820-0332

6-1

Maintenance & Troubleshooting

Ink Troubleshooting

This Troubleshooting section for the Micro-Z Pneumatic Inker is divided into three parts. The first part

covers Ink and the DM-2 ink cartridge. The second part covers the Inker Assembly, and the third part covers

the Pneumatic Controller. More troubleshooting information is available in the “Support” section at

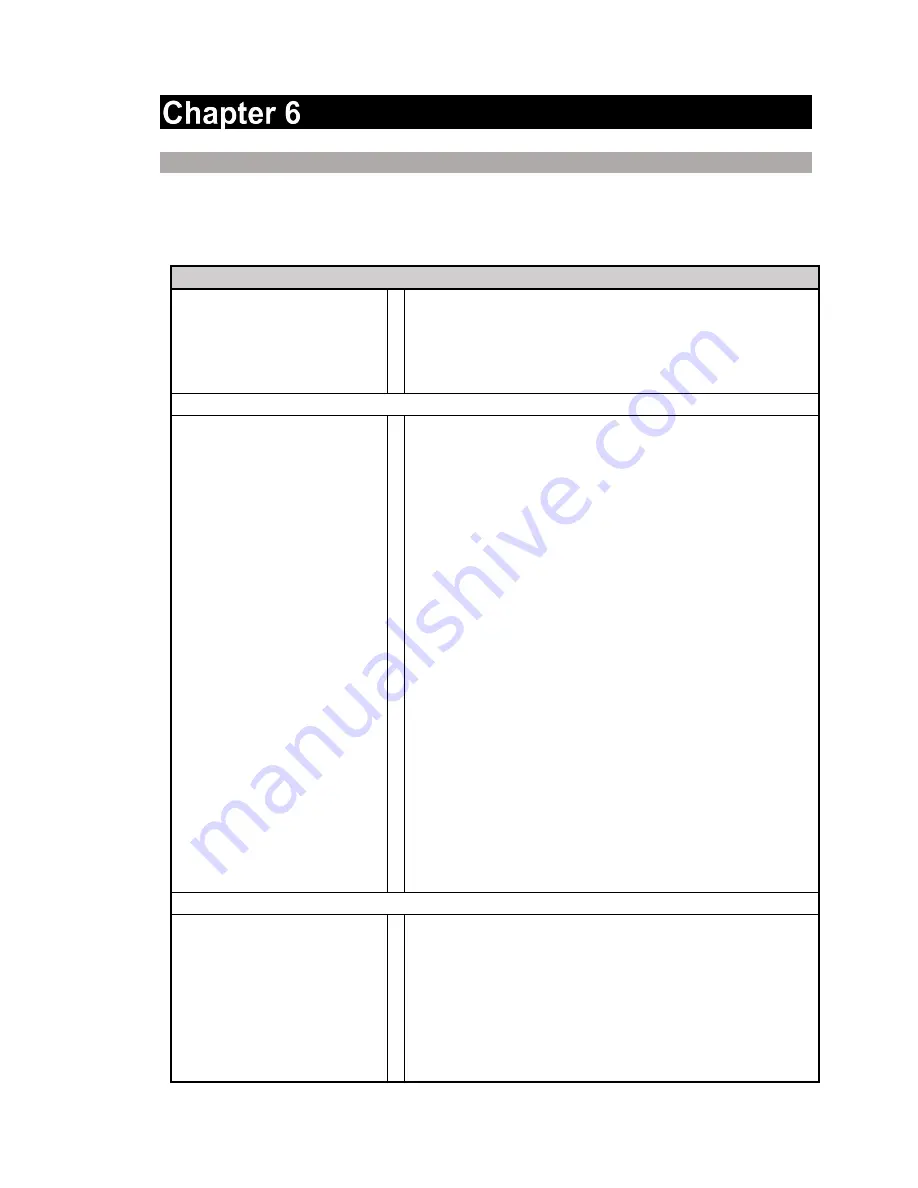

Problem

Solution

Some ink dots tend to crack

after baking using Xandex

recommended cure cycles.

This occurrence is related to the ink surface tension, the

wafer surface conditions and too long a delay time

between inking and curing. To remedy this situation, the

curing cycle has to be modified (reduce time and

temperature). See

Section 5 “Ink Curing.”

Runny, blobbing ink or

skipping dots.

1.

Check ink shelf life. 6990, 6993, 6997 inks should

be used within 4 months or 5 days of cartridge

opening. 8103 and 8104 air dry glycol free inks

should be used within 4 months or 3 days of

cartridge opening. 7824 and 7824T air-dry ink

within 4 months or 3 days after cartridge opening.

2.

Check for exposure to extreme temperatures.

Cartridges should be stored at 25°C.

DO NOT

refrigerate the cartridges.

Occasionally, ink is

subjected to much higher temperatures (40-50° C)

for an extended time during transport. This could

break down the ink such that its viscosity and

surface tension are altered permanently.

3.

Z height adjustment is incorrect. After cartridge

replacement, minor Z height adjustment may be re-

quired. See

Section 4 “Inker Assembly Setup and

Alignment.”

4.

Chuck top or wafer surface not planar. Verify

planarity of both.

After changing the

controller dot size settings,

the dots are too small or the

ink blobs at the tip of the

needle.

1. The cartridge tip may be damaged. Examine

cartridge and replace if necessary.

2.

Whenever dot size is changed there may be minor Z

height adjustments required. The inker should be

set so that just the bottom of the ink drop touches

the wafer.

Summary of Contents for 340-7110

Page 10: ...1 2 820 0332 This page is intentionally left blank...

Page 18: ...Controller Installation Installation 3 6 820 0332 This page is intentionally left blank...

Page 34: ...Cartridge Priming Tips System Operation 820 0332 4 16 This page is intentionally left blank...

Page 40: ...Ink Removal Information Ink 820 0332 5 6 This page is intentionally left blank...