19

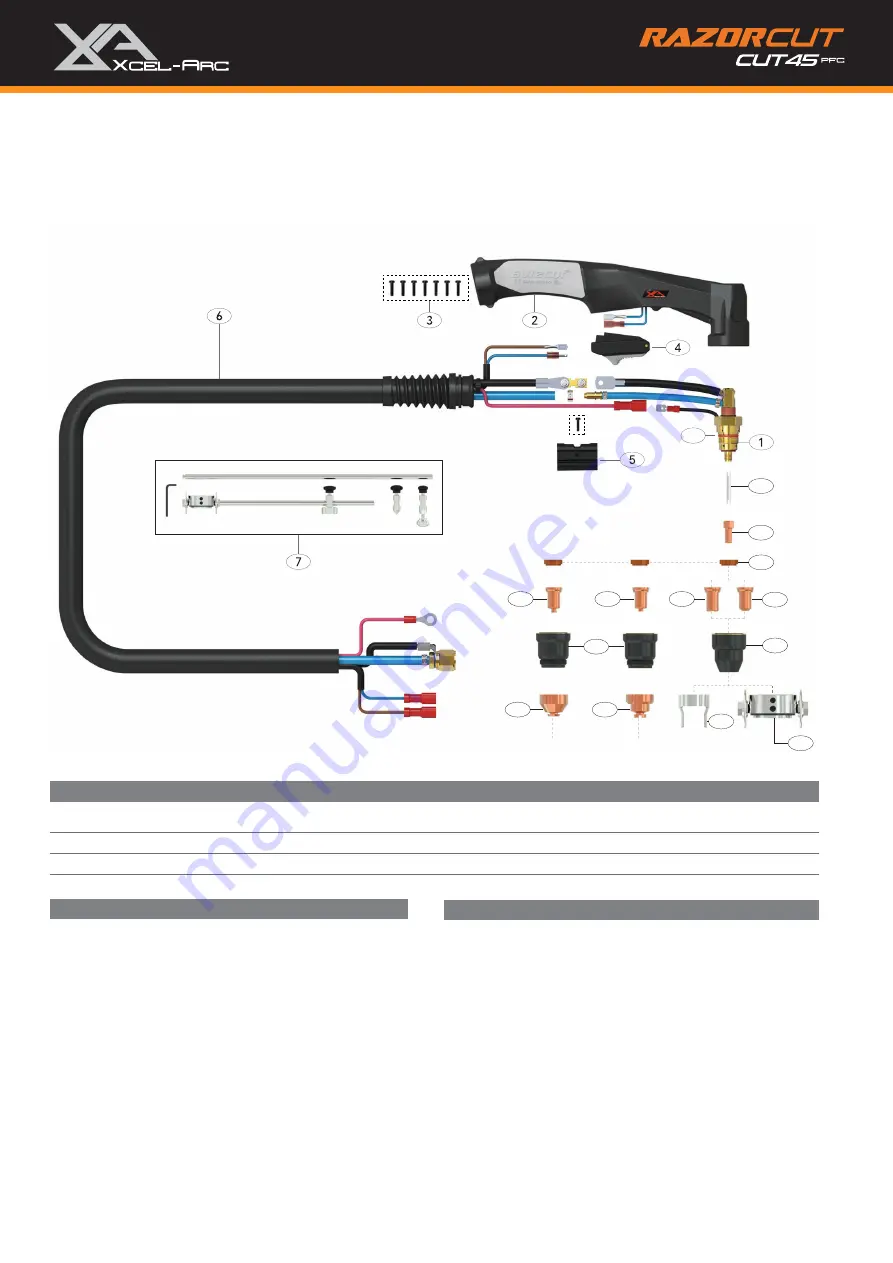

Spare Parts

#

Part Number

Description

SC80-60-CC1

Surecut 80 Plasma Torch x 6m

SCM80R-60-CC1

Surecut 80 Machine Torch x 6m

1

SC8001

SC80 70 Torch Head Kit

2

SC8014

Plasma Handle Kit

3

SCSP1

Screw Pack

4

SC2516

Plasma Safety Trigger

5

SC8015

Location Block

6

SC8019-60-CF4

Cable Assembly Complete x 6mt

7

SC8050

Circle Cutting Attachment Kit

8

SC8002

Cooling Tube

9

SC8004

Electrode

10

SC8006

Swirl Ring

11

SC8020-10

Cutting Tip 1.0mm

Spare Parts

#

Part Number

Description

SC8020-13

Cutting Tip 1.3mm

11a

SC8022-09

Cutting Tip 0.9mm Cross Groove

12

SC8026-10

Contact Cutting Tip 1.0 mm, 40-50A

SC8026-11

Contact Cutting Tip 1.1 mm, 50-60A

SC8026-12

Contact Cutting Tip 1.2 mm, 60-70A

SC8026-13

Contact Cutting Tip 1.3 mm, 70-80A

13

SC8028-16

SC80 Gouging Tip 1.6mm

14

SC8030

Retaining Cap

15

SC8031

Shield Cap Body

16

SC8051

SC80 Cutting Buggy

17

SC8040

SC80 Stand Off Guide

18

SC8041

Contact Cutting Shield Cap

19

SC8043

Gouging Shield Cap

Technical Data

Max Current 80A

Gas Pressure

4.5-5.0 Bar (65-75psi)

Duty Cycle

60%

Gas Flow

110 l/min

Gas

Air/N

with Pilot Arc

Rating: 80A Air/N2 Gas, @ 60% duty cycle.

For use on

RAZOR

CUT 40Air,

CUT45 & CUT80

Surecut SC80

Surecut SC80

Contact cutting

Gouging

Stand off cutting

1a

13

12

8

9

10

11

14

16

17

19

18

11a

15