18

●

Piercing

Hold the torch at an angle to the work piece,

pull the trigger to start the arc and slowly

rotate it to an upright position.

When sparks are exiting from the bottom of

the work piece, the arc has pierced through

the material.

When the pierce is complete, proceed with

cutting.

●

Safety Trigger Operation

The Suregrip SC40 torch supplied with the Viper Cut 30 machine has a new design of safety trigger.

Just pull back on the trigger whilst increasing your grip and you will feel the trigger move to the on position.

When you release the pressure it will return to the off position.

off

on

off

Lubrication Procedure:

●

Remove the retaining cap, cutting tip, and swirl ring,

keep the electrode on the torch head.

●

Apply grease as shown in the drawing, and then push

the electrode up and down for 10-20 times.

●

Remove the excess grease before assembling the torch.

Torch Head Electrode Holder Lubrication:

●

Apply in case of sticking or start/stop is delayed.

●

Appy after a period of prolonged inactivity.

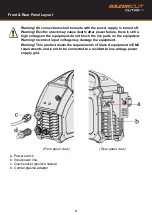

Fig 1

: Show's the electrode and tip position when not

in use.

Fig 2

: At the point the safety trigger is actuated, current

flow is sent through the torch. This is followed by

a pressurized gas flow which causes a piston

action to take place in the torch head. The tip and

electrode are separated causing a "strike" and the

pilot arc is initiated.

Fig 3

: When the torch head is placed in proximity to the

work piece the plasma cutting jet is ignited.

*

Your plasma torch is supplied with a tube of Silicon Grease, this

grease is used to lubricate the piston shaft of the torch head.

Surecut

™

Patented Arc Ignition System

Lubrication instruction

10-20

Times

Fig 1

Fig 2

Fig 3

*

Operating Procedure & Techniques

for PLASMA Cutting