- 7 -

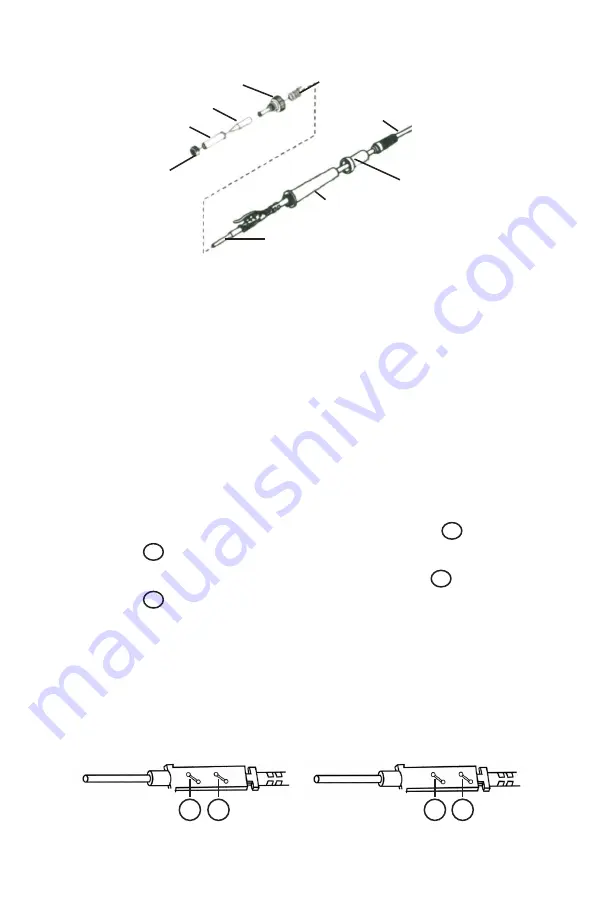

REPLACING THE SOLDERING IRON HEATING ELEMENT

Cord

Soldering Tip

Collar

Metal Tip

Retaining

Screw Cap

Bakelite Screw Cap

Spring

Heating

Element

Ergonomic

Grip

Handle

1. Turn off the unit and unplug it from the outlet. Allow the soldering

iron to cool down to room temperature.

Never attempt to handle the tip while the iron is hot.

2. Unscrew the Black Bakelite Screw Cap and slide off the full tip

assembly.

3. Push the Cord through the bottom of the soldering iron while

simultaneously pulling gently on the heating element to expose the

heating element circuit board.

4. De-solder the 2 Thin (red or white) wires and the 2 Thick (blue)

wires that have heat shielding on them from the circuit board and

pull the heating element away from the board.

Please take note of the location of the wire thickness/color for

installation of new heating element (see diagram below).

5. On one side of the circuit board solder a thin wire to

1

and a thick

wire to

2

(see diagram below).

6. Flip the circuit board over and solder a thin wire to

3

and a thick

wire to

4

(see diagram below).

7. Pull the cord back gently and align the circuit board to the slots on

the iron so the cord can be pulled back to its original position.

8. Replace black Bakelite Screw Cap and screw back on and hand

tighten -

Do NOT over-tighten.

9. Install the soldering tip, slide the metal soldering tip retaining collar

and hand tighten it. Plug the AC cord back into a grounded outlet.

SIDE A

SIDE B

1

2

3

4

NOTE: The wires on the heating element can be soldered onto either

side of the circuit board, as there is no polarity for the element.