Defender XD103- User Manual

VI Troubleshooting

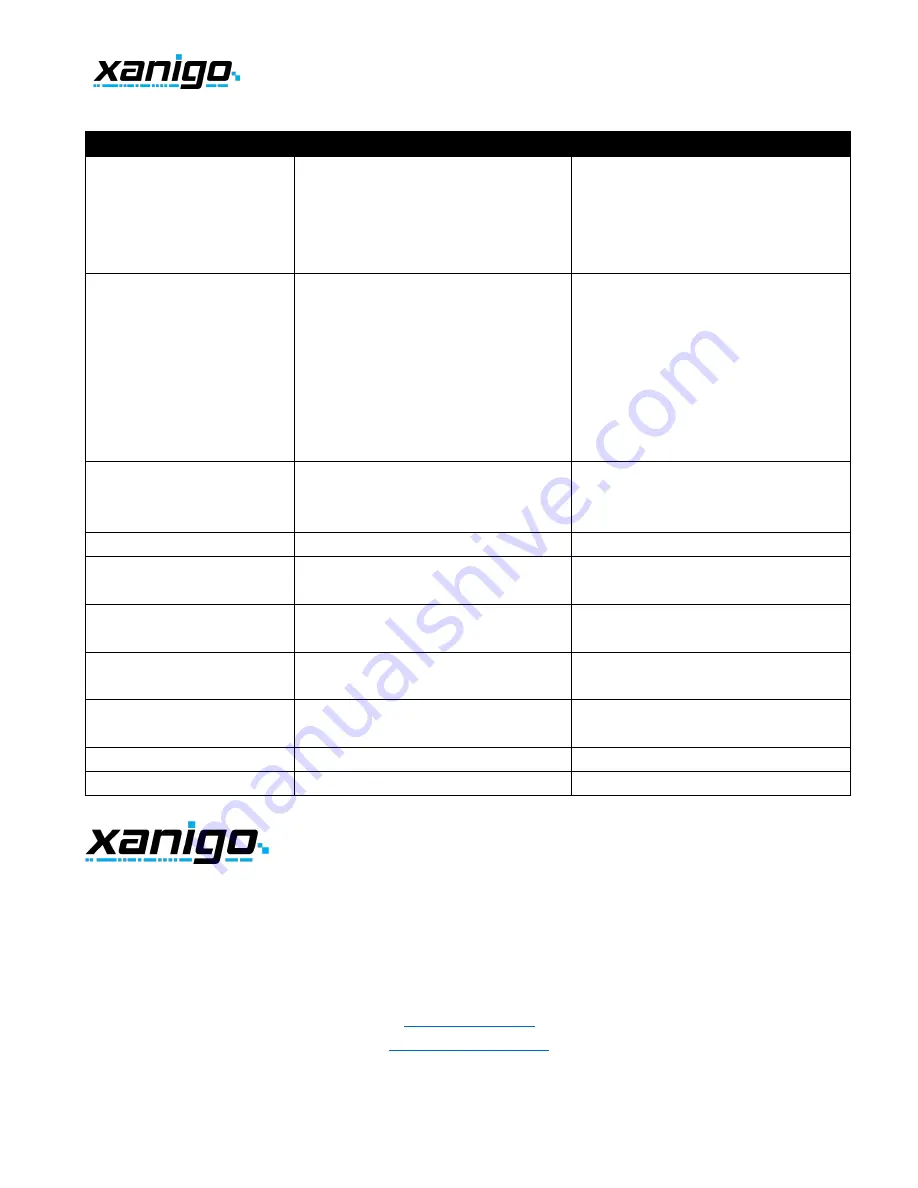

Problem

Cause

Solution

A. little or no material flow

1. nozzle clogged

2. suction tube clogged

3. material volume setting turned too far to the right

4. suction tube loose

5. container is loose

1. clean

2. clean

3. turn to the left

4. insert

5. tighten the container

B. material leaking

1. nozzle loose

2. nozzle worn

3. nozzle seal worn

4. material build-up on spray pattern dial and nozzle

5. atomizer used or stored in an inverted or sideways

orientation

1. tighten

2. replace

3. replace

4. clean

5. disassemble atomizer from motor/blower

assembly and used compressed air to remove liquid

from atomizer assembly. If liquid has entered motor

/blower assembly replace motor/blower assembly.

C. atomization is too coarse

1. material volume setting too far to the left

2. nozzle clogged

3. too little pressure build-up in container

1. turn to the right

2. clean

3. tighten container

D. spray jet pulsates

1. material in container is depleted

1. refill

E. pattern runs, sags or remains wet

1. applying too much material

1.adjust material flow or increase movement of

atomizer

F. too much over-spray

1. atomizer too far from target area

2. too much material applied

1. reduce distance

2. turn material volume setting to right

G. pattern is very light and splotchy

1. moving the atomizer too fast

1. adjust material flow or decrease movement of

atomizer

H. large cloud of disinfectant

1. atomizer too close to target area

1. move atomizer away from target area

and reduce disinfectant flow

I. disinfectant not drying

1. atomizer too close to target area

1. move further away (4 feet or greater)

J. disinfectant drying too quickly

1. atomizer too far away from target area

1. move closer

Xanigo, llc

3236 Huntington

Weston, FL 33332

https://xanigo.com

Contact Us

(800) 514-7837

07/2021