XCT80 Truck Crane Operation Manual

10-1

Crane operation

Chapter 10

Chapter 10 Crane operation

10-1 Crane operation preparations

10-1-1 Check before crane runing

10-1-2 Crane operation conditions

check

Two conditions of the safe use of the

crane: good state equipments and well trained

operators.

1. Detailed reading the engine speci

fi

cation

relating to its start and stop section.

2. Check the hydraulic oil level of crane

and ensure that the hydraulic oil quantity

reaches a prescribed value.

3. Check any components state, con

fi

rm no

abnormal phenomenon and strictly forbidden

for operating under abnormal conditions.

4. After starting the engine, it runs with

slow speed and idling to make the engine full

preheating.

5. Before switch on the power take-off

device, one must confirm that any operation

h a n d l e s a n d s w i t c h e s a r e l o c a t e d i n t h e

"medium" or "off" position.

6. When the operation without load, ensure

that any control handles and switches have no

abnormal phenomenon, and strictly forbidden

for operating under abnormal conditions.

7. Before operating the torque limiter,

it should be pre-checked (see "torque limiter

manual").

8. Check all safety devices (such as alarm

indicator lamp) with or without abnormal

phenomenon.

The crane operators must obtain or trying

to investigate the following conditions before

driving the crane to the construction site:

1. Operation type;

2. Construction site( distance);

3. Passing height and road width along the

way;

4. Wire case overhead the operation ;

5 . O p er atin g co n d itio n s limit d u e to

surrounding buildings;

6. Weight and shape size of the lifting

heavy;

7. Lifting and falling height;

8. Foundation bearing capacity, etc.

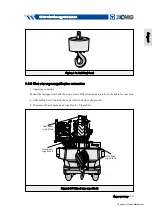

After obtaining these details, the crane

operator can determine to mount the necessary

lifting device and master the lifting working

conditions: such as the lifting hook; the auxiliary

boom; the support pad; the operating route

selection; approval of driving the crane.

If the driver does not master the necessary

lifting working conditions, it is difficult to finish

the task successfully. Therefore, before the

operation, the operator should do well all kinds of

preparation work to prevent accidents.

9. Before the crane operation, the power

switch should be turned off in operating room of

lower crane portion.

Summary of Contents for XCT80

Page 1: ...Courtesy of CraneMarket com...

Page 10: ...XCT80 Truck Crane Operation Manual VIII Courtesy of CraneMarket com...

Page 14: ...XCT80 Truck Crane Operation Manual 1 2 LOG Chapter 1 Courtesy of CraneMarket com...

Page 20: ...XCT80 Truck Crane Operation Manual 2 6 LOG Chapter 2 Courtesy of CraneMarket com...

Page 31: ...XCT80 Truck Crane Operation Manual 3 11 LOG Chapter 3 Courtesy of CraneMarket com...

Page 32: ...XCT80 Truck Crane Operation Manual 3 12 LOG Chapter 3 Courtesy of CraneMarket com...

Page 47: ...XCT80 Truck Crane Operation Manual 4 15 LOG Chapter 4 Courtesy of CraneMarket com...

Page 48: ...XCT80 Truck Crane Operation Manual 4 16 LOG Chapter 4 Courtesy of CraneMarket com...

Page 80: ...XCT80 Truck Crane Operation Manual 5 32 LOG Chapter 5 Courtesy of CraneMarket com...

Page 104: ...XCT80 Truck Crane Operation Manual 6 24 LOG Chapter 6 Courtesy of CraneMarket com...

Page 124: ...XCT80 Truck Crane Operation Manual 7 20 LOG Chapter 7 Courtesy of CraneMarket com...

Page 142: ...XCT80 Truck Crane Operation Manual 8 18 LOG Chapter 8 Courtesy of CraneMarket com...

Page 176: ...XCT80 Truck Crane Operation Manual 9 34 LOG Chapter 9 Courtesy of CraneMarket com...

Page 206: ...XCT80 Truck Crane Operation Manual 10 30 LOG Chapter 10 Courtesy of CraneMarket com...

Page 215: ...XCT80 Truck Crane Operation Manual 11 9 LOG Chapter 11 Courtesy of CraneMarket com...

Page 216: ...XCT80 Truck Crane Operation Manual 11 10 LOG Chapter 11 Courtesy of CraneMarket com...

Page 235: ...XCT80 Truck Crane Operation Manual 12 19 LOG Chapter 12 Courtesy of CraneMarket com...

Page 236: ...XCT80 Truck Crane Operation Manual 12 20 LOG Chapter 12 Courtesy of CraneMarket com...

Page 241: ...XCT80 Truck Crane Operation Manual 13 5 LOG Chapter 13 Courtesy of CraneMarket com...

Page 242: ...XCT80 Truck Crane Operation Manual 13 6 LOG Chapter 13 Courtesy of CraneMarket com...

Page 244: ...XCT80 Truck Crane Operation Manual 14 2 14 1 Appendix Chapter 14 Courtesy of CraneMarket com...

Page 249: ...XCT80 Truck Crane Operation Manual 14 7 LOG Chapter 14 Courtesy of CraneMarket com...

Page 250: ...Powered by TCPDF www tcpdf org Courtesy of CraneMarket com...