System Operation

Cartridge Installation

820-0332

4-9

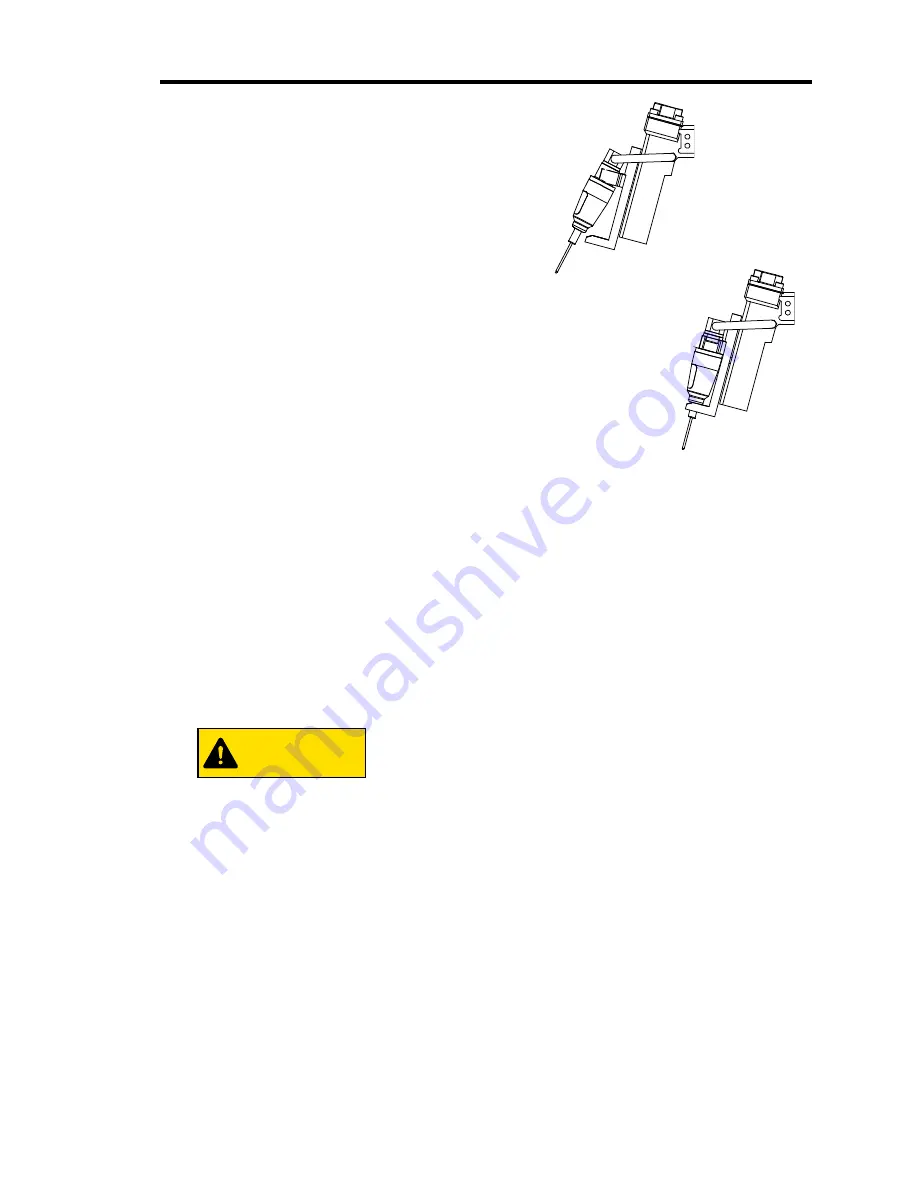

3.

Press top of cartridge into shuttle spring clip.

4.

Press cartridge body into shuttle forks until the neck fully snaps

into place.

Cartridge is now ready for priming. (See “

Cartridge Priming

" later in this Section (4) for

instructions)

Caution: Ink Cartridge needle can pierce skin when

moved manually or when shuttle valve is actuated:

1.

Keep hands and fingers clear of the cartridge

needle tip after cartridge change out and

priming.

2.

Never place hands or fingers under the cartridge

needle

3.

Keep hands and fingers clear of needle tip

during cartridge change out and priming.

Always follow recommended cartridge priming

procedure. Place the controller toggle switch in

RUN position and press the controller RESET

button, which fires ONLY the cartridge valve to

send ink to the needle tip. Priming using any

other mode that actuates the shuttle valve during

the priming process exposes the user to possible

hand or finger puncture when the shuttle

actuates.

CAUTION

Summary of Contents for 340-7110

Page 10: ...1 2 820 0332 This page is intentionally left blank...

Page 18: ...Controller Installation Installation 3 6 820 0332 This page is intentionally left blank...

Page 34: ...Cartridge Priming Tips System Operation 820 0332 4 16 This page is intentionally left blank...

Page 40: ...Ink Removal Information Ink 820 0332 5 6 This page is intentionally left blank...