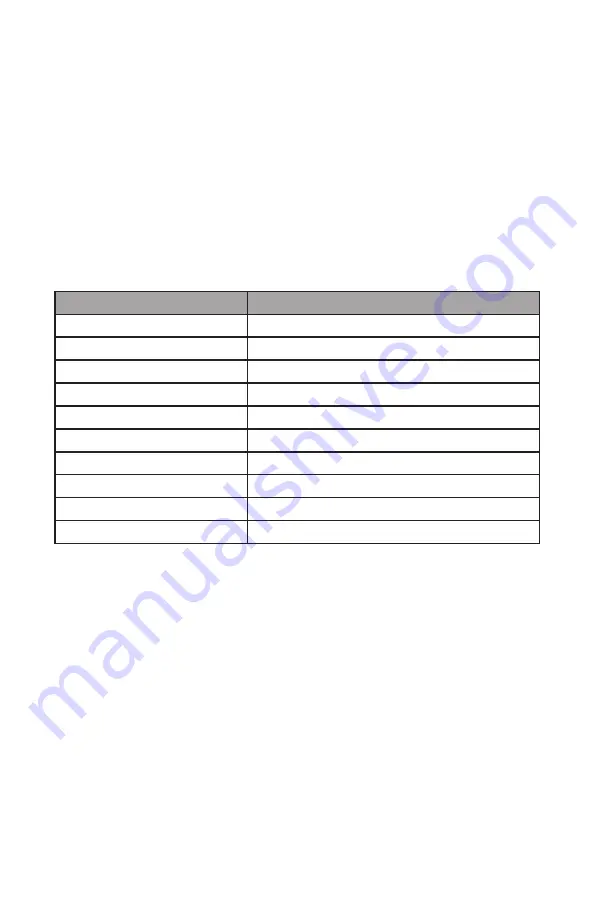

PRODUCT SPECIFICATIONS

Model

XTR-3020-XTS

Dimensions (assembled)

7.5” L x 5.5” W x 10” H

Weight

1.5 lbs

Working Environment

32°F ~ 104°F / 0°C ~ 40°C

Storing Environment

-4°F ~ 176°F / -20°C ~ 80°C

Storage Humidity

35% - 45%

Temperature Range

392°F ~ 896°F / 200°C ~ 480°C

Temperature Stability

± 3.6°F / 2.0°C (Static)

Grounded Tip Voltage

< 1 mV

Tip Impedance

< 1Ω

Cord Length

≥ 40 in

PACKAGE CONTENTS

• Main Power Unit with LED Display

• 75 Watt Soldering Iron with Ergonomic Grip

• Attachable Helping Hands (set of two)

• Small Wrench (to Tighten Helping Hands)

• Spring Steel Soldering Iron Holder

• Solder Roll Holder (attaches to side of main unit)

• Brass Sponge Soldering Tip Cleaner with Cleaning Flux

• Wet Sponge Soldering Tip Cleaner